Performance that stands up to deflection

For superior head-of-wall vertical deflection, and the added benefit of horizontal drift movement, ClarkDietrich has your answer.

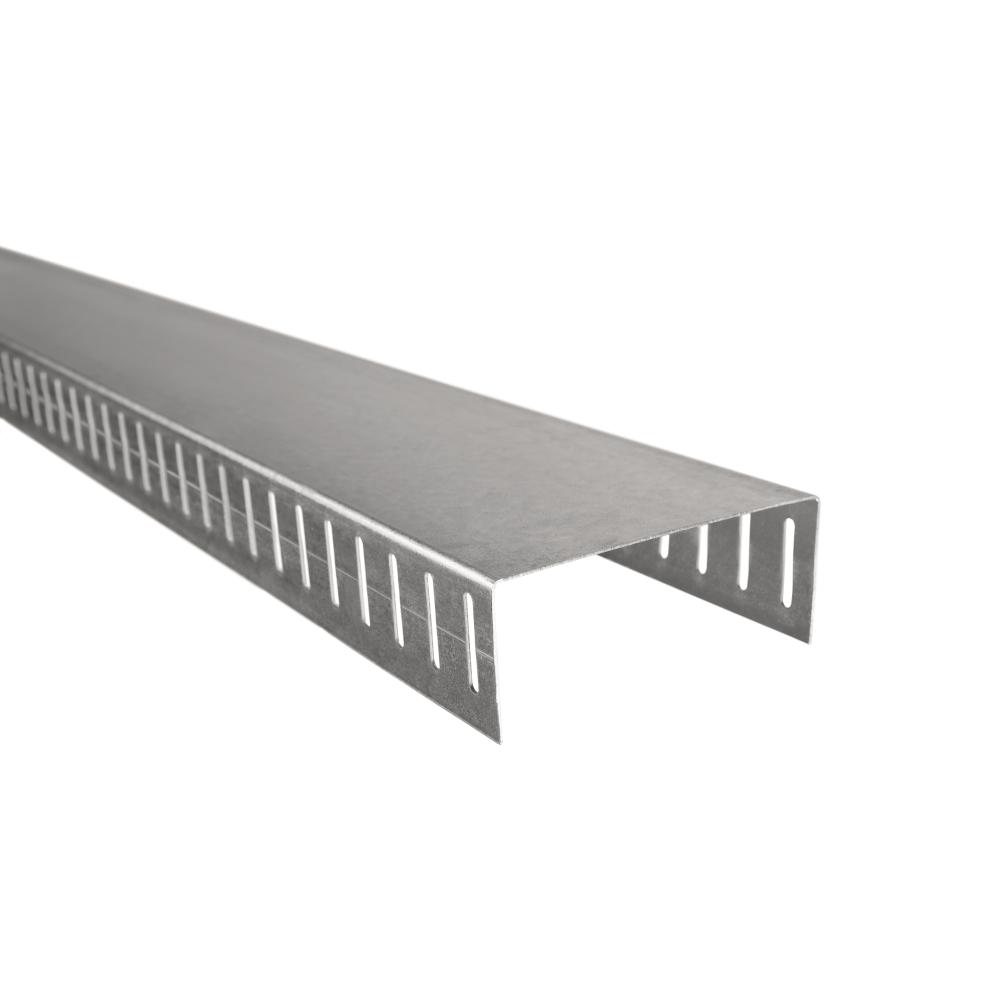

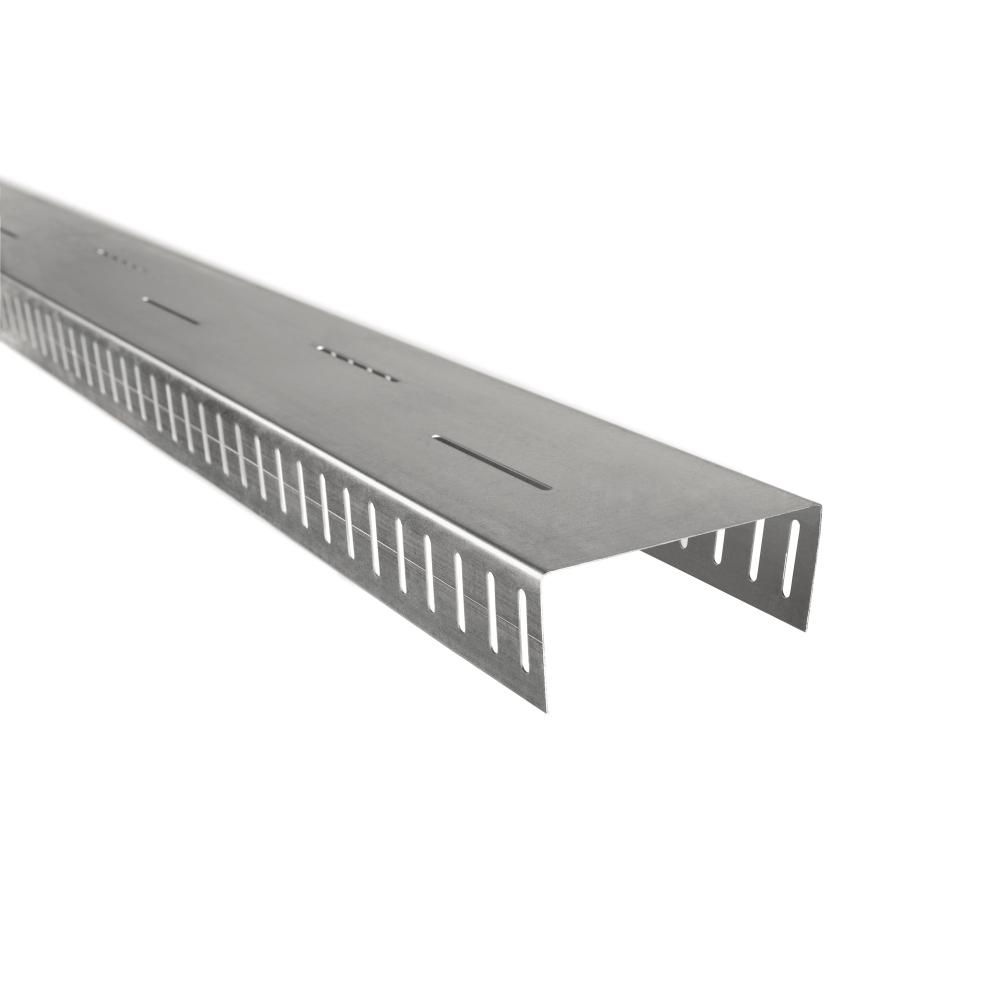

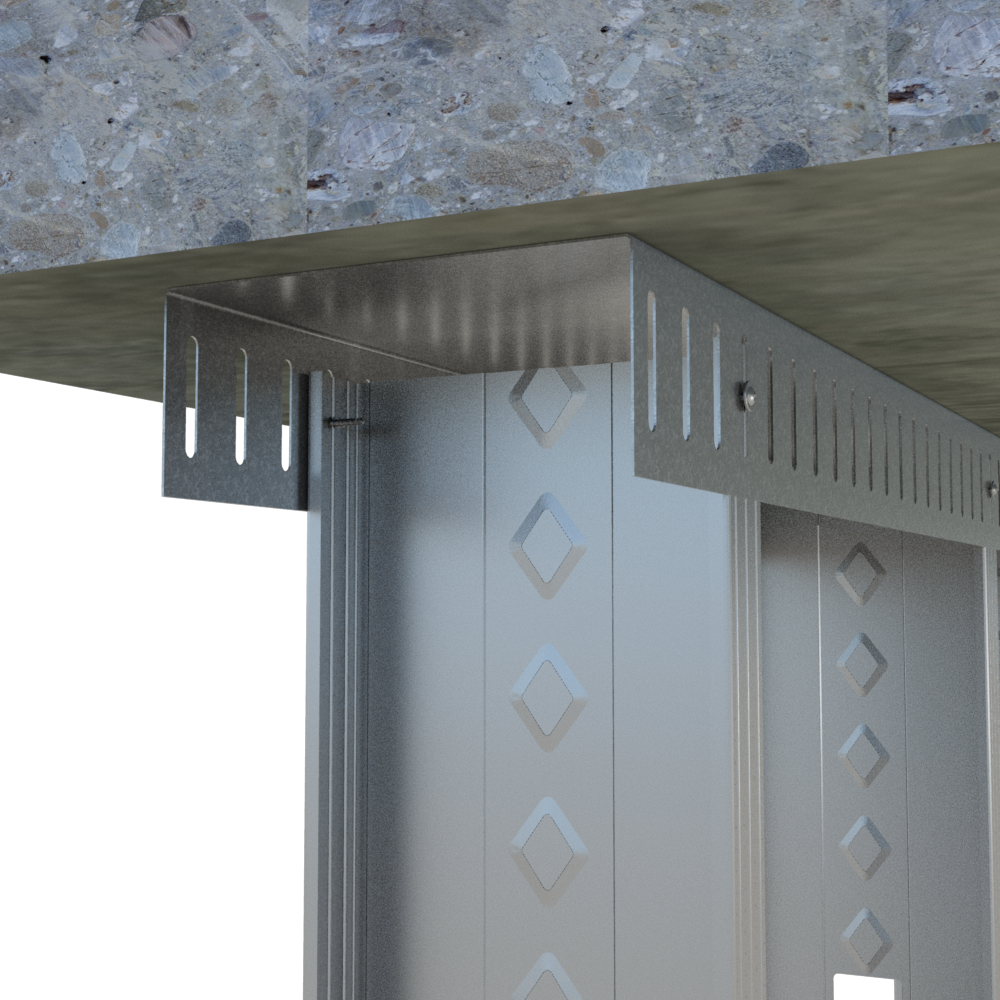

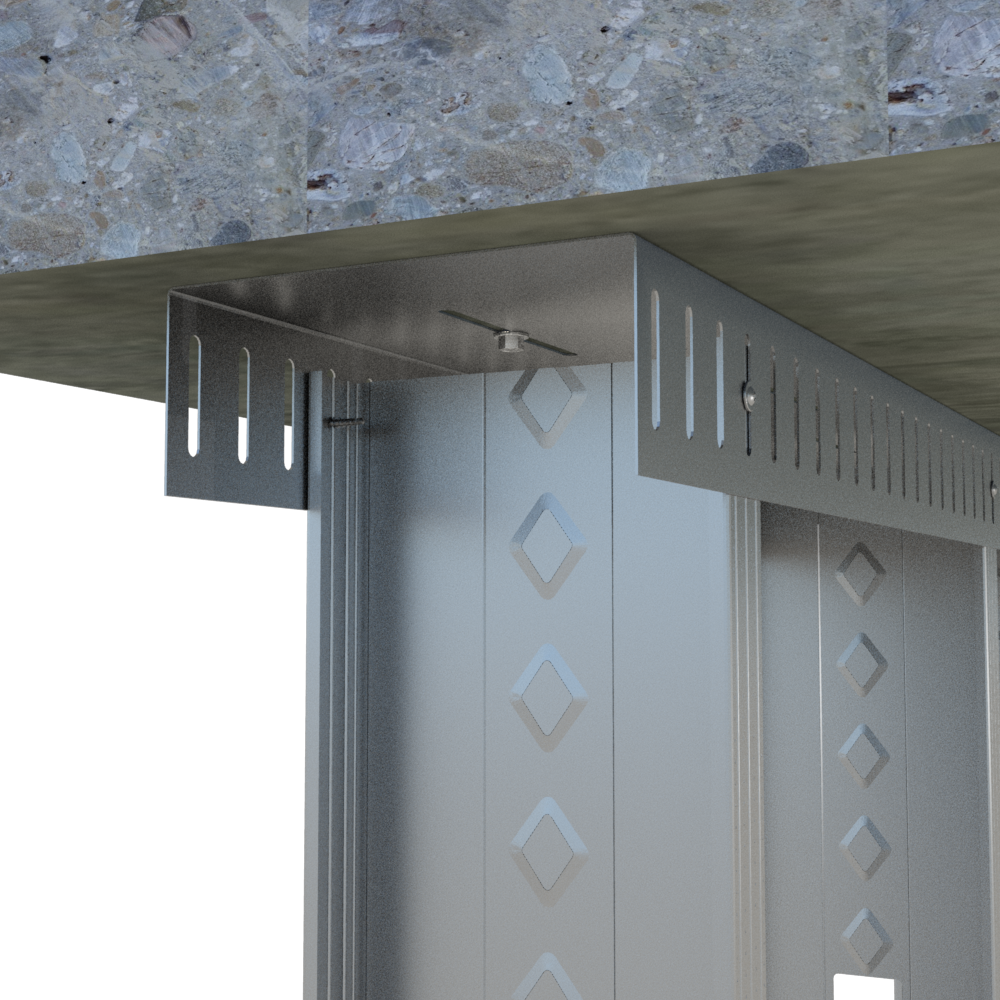

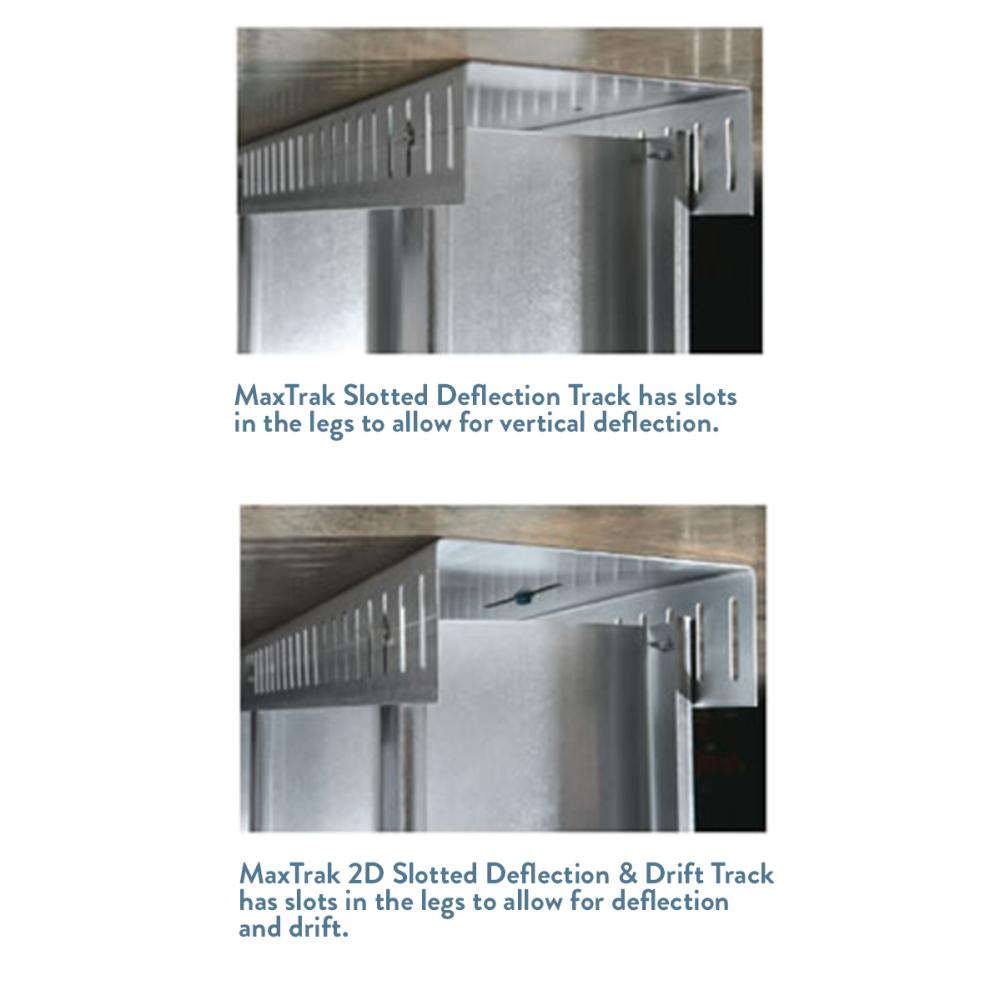

For superior head-of-wall vertical deflection, and the added benefit of horizontal drift movement, ClarkDietrich introduces two solutions—MaxTrak® Slotted Deflection Track and MaxTrak® 2D Slotted Deflection & Drift Track. The MaxTrak System allows the top of the wall stud to float within the track legs. This connection allows for vertical live load movement of the primary structure without transferring axial loads to the wall studs. In addition, MaxTrak 2D also has slots in the web to allow for horizontal drift when required by seismic designs.

Construction Advantages:

- Provides positive attachment to wall framing for overall wall strength with no additional components

- MaxTRAK Non-Structural Systems are available with 2-1/2" legs

- MaxTRAK Structural Systems are available in two leg lengths: 2-1/2" or 3" legs

- 2-1/2" Leg MaxTRAK has 1-1/2" long slots with a total allowable vertical (deflection) movement of 1-1/2" (3/4"±)

- 3" Leg MaxTRAK has 2" long slots with a total allowable vertical (deflection) movement of 2" (1"±)

- Total allowable horizontal (drift) movement of 4" (2"±) (MaxTrak 2D only)

- One-piece system reduces the cost of materials and labor

- Easy installation reduces labor costs

- Fire-rated system integrates with a variety of UL® head-of-wall fire stop systems

- MaxTrak 2-1/2" Leg system has code report Intertek CCRR-0205

- Can be used for both interior non-load bearing walls and exterior curtain wall systems

- Embossed guideline at center of vertical deflection slot helps installers correctly position fasteners accurately and quickly

Design Advantages:

ClarkDietrich Engineering Service & Technical Services are Here to Support You.

- MakTrax and MaxTrak 2D 2-1/2" Leg is Intertek code certified for lateral and horizontal loads.

- Refer to MaxTrak product submittals for allowable lateral load information.

Load Tables

- For load tables, see Product Submittal Sheets

MaxTrak™ UL® fire-rated information:

Meeting deflection and drift requirements are only part of the strengths

of MaxTrak. When it comes to meeting fire-rated systems, MaxTrak is UL® approved for the most common UL® design assemblies and a variety of head-of-wall fire stop systems. All fire-rated assemblies comply to UL 2079 test standards.

MaxTrak and MaxTrak 2D UL® fire-rated approvals:

- UL Approved Systems - Listing Partner and Design Number

- UL-2079 Test Standard Compliant

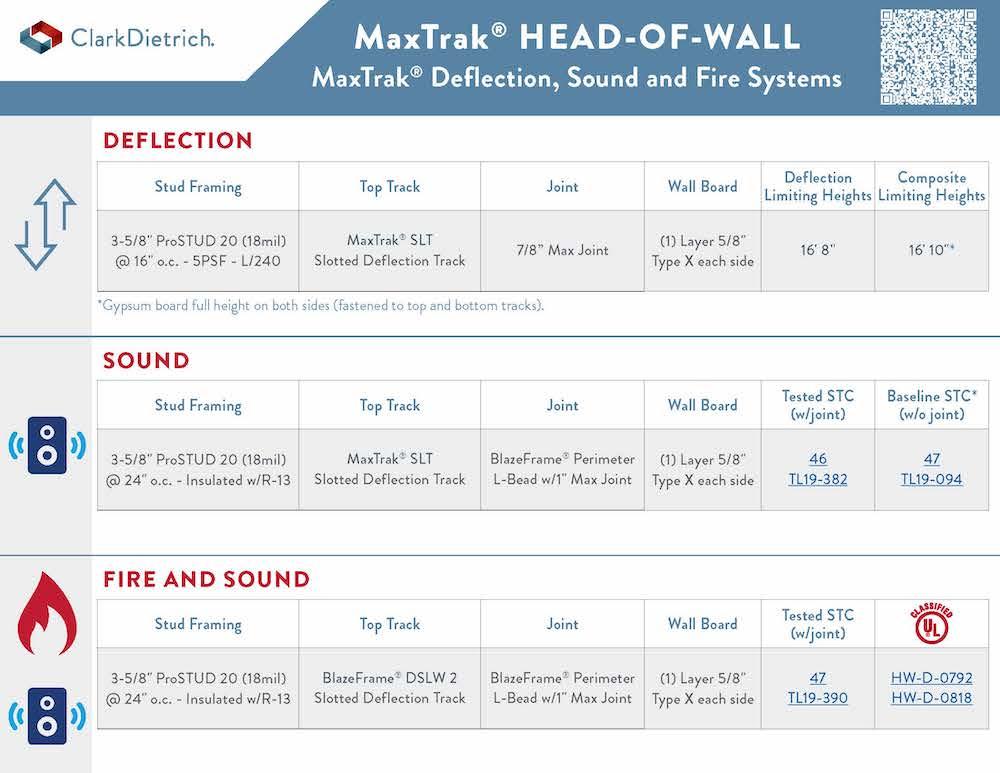

MaxTrak™ deflection, sound and fire:

Code Approvals & Performance Standards

- AISI S100-16 (2020) w/S2-20 North American Specification for the Design of Cold-Formed Steel Structural Members

- AISI S220-20 North American Standard for Cold-Formed Steel Framing - Nonstructural Members

- (Compliant to ASTM C645, but IBC replaced with AISI S220 in IBC 2015)

- Section A3 Material - Chemical & mechanical requirements (Referencing ASTM A1003/A1003M)

- Section A4 Corrosion Protection (Referencing ASTM A653/A653M)

- AISI S240-20 North American Standard for Cold-Formed Steel Structural Framing

- (Compliant to ASTM C955, but IBC replaced with AISI S200 in IBC 2015, AISI S240 in IBC 2018)

- Section A3 Material - Chemical & mechanical requirements (Referencing ASTM A1003/A1003M)

- Section A4 Corrosion Protection (Referencing ASTM A653/A653M)

- Intertek CCRR-0205 MaxTrak - Code Compliance Research Report

- For Structural Stud Framing (33mil and thicker)

- Intertek CCRR-0207 Non-Structural Metal Framing

- For Non-Structural Stud Framing (30 mil and thinner)

- UL Designs 2079 Fifth Edition Tests for Fire Resistance of Building Joint Systems

- UL File Number XHLI.R26034 CD MaxTRAK types SLT and SLT-H fire rated assemblies

- SDS For ASTM A1003 Steel Framing Products For Interior Framing, Exterior Framing and Clips/Accessories

Product Substitution Forms

To simplify the Product Substitution Request process when ClarkDietrich’s Products are not listed in the Architectural Specification, select one of the CSI Forms in our ClarkDietrich Substitution Request Forms Page to help streamline the procedure.

For creating product submittals to attach to these forms use ClarkDietrich's SubmittalPro Product Submittal System.

-

For submitting product samples to the Architect call (800) 543-7140 and request ClarkDietrich’s product samples.

ClarkDietrich Gold Seal™ Engineering Service

ClarkDietrich Engineering Service offers a complete shop drawing package using the MaxTrak and MaxTrak 2D framing systems to simplifying the submittal process.

Contact ClarkDietrich Engineering Service toll free at 1-877-832-3206.

CAD Details

Note: to view all of ClarkDietrich's CAD details, visit the CAD Details Library.

Product submittal Sheets

Click the below Product Code to view Submittal/Tech Datasheet.

| Product Code | Description |

|---|---|

| MaxTrak 2-1/2" Leg Structural | MaxTrak and MaxTrak 2D Structural Slotted Deflection and Drift Track |

| MaxTrak 3" Leg Structural | |

| MaxTrak 2D 2-1/2" Leg Structural | |

| MaxTrak 2D 3" Leg Structural | |

| MaxTrak 2-1/2" Leg Non-Structural | MaxTrak and MaxTrak 2D Non-Structural Slotted Deflection and Drift Track |

| MaxTrak 2D 2-1/2" Leg Non-Structural |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about creating product submittals or using SubmittalPro.