Clips melt away under intense heat, allowing a fire-damaged structure to collapse, while keeping the firewall barrier in place to protect the adjacent units

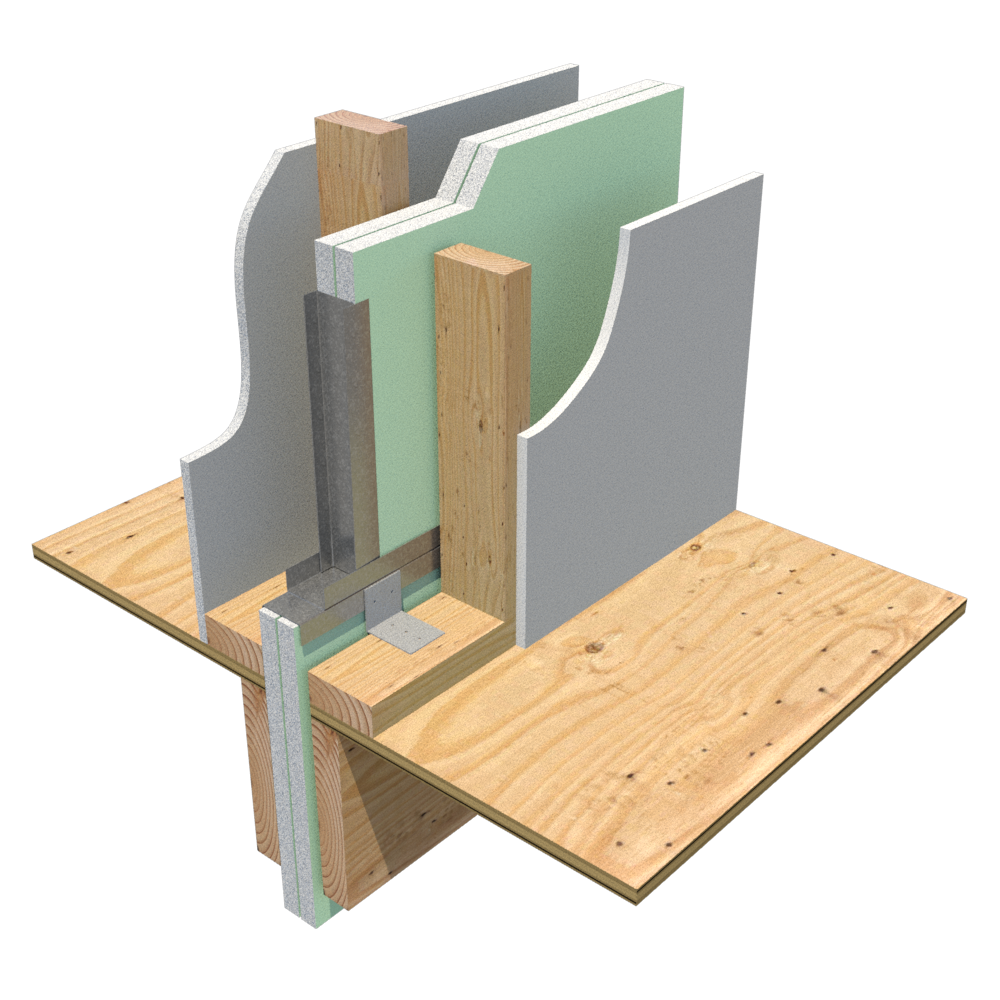

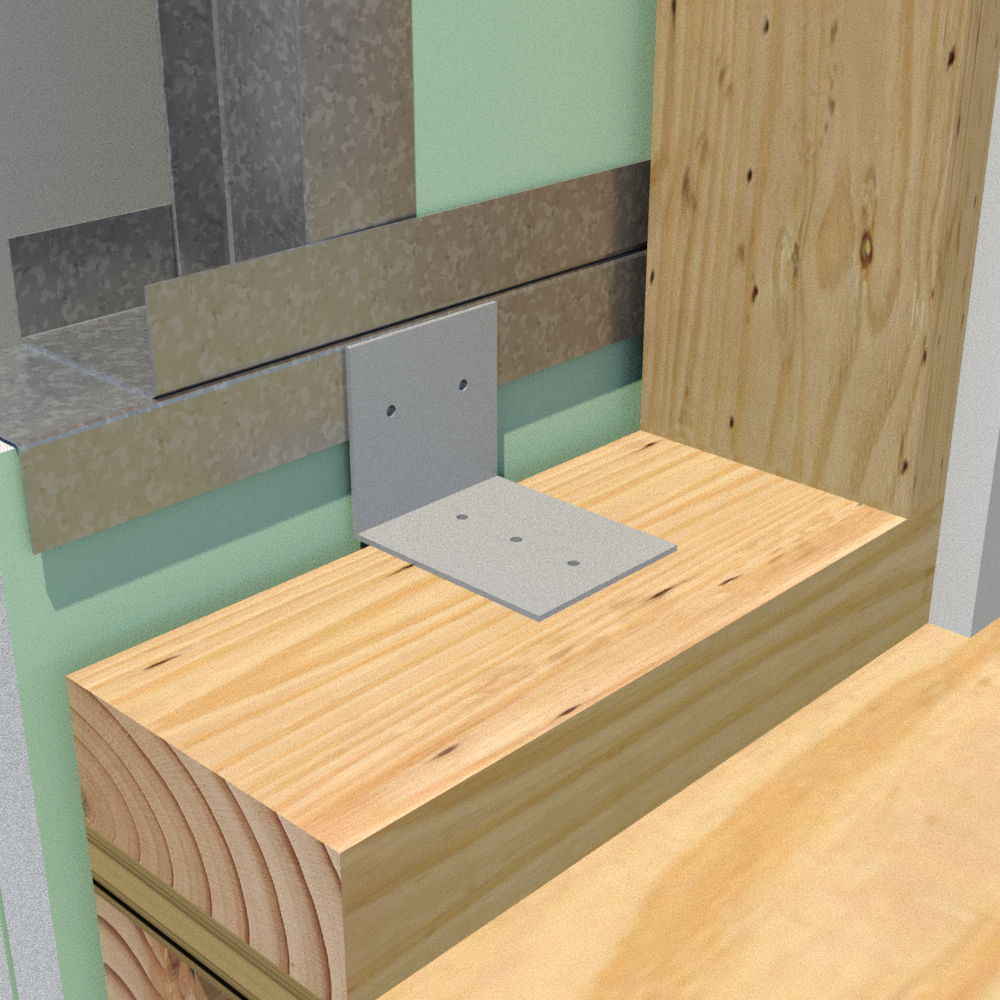

The clips are used to hold the area separation wall assembly in place at the floor, roof and truss line between adjacent units.

ClarkDietrich Aluminum Burn Clips are used as part of the ClarkDietrich H-Stud Area Separation Wall assembly and are designed to melt and break away when exposed to fire. The clips are used to hold the area separation wall assembly in place at the floor, roof and truss line between adjacent units.

Should a fire break out in one unit, the Aluminum Burn Clips on the fire-ridden side of the area-separation wall will melt, allowing the wall structure for that side to collapse. The Aluminum Burn Clips on the non-fire side will remain intact and hold the area separation wall in place as a barrier to contain the fire within the unit of origin.

Other custom Breakaway Clip lengths available

* For use with 3 Hour Design Assembly based on GA File No. ASW 2600 (USG)

Check listed Fire Rated Assembly Reports (in Technical Data Tab) for details of construction, thickness and length of required burn clips.

- Tested and approved with most major gypsum and shaftliner manufacturers

- Must be used in conjunction with H-Stud Area Separation Wall Assembly

- Prepunched for easy attachment

- Clip Express Sales at 866-638-1908 or clipexpress@clarkdietrich.com

- Technical Support at 888-437-3244 or support@clarkdietrich.com

Product Data & Ordering Information

| Member | Size | Thickness |

|---|---|---|

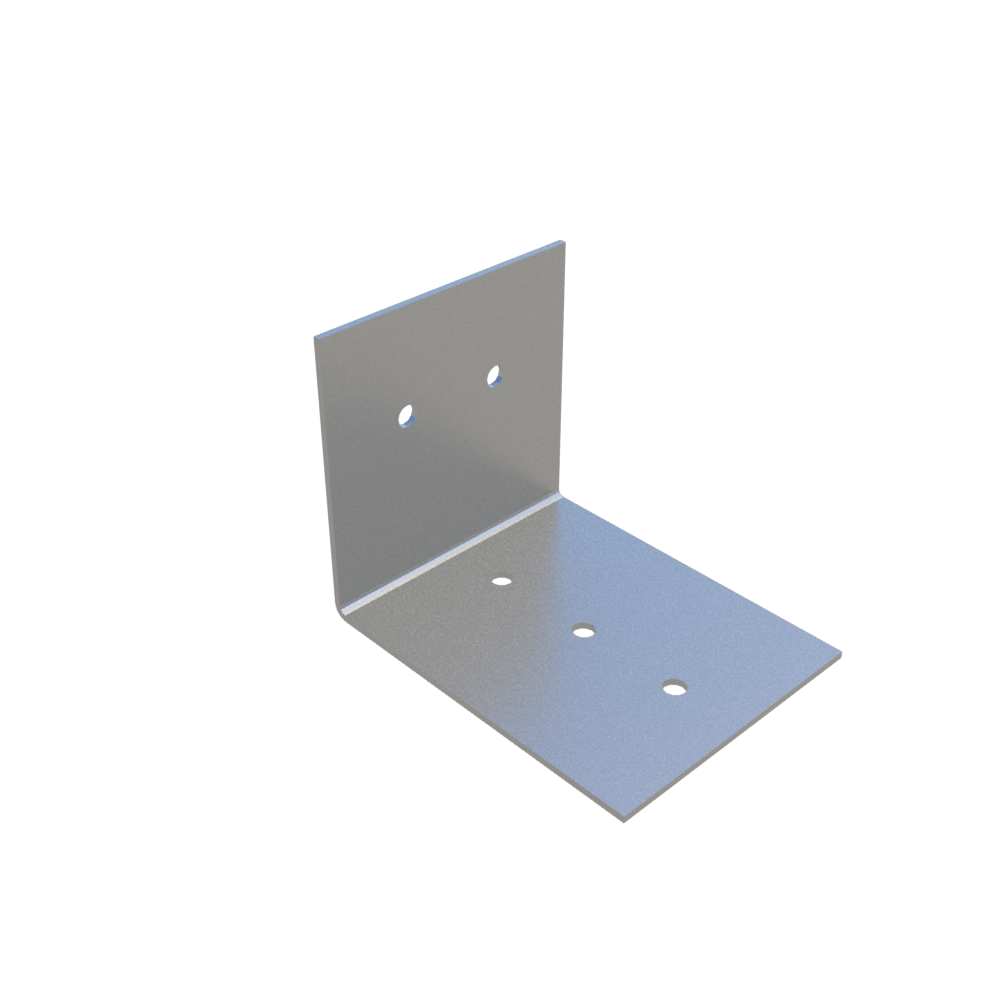

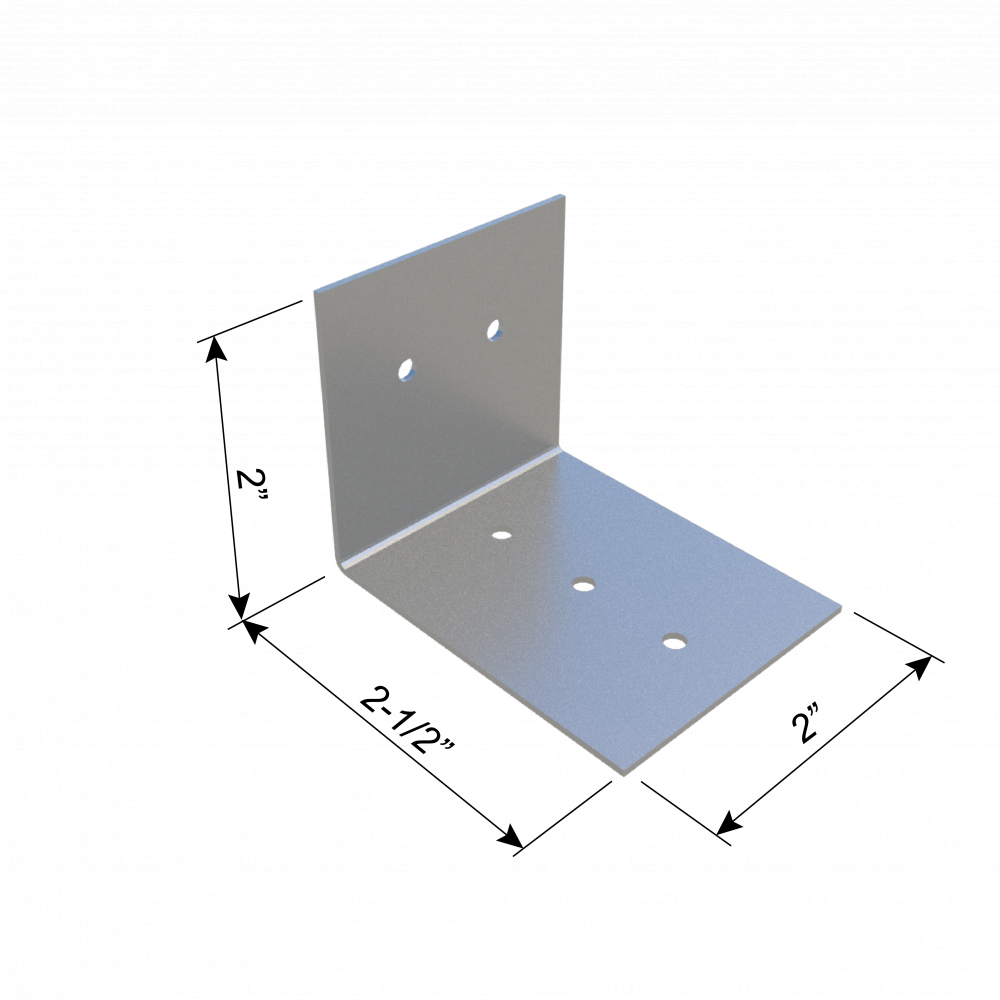

| AB - Breakaway Clip | 2" x 2-1/2" x 2" wide | 0.050" Aluminum Clip |

| AB63 - Breakaway Clip | 2" x 2-1/2" x 2" wide | 0.063" Aluminum Clip |

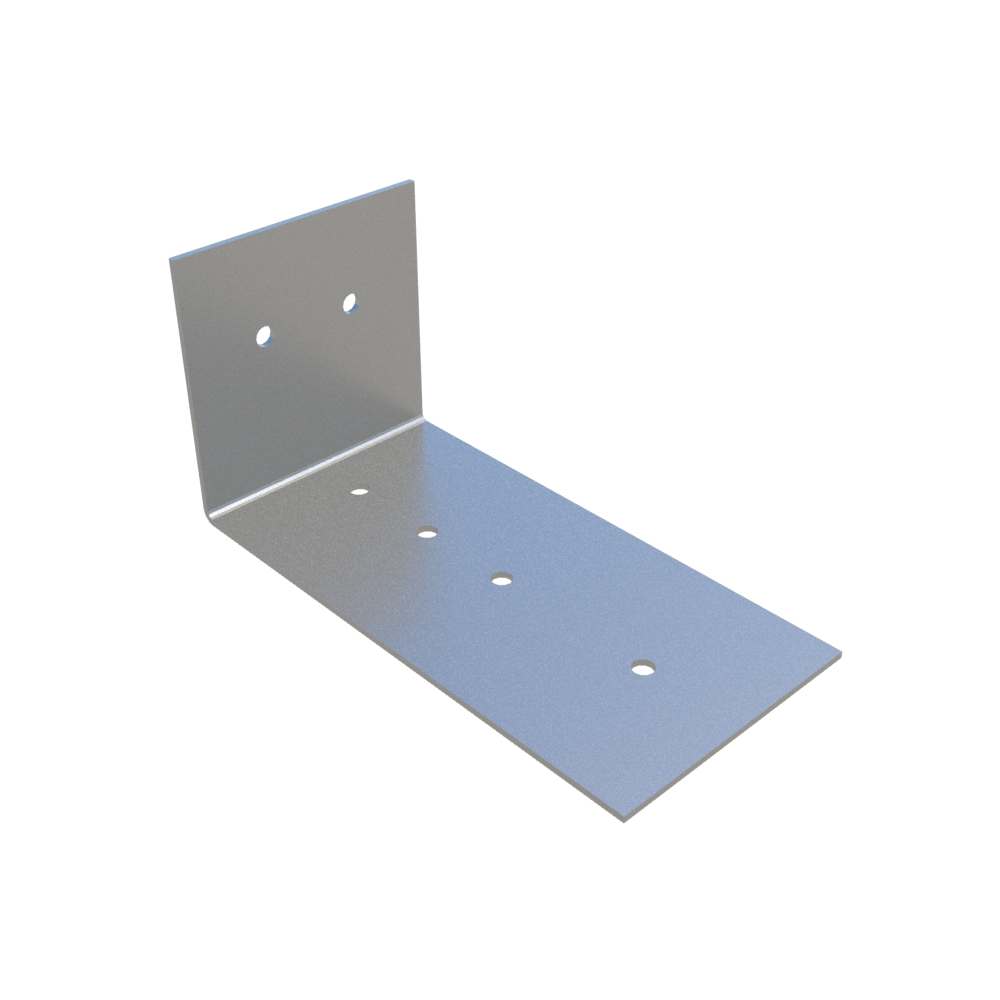

| AB45 - Breakaway Clip | 2" x 4-1/2" x 2" wide | 0.063" Aluminum Clip |

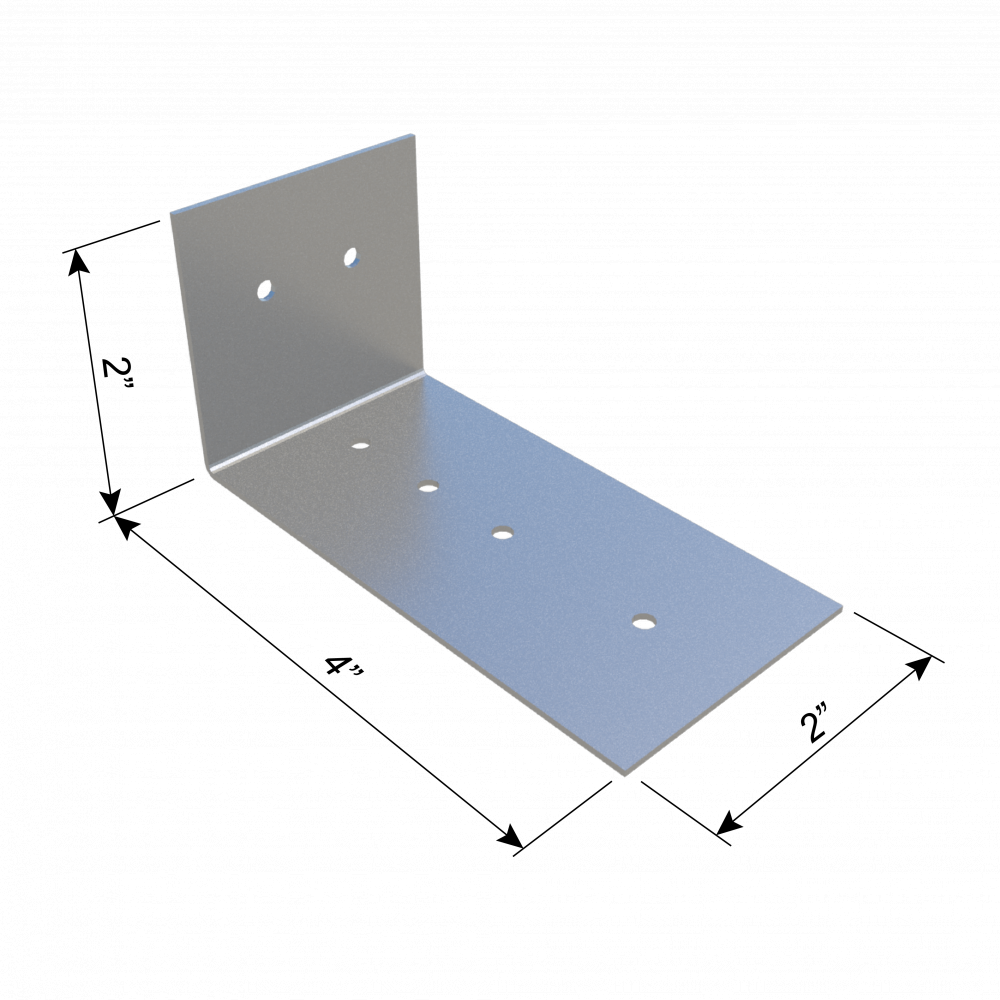

| AB40* - Breakaway Clip* | 2" x 4" x 2" wide | 0.063" Aluminum Clip |

| AB35 - Breakaway Clip | 2" x 3-1/2" x 2" wide | 0.063" Aluminum Clip |

| AB30 - Breakaway Clip | 2" x 3" x 2" wide | 0.063" Aluminum Clip |

All burn clips are manufactured using 5052 H32 aluminum

Check listed Fire Rated Assembly Reports below for details of construction, thickness and length of required burn clips

FIRE-RATED SYSTEMS

2 Hour Design Assembly:

- Intertek Fire-Rated Design - 2 Hours, Non-Bearing Symmetrical Area Separation Wall

- LISTING INFORMATION of ClarkDietrich Steel 'H' Stud and 'U' Track Fire-resistance-rated Area Separation Wall Assemblies (9/7/16)

2 Hour UL Listings:

3 Hour Design Assemblies:

UL Design No. W454 (National Gypsum Co.)

(2) Layers of 1” thick gypsum board liner panels fit into H-Studs w/ (1) layer of 5/8” thick gypsum board on each side of wall assembly. Standard 2-1/2” long Aluminum Breakaway Clips can be used to secure assembly

UL Design No. W467 (CertainTeed Gypsum)

(2) Layers of 1” thick gypsum board liner panels fit into H-Studs w/ (1) layer of 5/8” thick gypsum board on each side of wall assembly. Standard 2-1/2” long Aluminum Breakaway Clips can be used to secure assembly

GA File No. ASW-2600 (USG Corporation)

(2) Layers of 1” thick gypsum board liner panels fit into H-Studs w/4" min aluminum burn clips required to accommodate the 2" mineral insulation

GA File No. ASW-2601(GP Gypsum Corporation)

(2) Layers of 1” thick gypsum board liner panels fit into H-Studs w/4" min aluminum burn clips required to accommodate the 2" mineral insulation

*** Reference design assemblies and gypsum board manufacturer for details of the wall system ***

Installation

- Attach an aluminum burn clip to the completed area-separation wall assembly.

- One clip should be located at each H-stud on both sides of the wall.

- Attach the aluminum burn clip to the H-stud with a screw.

- Attach to the adjacent framing with a screw or a nail, as applicable.

- Confirm that the wall is plumb and then secure the assembly to the adjacent wall using aluminum burn clips on both sides of the wall. Make sure to leave a 3/4" gap between the area separation wall and adjacent wall. Clip spacing is dependent on the height of the wall. Wall assemblies can be stacked to a maximum height of 50' or per the details of the applicable UL assembly.

Check listed Fire Rated Assembly Reports (in Technical Data Tab) for details of construction, thickness and length of required burn clips.

PRoduct submittal SHeets

Click the below Product Code to view Submittal/Tech Datasheet.

| Product Code | Description |

|---|---|

| AB, AB63, AB45, AB40, AB35, AB30 | Aluminum Burn Clip |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

- Clip Express Sales at 866-638-1908 or clipexpress@clarkdietrich.com

- Technical Support at 888-437-3244 or support@clarkdietrich.com