Steel Drywall Studs with smart edge™ technology

ProSTUD Drywall Framing System (ProSTUD® and ProTRAK®) with Smart Edge™ Technology is the innovative steel drywall stud that sets a new industry benchmark for high performance. Its patented design combines high-strength steel with additional stiffening enhancements for a drywall framing stud previously unimagined.

When we set out to develop this revolutionary drywall framing system, we wanted it to be the best and the most innovative. So, we called in the pros – the guys that work with the product day in and day out. ProSTUD Drywall Framing was developed, tested and approved in the field. The result? Drywall framing performance designed by the pros for the pro.

What’s more, ProSTUD Drywall Framing is backed by comprehensive laboratory testing for strength, fire and sound. No other drywall framing system has been as thoroughly tested as ProSTUD. So not only is it a dream to work with, but it also has the performance to meet the requirements of today’s building codes. ProSTUD is available nationwide.

U.S. Patent No. 9,010,070

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about ProSTUD Drywall Framing Products.

ProSTUD Profile Information

Web widths: 1-5/8" (162), 2-1/2" (250), 3-1/2" (350), 3-5/8" (362), 4" (400), 5-1/2" (550), & 6" (600)

Flange: 1-1/4"

Lip: Varies by stud size

Smart Edge™ Technology

Material Thicknesses:

- ProSTUD 25 / 15mil (25ga EQ) 50ksi

- ProSTUD 20 / 18mil (20ga EQ) 70ksi

- ProSTUD 30MIL 33ksi

- ProSTUD 33MIL 33ksi

Coatings:

- G40EQ is standard, G40 available on request.

- Other coatings available as special order: G40EQ DiamondPlus®, G60 and G90.

- G40EQ Diamond Plus is only available in select markets and thicknesses. Contact your ClarkDietrich Sales Representative for market availability.

ProTRAK Profile Information

Web widths: 1-5/8", 2-1/2", 3-1/2", 3-5/8", 4", 5-1/2", & 6"

Legs: 1", 1-1/4", 1-1/2", 2", 2-1/2", & 3"

Not all combinations of web,leg and gauge are available. Contact your local sales office for details.

Material Thicknesses:

- ProTRAK 25 / 15mil (25ga EQ) 50ksi

- ProTRAK 20 / 18mil (20ga EQ) 50ksi

- ProTRAK 30MIL 33ksi

- ProTRAK 33MIL 33ksi

Coatings:

- G40EQ is standard, G40 available on request.

- Other coatings available as special order: G40EQ DiamondPlus®, G60 and G90.

- G40EQ Diamond Plus is only available in select markets and thicknesses. Contact your ClarkDietrich Sales Representative for market availability.

Construction Advantages:

- High strength steel combined with low-profile flange stiffening grooves and double offset web planking increases strength and provides greater limiting heights

- Diamond embossed web creates stiffness, reducing flange fade and screw spinout during drywall installation

- Strong, lightweight stud and track cuts and handles easier than conventional flat steel studs

- Flange grooves provide sight line for drywall alignment and aid in positioning screws at drywall joint to maintain the 3/8" edge requirement

- Web and leg enhancements in ProTRAK® provide straight and rigid members, making it the best choice for framing walls, headers, soffits, and bulkheads

Design Advantages:

- Designed to meet the additional strength requirements of today’s building codes:

- IBC 2024, AISI S100, S220, S916 and ICC-ES AC46 and AC86

- UL Classified with listing in over 50 designs, including U419, V438, and chase wall assemblies

- Exceptional sound performance in over 50 tested sound assemblies

- Independent Product Certification: Intertek - CCRR 0207

- Can contribute LEED® points in LEED v4.1 or v4. EPD and HPD verifications also available.

- National availability

Limitations of Use

- ProSTUD is designed for interior non-load-bearing walls only.

- Do not stack

Limiting Heights

Which ProSTUD® limiting height tables should I use?

ProSTUD, like any interior drywall stud, may be used in a variety of applications including walls, ceilings, and soffits. While some conditions may require the expertise of a design professional, many assemblies can be selected based on tabulated data. Locate the required assembly below and follow the instructions for selecting the proper ProSTUD member.

Learn more from a On-Point Interview With Patrick W. Ford P.E., S.E., Technical Director, SFIA

SFIA Technical Publication

Interactive iProSTUD online tool

iProSTUD (part of ClarkDietrich iTools) provides direct links to UL design reports, third-party STC sound tests and SubmittalPro®, where online users can view technical data sheets and generate submittals.

Filter ProSTUD wall systems by:

- Wall design

- Wall assembly

- limiting heights

- STC sound ratings

- UL fire protection

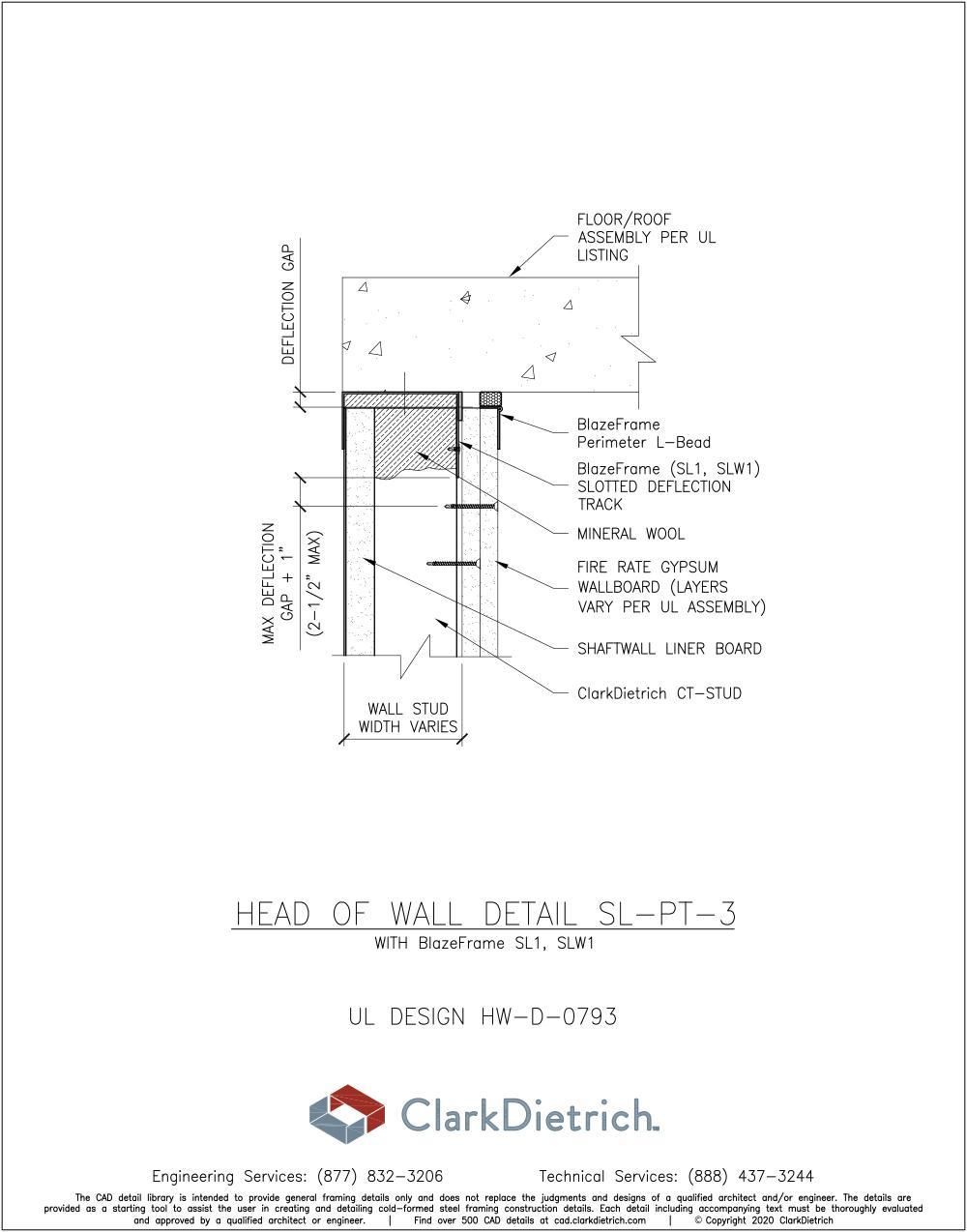

(NEW) Head-of-Wall Composite using Deflection Track

HOW Composite Wall w/ 30mil 2-1/2" Leg MaxTrak® or 30mil 2-1/2" Deep Leg Deflection Track

HOW Composite limiting heights were tested in accordance with AISI S916 and ICC-ES AC86.

The tests were modified from the standards with the tracks fastened to the test fixture such that the wall stiffness included the track deformation.

It is important to note that a wall designed using limiting heights from HOW composite tables must be constructed consistent with notes listed below the HOW Composite limiting heights tables.

Use HOW Composite tables if your wall meets these conditions:

- Maximum deflection gap is 7/8" or less

- Meets the requirements of the most common 1/2" and 3/4" deflection gap

- For use with the following Deflection Tracks:

- 30mil 2-1/2" Leg MaxTrak®

- 30mil 2-1/2" Deep Leg Deflection Track

- Thicker MaxTrak or Deep Leg Deflection Track noted above are allowed but won't increase limiting heights without additional testing

- 5/8" Type X Gypsum board applied full height in the vertical orientation

- (Leaving a 7/8" max. deflection gap and not having the board attached to the top deflection track is allowed)

Head-of-Wall (HOW) Composite Limiting Height Tables

- ProSTUD 25 / 15mil HOW Composite Limiting Heights w/ 30mil 2-1/2" Leg MaxTrak

- ProSTUD 20 / 18mil HOW Composite Limiting Heights w/ 30mil 2-1/2" Leg MaxTrak

- ProSTUD 30mil HOW Composite Limiting Heights w/ 30mil 2-1/2" Leg MaxTrak

- ProSTUD 33mil HOW Composite Limiting Heights w/ 30mil 2-1/2" Leg MaxTrak

- ProSTUD 25 / 15mil HOW Composite Limiting Heights w/ 30mil 2-1/2" Deep Leg Deflection Track

- ProSTUD 20 / 18mil HOW Composite Limiting Heights w/ 30mil 2-1/2" Deep Leg Deflection Track

- ProSTUD 30mil HOW Composite Limiting Heights w/ 30mil 2-1/2" Deep Leg Deflection Track

- ProSTUD 33mil HOW Composite Limiting Heights w/ 30mil 2-1/2" Deep Leg Deflection Track

Need help with selecting the right tables for your Project?

- Submit info to our Technical Support Team to help answer your questions.

FULL Composite Assemblies

Full composite wall w/ 1-1/4" Leg Non-Deflection Track

Full composite limiting height data can be applied to walls where gypsum board is installed on both flanges of the stud for the full height of the wall and to the top and bottom tracks. ProSTUD® full composite data is based on the 2018 International Building Code, and was tested and analyzed in accordance with the most recent version of AISI S916 and ICC-ES AC86.

It is important to note that a wall designed using limiting heights from composite tables must be constructed consistent with the assembly as it was tested per AISI S916 and ICC-ES AC86.

Not to be used with:

- Deflection Tracks

- Resilient Channel

- Sound Clips

- 1/2" Gypsum Board

- Horizontally Installed Board

SFIA Technical Publication

Full Composite Limiting Height Tables

Non-Composite Assemblies

Non-composite conditions are common in all structures. When the gypsum board stops at the ceiling level, but the stud continues to the deck, it is a non-composite condition. Wall framing with Deflection Track/MaxTrak, Resilient Channel (RC) or Sound Clips is a non-composite design since the screws attaching the gypsum board are not directly attached to the framing or top track. While there may be advantages to contacting Technical Services or a Design Professional, many conditions can be covered by limiting heights tables shown below. When in doubt, call our complimentary Technical Services Hotline at 888-437-3244.

Distance of unbraced length (Lu) can be found in ProSTUD® Physical and Structural Properties.

Non-Composite Limiting Height Tables

ProSTUD Non-Composite Limiting Heights - FULLY BRACED

ProSTUD Non-Composite Limiting Heights - BRACED AT 48" O.C.

Ceiling Span Tables

Interior ceilings are often supported by ProSTUD® framing. The design criteria varies greatly based on the weight of the ceiling, bracing, and support points.

Chase Walls or Furred Walls

Chase & furred walls are common, but the conditions vary greatly depending on the building requirements. While non-composite tables may be used conservatively, when in doubt, contact our Technical Services Hotline at 888-437-3244 for chase wall designs.

See: ProSTUD Chase Wall Sound Rated Assemblies

ProSTUD® UL® Fire-Rated information

Meeting limiting height requirements are only part of the strengths of ProSTUD Drywall Framing. When it comes to meeting fire-rated systems, ProSTUD is UL approved for the most common UL design assemblies. All fire-rated assemblies comply to UL 263 test standards.

ProSTUD UL fire-rated approvals:

ProSTUD® Sound Rated Assemblies

ProSTUD has exceptional sound performance in over 75 tested sound assemblies.

Sound Testing was conducted by:

Western Electro - Acoustic Laboratory

ProSTUD STC Ratings sorted by assemblies:

Testing Agencies & Certifications

Independent Product Testing & Certifications

ProSTUD® is Pro Tested! We enlisted the help of the top testing and analysis agencies in the industry to develop ProSTUD. Below is a list of the professional organizations and third party reports for ProSTUD.

Fire Testing

Sound Testing

Structural Analysis (West Coast Products Only)

Easy installation of wiring, plumbing and bridging.

ProSTUDs are pre-punched with punchouts at regular intervals—specifically designed to allow for rapid installation of pipes, electrical conduit and wall bridging.

East Coast / Central punch spacing:

Center of punchouts are 12" from lead end, then 48" o.c.

West Coast punch spacing:

Center of punchouts are 24" from lead end, then 24" o.c.

Center of tail end punchout not less than 12" from end of stud.

Caution must be exercised when installing studs so knockouts align for bridging. Based on stud length, the distance the knockout falls from the tail end of the stud may not be the same from the lead end. To align punchouts, make sure to use the same end in the same direction consistently.

If lateral bracing is required for head-of-wall deflection track and a punchout is not spaced 12" from the top of stud, use strapping and blocking in lieu of CRC or Spazzer Bar lateral bridging.

If custom punchout patterns are required, contact ClarkDietrich Sales or local plant for requests.

ProSTUD® Allowable screw design values (lb.)

Non-Structural (ProSTUD) - Screw Allowable Loads

- Contact ClarkDietrich Technical Services at 888-437-3244 for questions about Screw Connections into ProSTUD Drywall Framing.

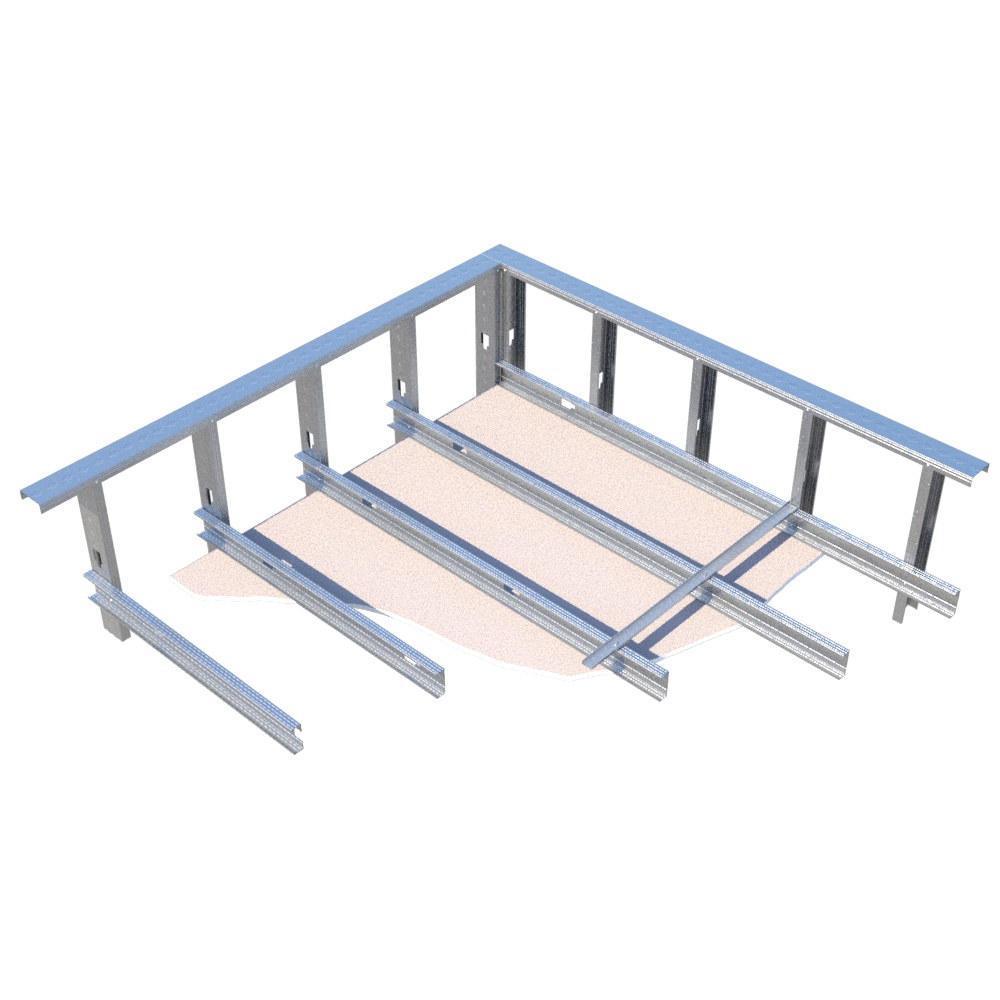

ProTRAK® Deep Leg Deflection Track Systems

Head-of-wall vertical deep leg deflection track systems are required to allow the top of the wall stud to float within the top track legs. This connection allows for vertical live load movement of the primary structure without transferring axial loads to the interior drywall studs. A gap (determined by the Engineer of Record) is required between the top of the wall stud and the deflection track.

Wall framing with Deflection Track is typically non-composite design since the screws attaching the gypsum board are not directly attached to the top track.

(NEW) Head-of-Wall Composite tables using Deflection Track w/ 30mil 2-1/2" Leg MaxTrak® or 30mil 2-1/2" Deep Leg Deflection Track. See ProSTUD / Technical Data for more information.

ProSTUD Drywall Framing studs can be used with multiple Deep Leg Track Systems:

The below link shows more detail on each system:

ProTRAK Deep Leg Deflection Track Systems

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about deflection track systems.

Code Approvals & Performance Standards

- AISI S100-16 (2020) w/S2-20 North American Specification for the Design of Cold-Formed Steel Structural Members

- AISI S220-20 North American Standard for Cold-Formed Steel Framing - Nonstructural Members

- (Compliant to ASTM C645, but IBC replaced with AISI S220 in IBC 2015)

- Section A3 Material - Chemical & mechanical requirements (Referencing ASTM A1003/A1003M)

- Section A4 Corrosion Protection (Referencing ASTM A653/A653M)

- Section A5 Products - Thickness, shapes, tolerances, identification

- Section C Installation - (Referencing ASTM C754)

- AISI S202-20 Code of Standard Practice for Cold-Formed Steel Structural Framing

- Section F3 Delivery, Handling and Storage of Materials

- UL File Number CIKV.R26512 ProSTUD fire rated assemblies

- UL File Number CIKV.R26512 ProTRAK fire rated assemblies

- ASTM E72 Standard Test Methods of Conducting Strength Tests of Panels for Building Construction

- ASTM E90 Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements

- ASTM E119 Standard Test Methods for Fire Tests of Building Construction and Materials

- IBC 2024 International Building Code

- Intertek CCRR-0207 Non-Structural Metal Framing

- UL Designs 263 "Fire Tests of Building Construction and Materials"

- SDS For ASTM A1003 Steel Framing Products For Interior Framing, Exterior Framing and Clips/Accessories

Smart Edge™ Technology

An Enhancement For Producing Easier-To-Handle Steel That Reduces The Risk Of Cuts And Scrapes.

Smart Edge is a proprietary safety feature now standard with ClarkDietrich’s industry-leading ProSTUD® Drywall Framing System. We have reworked the edge of the return lips of the studs, and the edge of the leg of the runner tracks, making them smoother and more rounded. The result is an easier-to handle product that reduces the risk of cuts and scrapes for installers, as well as for other trades who may come in contact with the framing.

Downloads:

DiamondPlus® Coating

Prostud® with clarkdietrich DiamondPlus® Coating

While standard G40 studs are accepted by many as the industry standard for interior steel framing, ClarkDietrich also offers ProSTUD with DiamondPlus coating—the next generation of high-performance, code-compliant steel framing systems.

Downloads:

- DiamondPlus vs G40: Salt Spray Comparison Sheet

- DiamondPlus Brochure

- Equivalent Coatings White Paper

- DiamondPlus Infographic - Steps we take to create ProSTUD with DiamondPlus

What is an EQ Drywall Stud?

Life Safety - System Performance - Connections

Gauge equivalent drywall framing must meet the minimum performance requirements of conventional drywall framing as defined by the Steel Framing Industry Association (SFIA). The industry’s “EQ” product of choice, ProSTUD®, employs roll-forming and steel-making technology, exceeding the performance of conventional drywall framing for allowable moment and screw connection strength.

When comparing drywall framing systems, it is important to keep in mind Life Safety, System Performance and Connections. The ProSTUD Drywall Framing System provides peace of mind for all three important functions by providing the right selection of products and product data for every application.

Downloads:

Product Substitution Forms

To simplify the Product Substitution Request process when ClarkDietrich’s Products are not listed in the Architectural Specification, select one of the CSI Forms in our ClarkDietrich Substitution Request Forms Page to help streamline the procedure.

For creating product submittals to attach to these forms use ClarkDietrich's SubmittalPro Product Submittal System.

- For submitting product samples to the Architect call (800) 543-7140 and request ClarkDietrich’s product samples.

Architectural Specifications

Specifying ProSTUD® & ProTRAK®

- ClarkDietrich's MasterSpec Full Length Specifications with ProSTUD can be found by clicking here.

- For a complimentary specification review, contact our Architectural Spec Review Team at 330-978-3157 or e-mail us at: info@clarkdietrich.com.

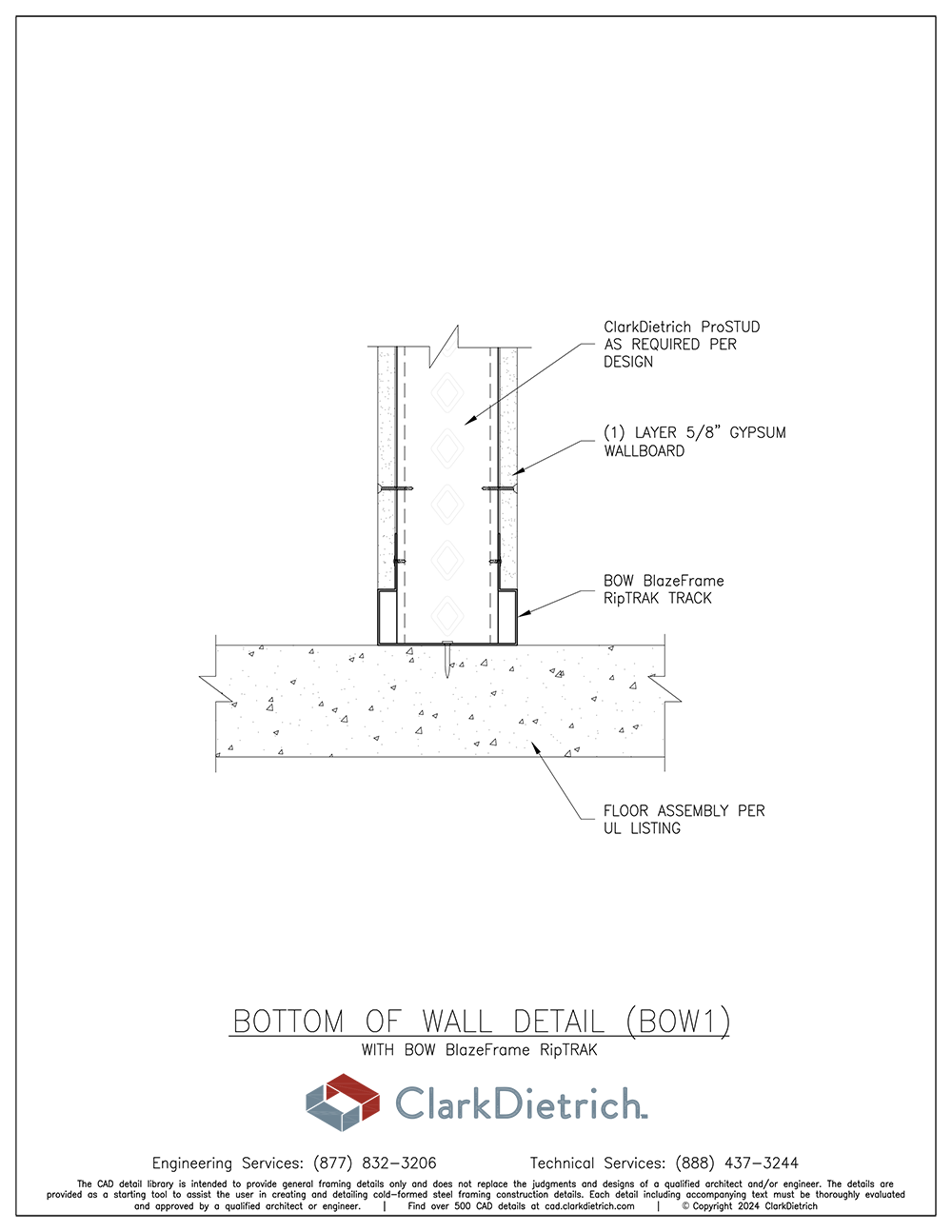

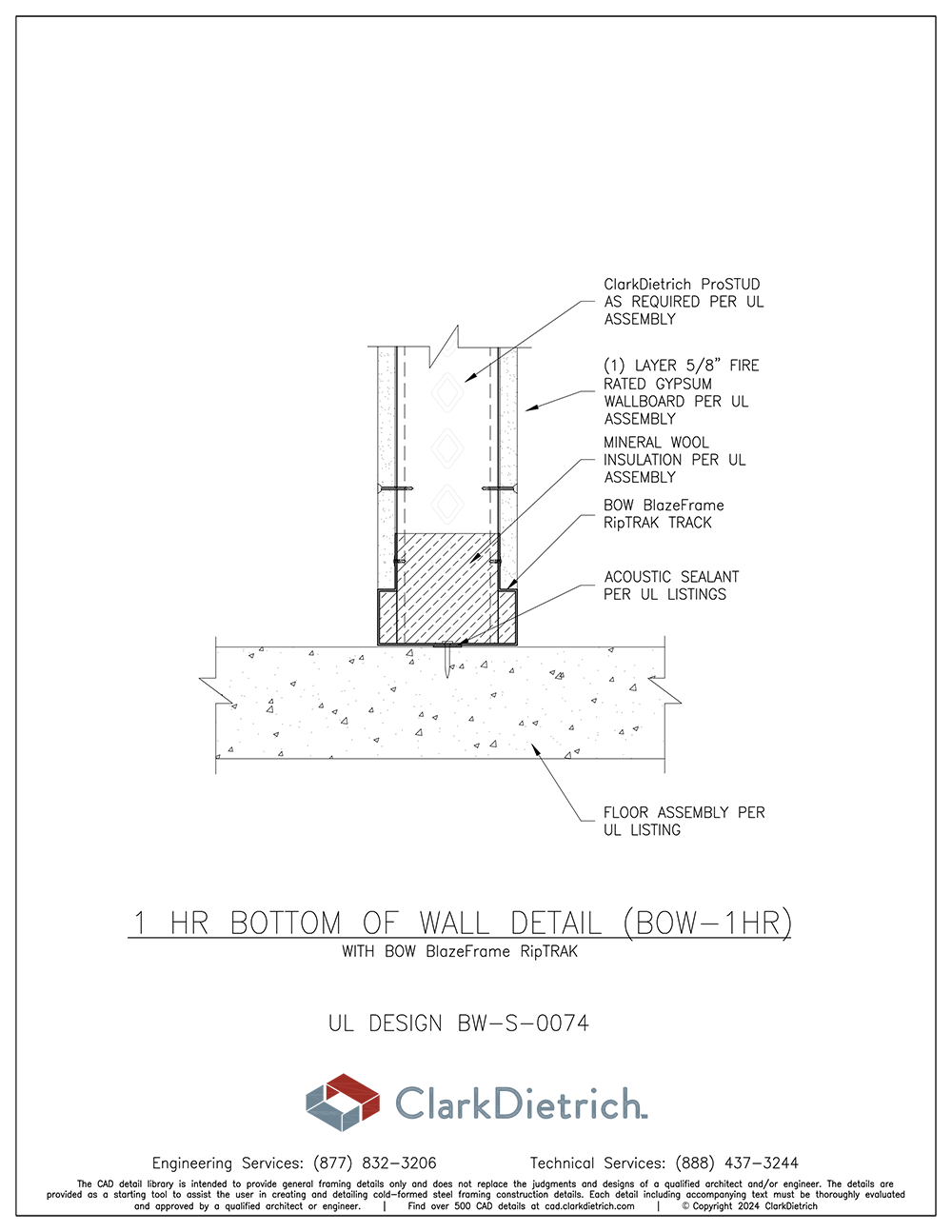

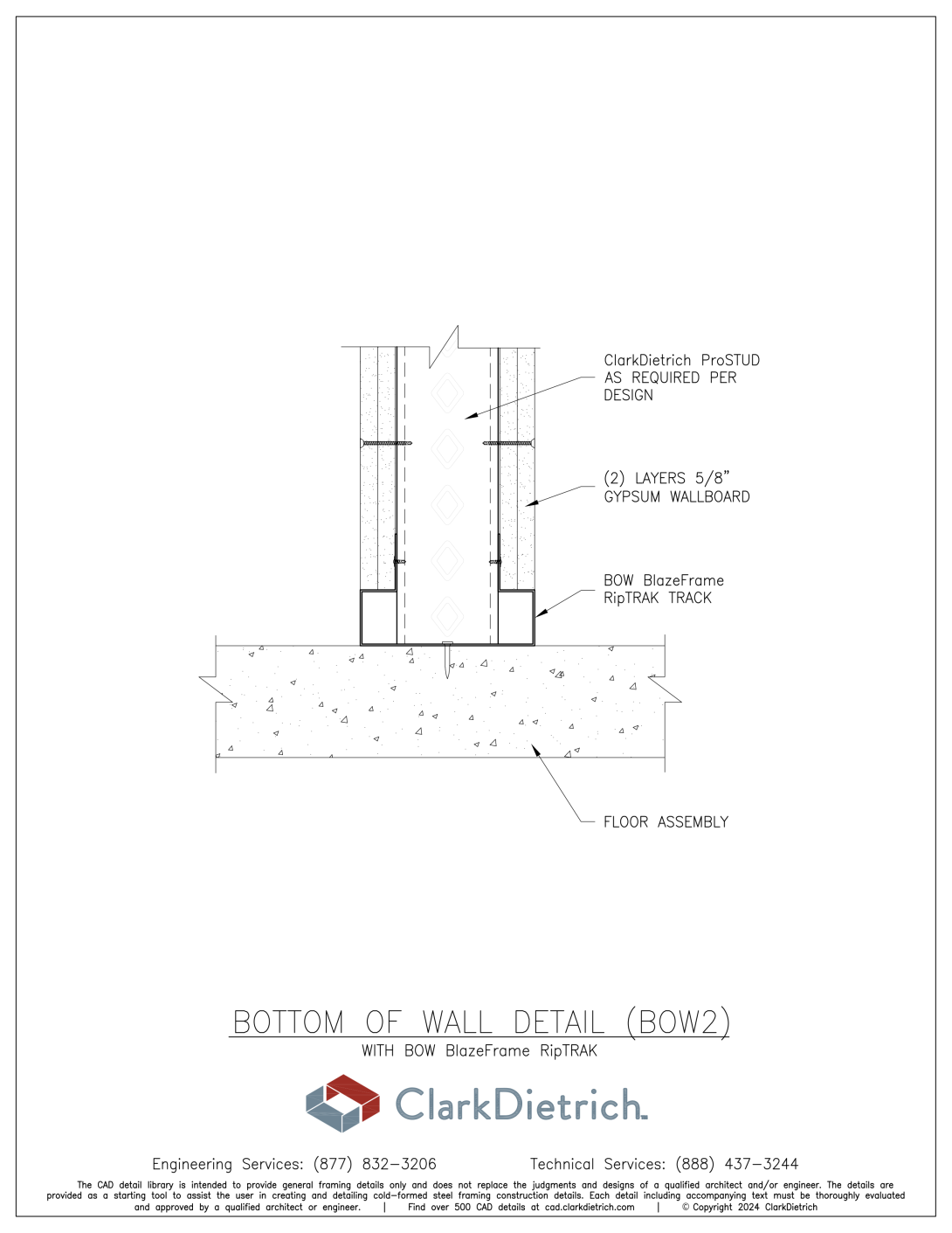

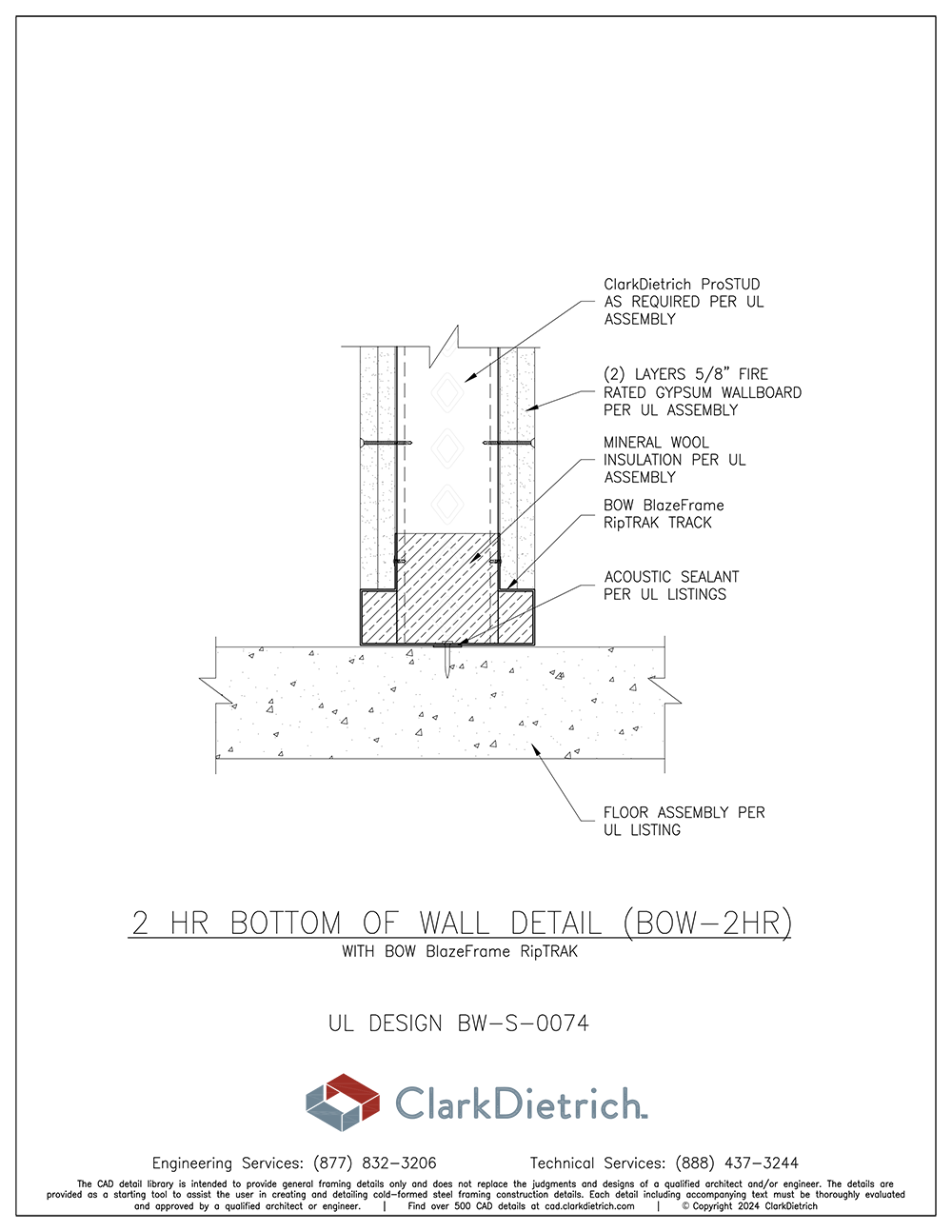

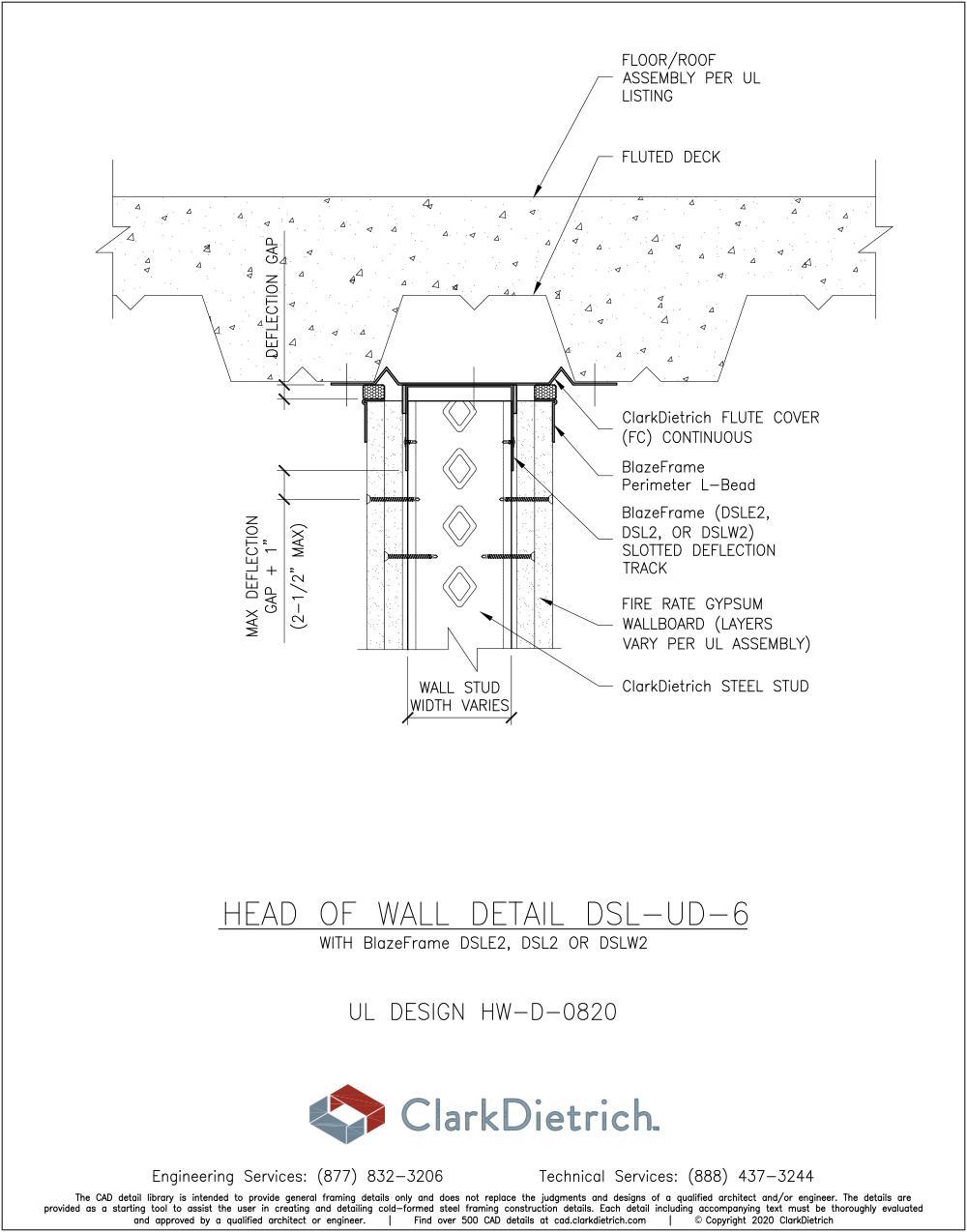

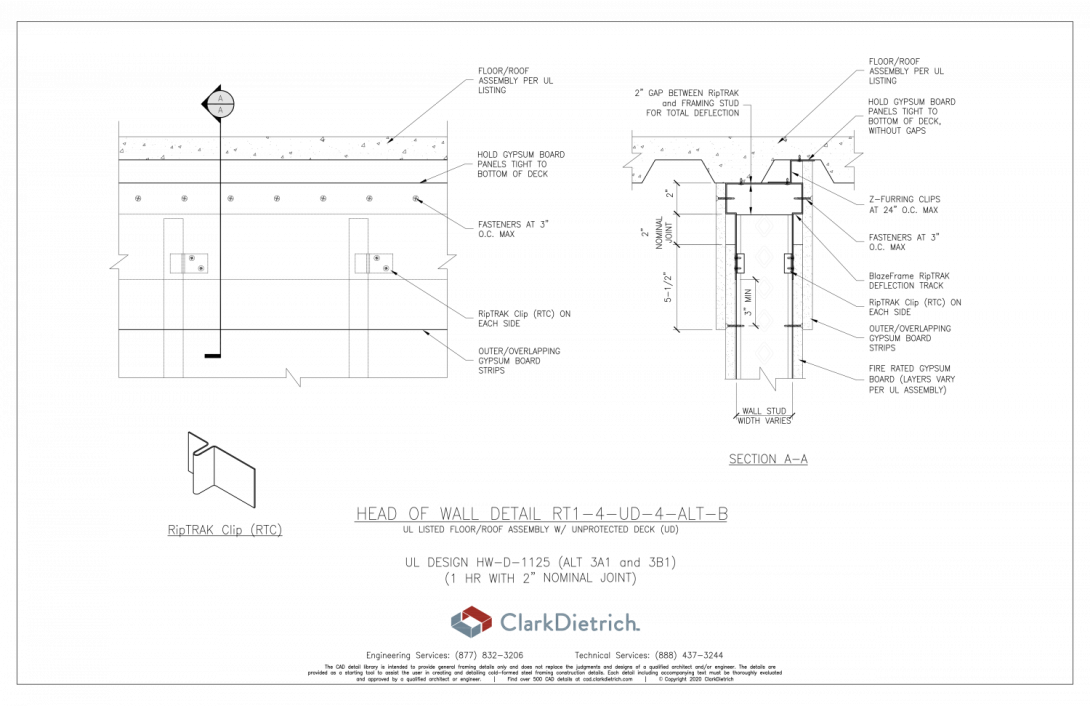

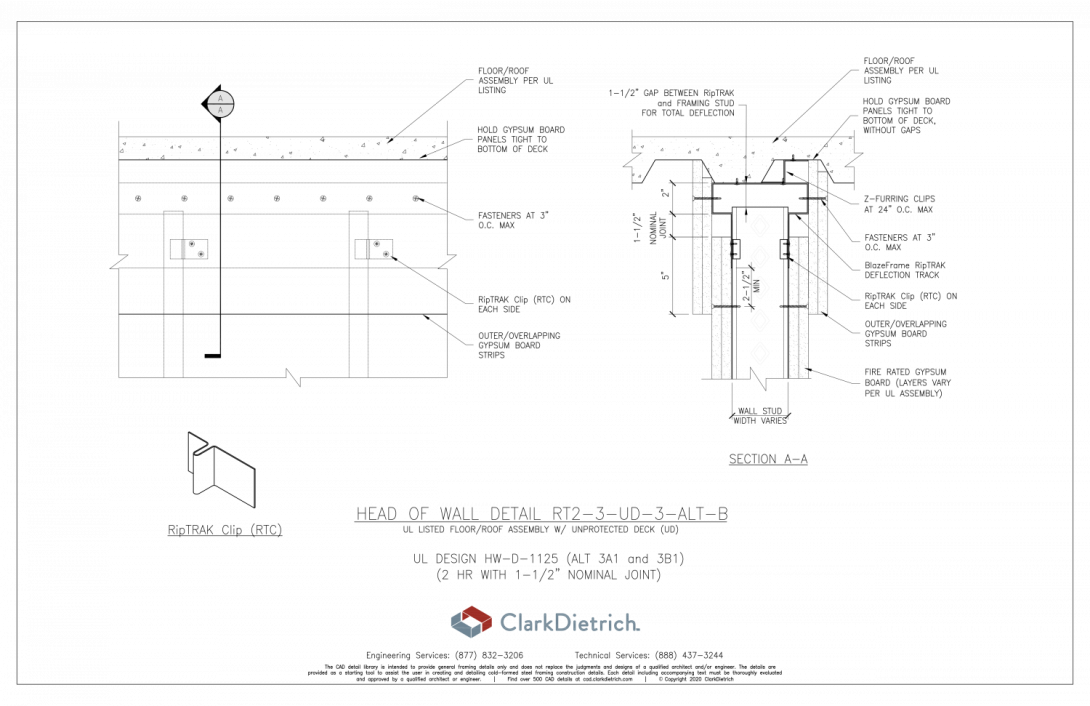

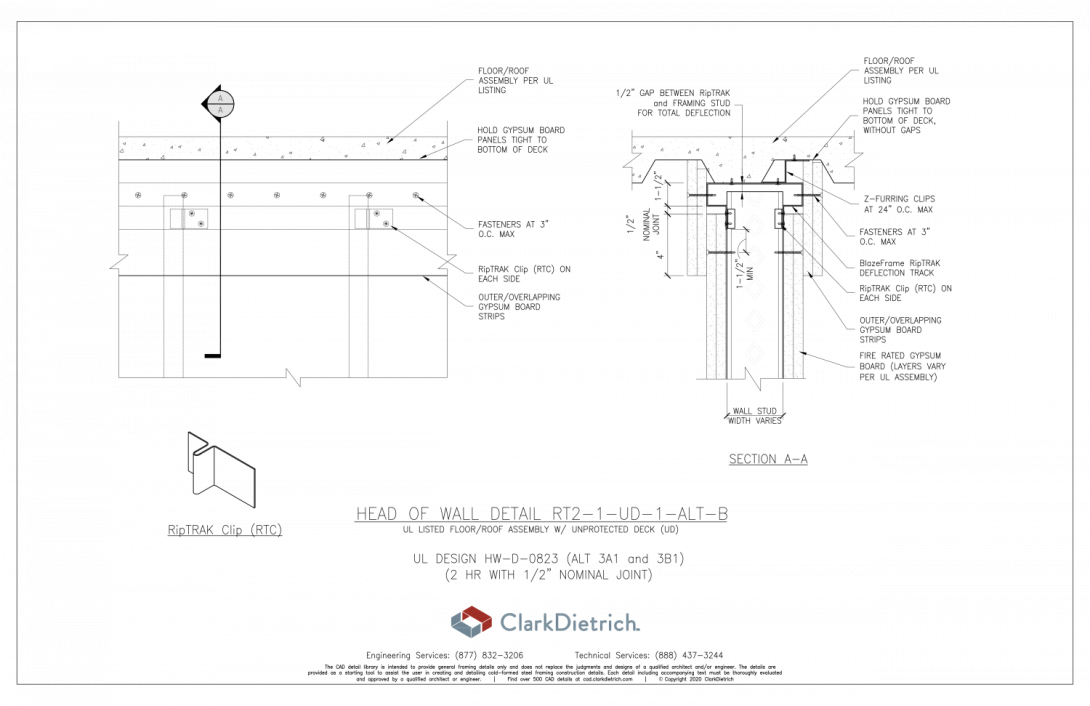

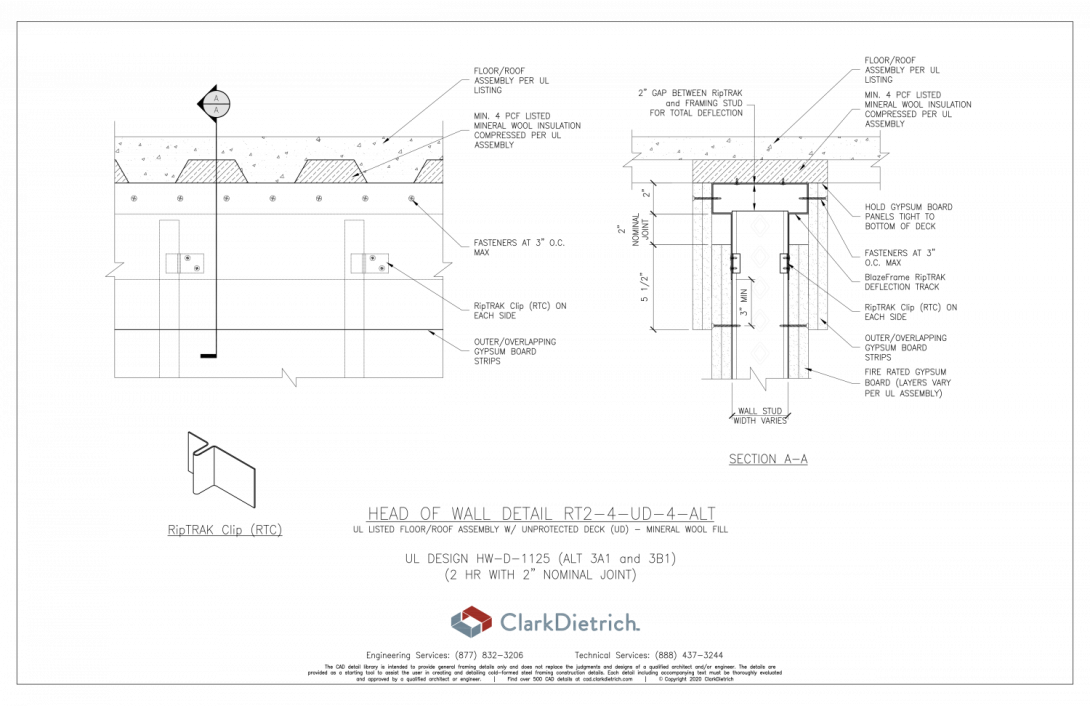

CAD Details

Note: to view all of ClarkDietrich's CAD details, visit the CAD Details Library.

ClarkDietrich SubmittalPro®

The Fastest way to find product information

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

Most common ProSTUD submittals can be found below:

| Size / Thickness | ProSTUD | ProTRAK |

|---|---|---|

| 3-5/8" Pro25 (15mil 50ksi) | 362PDS125-15 | 362PDT125-15 |

| 3-5/8" Pro20 (18mil 70ksi) | 362PDS125-18 | 362PDT125-18 |

| 3-5/8" Pro 30mil 33ksi | 362PDS125-30 | 362PDT125-30 |

| 3-5/8" Pro 33mil 33ksi | 362PDS125-33 | 362PDT125-33 |

| Find all profiles in SubmittalPro® Product Submittal System | ||

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about creating product submittals or using SubmittalPro.