Framed Rainscreen and/or Finishing rainscreen assemblies

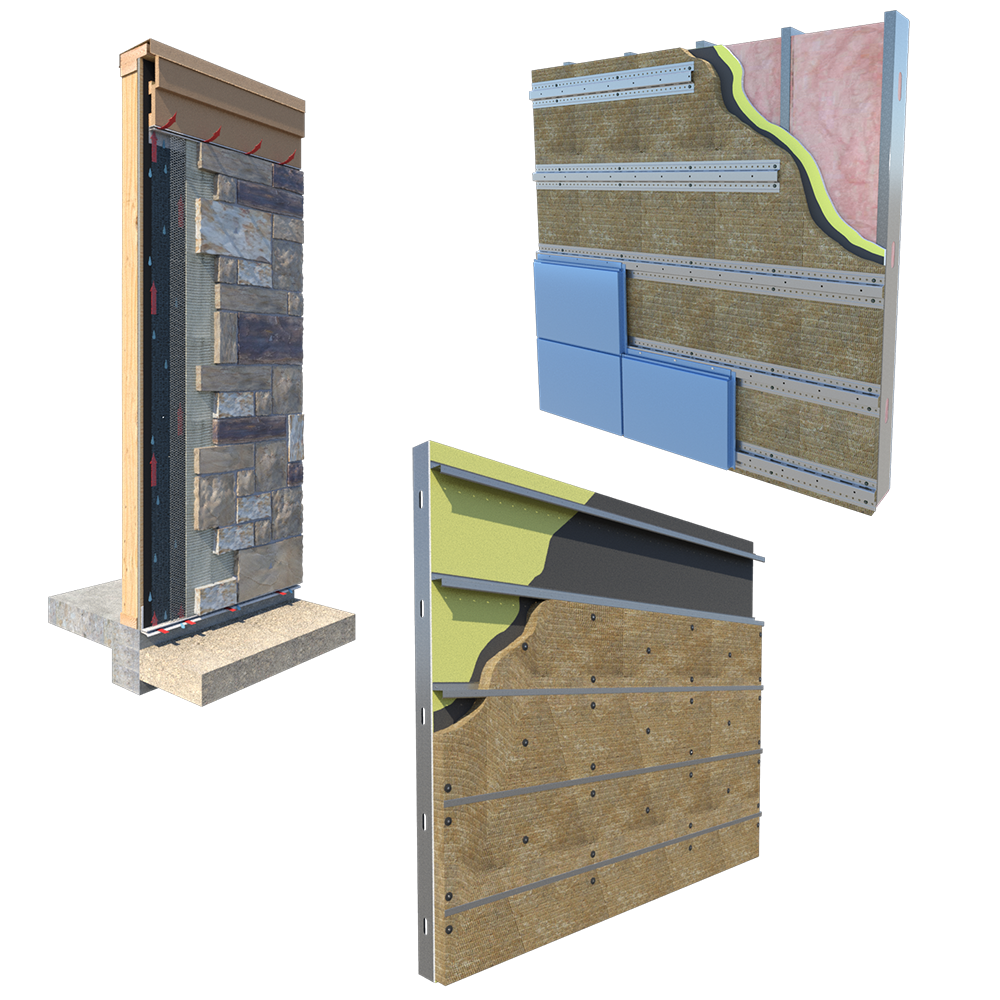

What is a Rainscreen?

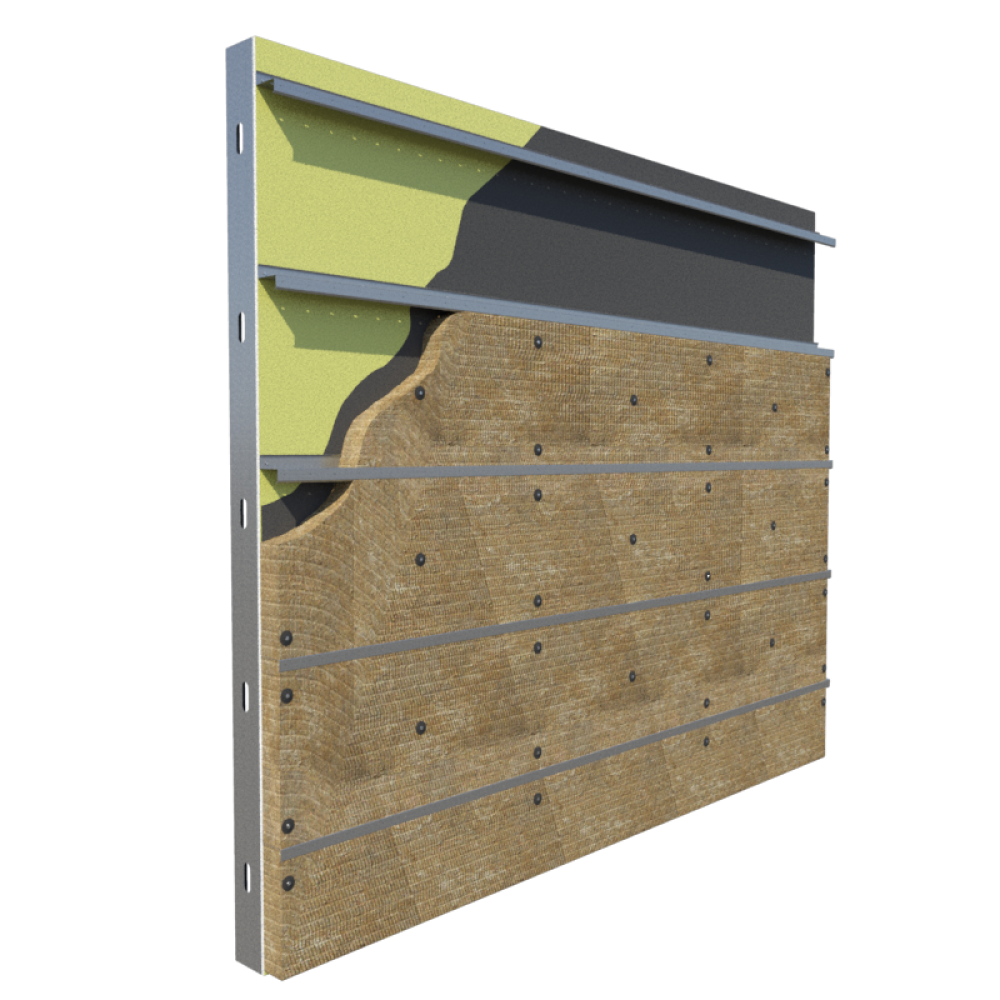

A rainscreen is an exterior wall detail where the siding (wall cladding) stands off from the moisture-resistant surface of an air/water barrier applied to the sheathing to create a capillary break and to allow drainage and evaporation. The ventilated air cavity created by the stand-off can be achieved through framing and/or finishing systems. ClarkDietrich offers rainscreen systems for framing applications or finishing systems.

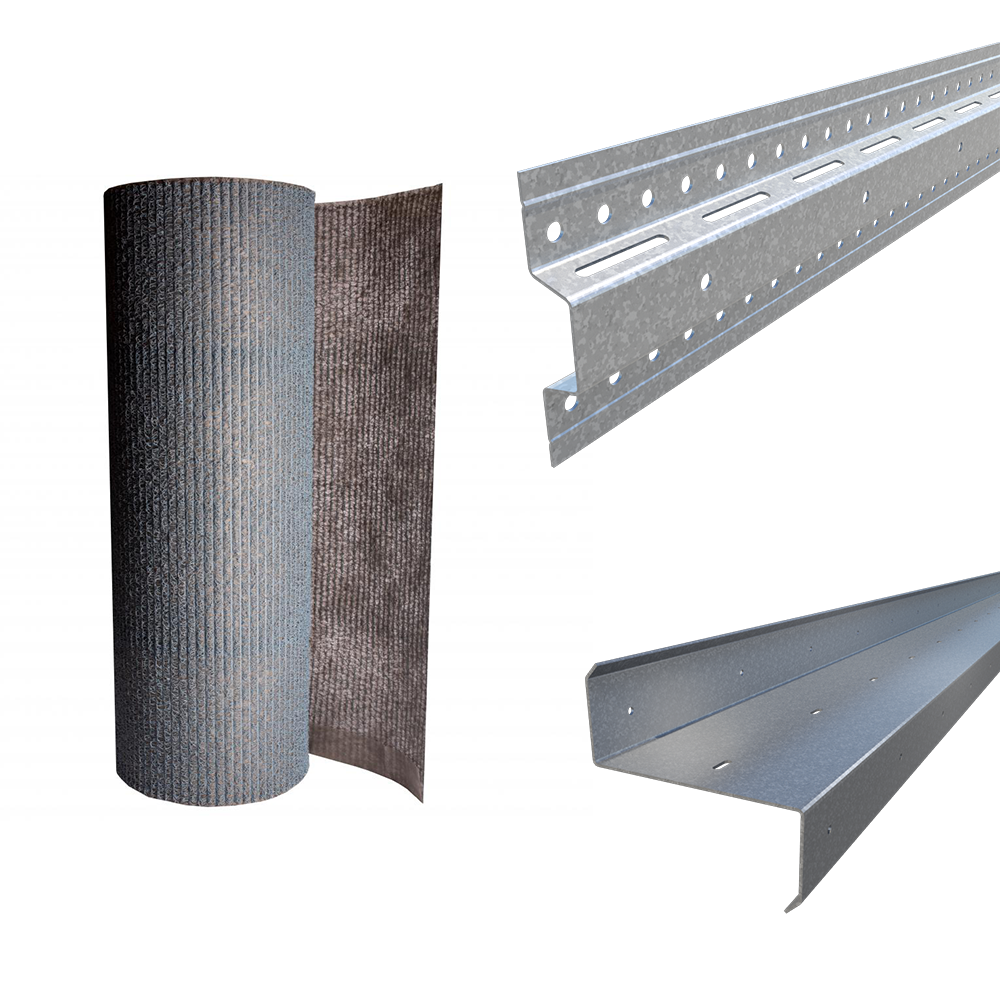

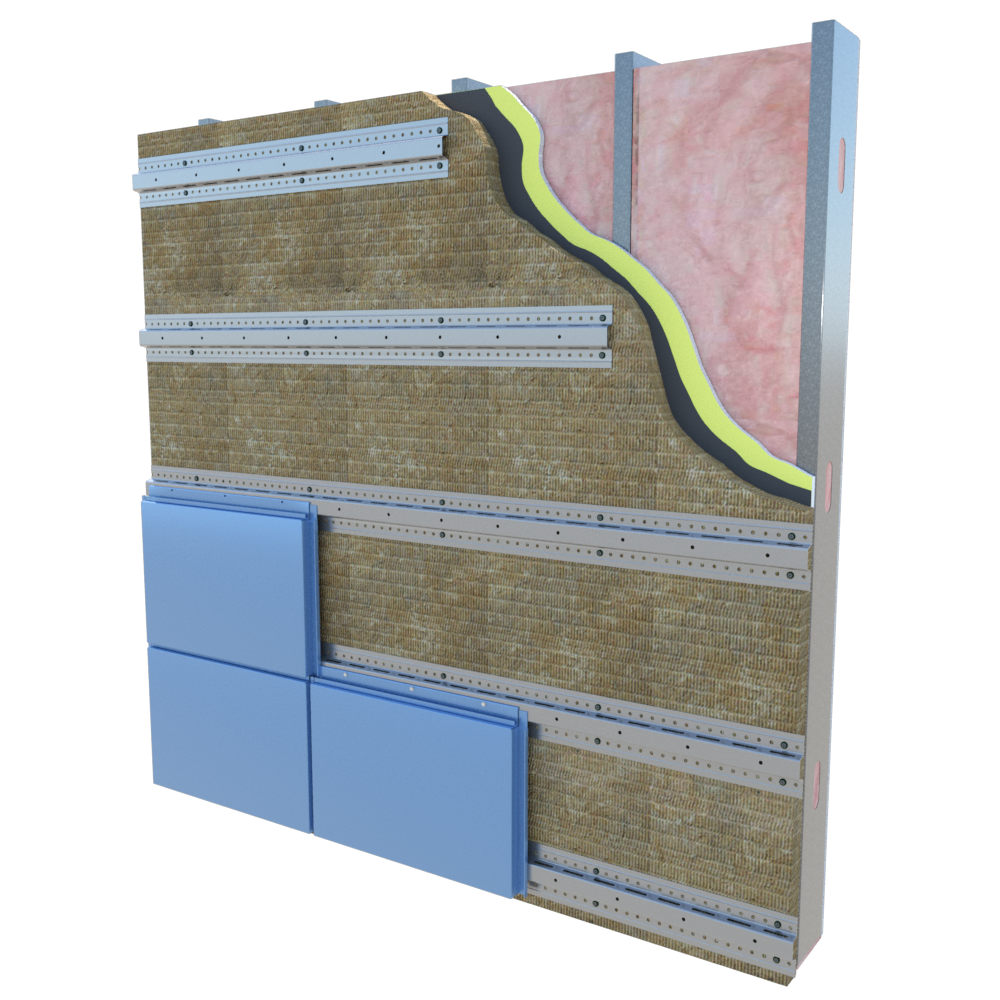

ProChannel Ci TM

ProChannel Ci Cladding Support with Grip-Deck TubeSeal® technology is a thermally and structurally efficient exterior rainscreen wall cladding system utilizing the self-sealing Grip-Deck TubeSeal® fastening system from TruFast Walls. The design is intended to minimize penetrations through the insulation layer and hold an exterior rainscreen cladding in place. This system can be installed with the hat channel running horizontally.

Key Features

- Creates a 7/8" vented rainscreen air cavity

- Standard 12'-0" length

- Thermal performance and load capacity tables available

- Stocked in 54 mils (16ga) galvanized CP90 steel.

- 1-1/2” wide flanges for easy screw attachment.

- Prepunched holes in flange at 1" o.c. for a wide variety of screw spacings.

- Slotted holes moisture weeping and air movement

Commonly used behind:

- Cladding facades

click here For more information

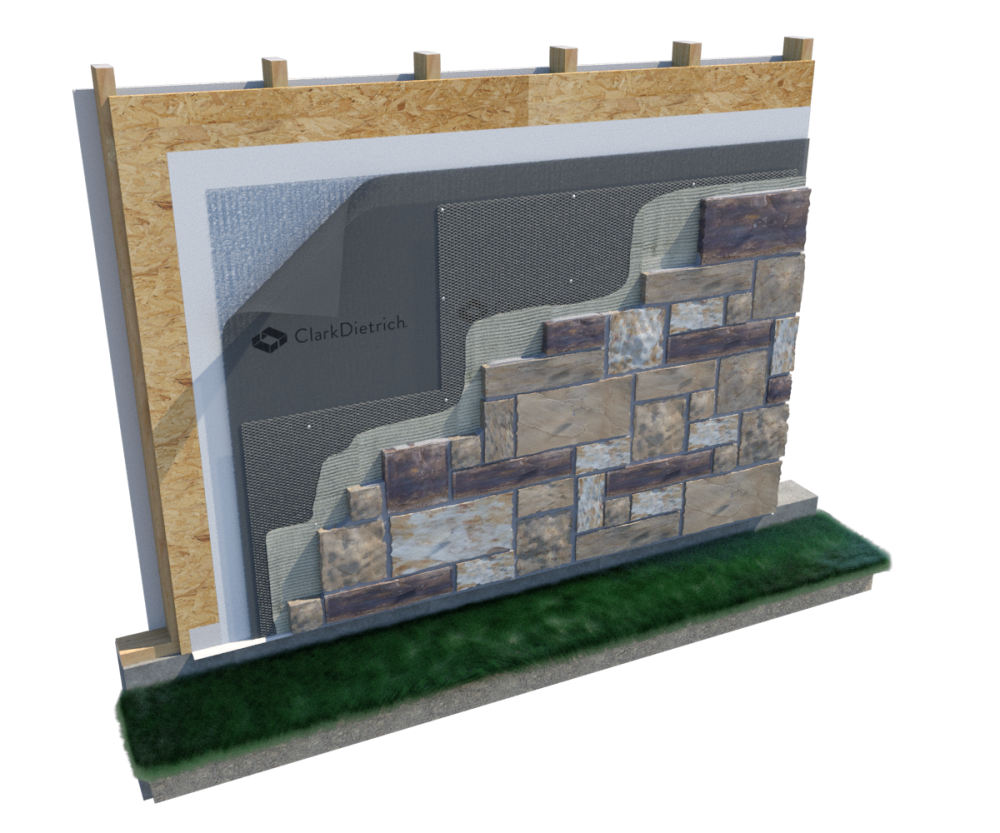

E-Screen rainscreen Drainage Mat

ClarkDietrich E-Screen can be used in stucco, stone veneer, brick, or under various siding installations to provide an effective method for drainage and ventilation in the wall system.

Moisture penetration is a prevalent issue in wall systems and creates a range of problems from cracking to complete failure of the wall. Without a rainscreen, moisture can intrude past the outer surface of the wall and become trapped in the system, creating issues with rusting and mold growth that can structurally compromise the system. By using ClarkDietrich E-Screen with a Top Vent Track and Vented Drip Flashing, the water inside the wall is drained away more efficiently and the increased ventilation properties allows the system to dry out more effectively.

Key Features

- 95% open design creates a continuous capillary break and a channel for moisture to drain away from the wall system while accelerating the drying time

- The durable polymer material is corrosion-resistant, rust-proof and mildew/mold-resistant

- Minimizes cracking, staining, peeling, and blistering of exterior finishes

- Easy to Install - more cost effective and easier to install than traditional furring methods

- The 2-Ply design is comprised of a backer fabric that deflects the stucco away from the open design and improves the tensile and compressive strength properties of the rainscreen - this fabric also provides a built-in insect screen

Commonly used behind:

- Stucco

- Stone Veneer

- Siding

Click links below to find out more:

Z-Girt

ClarkDietrich Z-Girt is used as a primary rainscreen framing component with depths matching common exterior insulation thicknesses while providing a uniform plane for cladding attachment. It can be installed in a horizontal or vertical orientation. The type of fastener and spacing will vary based on application.

Key Features

- Available in various depths from 1-1/2" to 4"

- Standard 12'-2" length

- Structural properties and load capacity tables available

- 1-1/2” wide flange for easy screw attachment

- Prepunched holes in flanges at 4" o.c. for easy attachment

- Slotted holes in web for moisture weeping

- ”Toed in” leg for strength and to grip rigid insulation

Commonly used behind:

- Cladding Facades

Click here For more information

Contact ClarkDietrich Technical Services at 888-437-3244 for rainscreen questions.

Code Approvals & Performance Standards

- ASTM C1063 Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster

- ASTM C1780 Standard Practice for Installation Methods for Cement-based Adhered Masonry Veneer

- ASTM C1861 Standard Specification for Lathing and Furring Accessories, and Fasteners, for Interior and Exterior Portland Cement-Based Plaster

- ASTM D256 Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

- ASTM D638 Standard Test Method for Tensile Properties of Plastics

- ASTM D648 Standard Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position

- ASTM D1784 Standard Classification System and Basis for Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds

- ASTM D4216 Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) and Related PVC and Chlorinated Poly(Vinyl Chloride) (CPVC) Building Products Compounds

- ASTM E2925 Standard Specification for Manufactured Polymeric Drainage and Ventilation Materials Used to Provide a Rainscreen Function

- SDS Vinyl Corp PVC Compounds