Used to secure U-channel to wall studs for lateral bridging

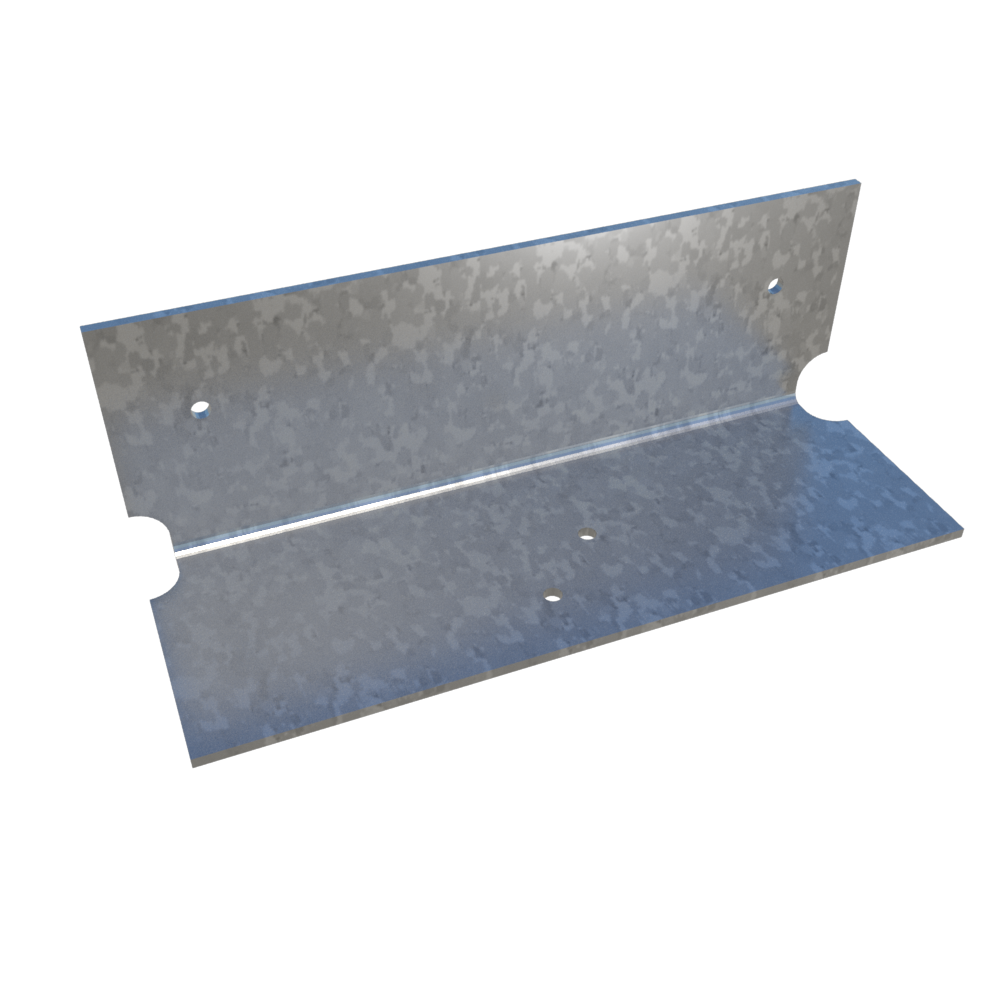

EasyClip™ X-Series™ Clip Angles have extra long legs (2" x 2") and are used to secure U-channel to wall studs for lateral bridging.

EasyClip™ X-Series™ Clip Angles are used to secure U-channel to wall studs for lateral bridging. U-Channel is passed through the stud knockout and an EasyClip™ X-Series™ clip is screw attached or welded to provide a rigid connection. X-Series™ clip angles and U-channel should not be used in lateral bridging when stud width exceeds 6". EasyClip™ X-Series™ clip angles are also used to secure one framing member to another or to attach and reinforce headers and sills in door and window openings. X-Series™ clips are prepunched for faster and more accurate fastener placement.

- 2" x 2" legs.

- Available in 3-3/8", 5-3/4", 7-3/4" and 9-3/4" lengths.

- Prepunched for faster and more accurate fastener placement.

Alternative Products:

- FastBridge™ Clip

- SwiftClip™ LS-Series™ Support Clip

- EasyClip™ U-Series™ Clip Angle

- EasyClip™ S-Series™ Support Clip

- Spazzer® 5400 and Spazzer® 9200 Spacer Bars

- Clip Express Sales at 866-638-1908 or clipexpress@clarkdietrich.com

- Technical Support at 888-437-3244 or support@clarkdietrich.com

Product Data & Ordering Information

| Product Code | Gauge | Mils | Design Thickness (in) | Size (in) | Pcs./Bucket |

|---|---|---|---|---|---|

| X543 | 16 | 54 | 0.0566 | 2 x 2 x 3-3/8 | 200 |

| X545 | 16 | 54 | 0.0566 | 2 x 2 x 5-3/4 | 170 |

| X547 | 16 | 54 | 0.0566 | 2 x 2 x 7-3/4 | 100 |

| X549 | 16 | 54 | 0.0566 | 2 x 2 x 9-3/4 | 100 |

| X683 | 14 | 68 | 0.0713 | 2 x 2 x 3-3/8 | 200 |

| X685 | 14 | 68 | 0.0713 | 2 x 2 x 5-3/4 | 100 |

| X687 | 14 | 68 | 0.0713 | 2 x 2 x 7-3/4 | 100 |

| X689 | 14 | 68 | 0.0713 | 2 x 2 x 9-3/4 | 80 |

| X973 | 12 | 97 | 0.1017 | 2 x 2 x 3-3/8 | 100 |

| X975 | 12 | 97 | 0.1017 | 2 x 2 x 5-3/4 | 100 |

| X977 | 12 | 97 | 0.1017 | 2 x 2 x 7-3/4 | 60 |

| X979 | 12 | 97 | 0.1017 | 2 x 2 x 9-3/4 | 60 |

Material Structural Grade 50 Type H (ST50H), 50ksi

Coating G90 (Z275) hot-dipped galvanized coating

See submittals for product weights

Installation

EasyClip™ X-Series™ Clip Angles are attached to cold-formed steel (CFS) framing members using #10 minimum selfdrilling screws driven through the clip holes into the steel framing. Four pilot clip holes are provided and should be filled when this clip is used in a bridging application. When this clip is used in other support or connection applications, refer to the allowable capacity chart to determine the appropriate number of fasteners required. As a general rule, fasteners should be evenly spaced (see figure 1). Clips can also be welded to the CFS framing. Connections to the building frame can be made with powder-actuated fasteners, drill-in concrete anchors or welding. When using the tabular values for a welded clip, provide a full weld to the structure, top to bottom, alongthe outside of the clip. A 3/4" minimum weld to the outside edge of the 2" leg is also recommended to control warping or to hold the clip in place before final welding. When installing powder-actuated fasteners, they must be placed 1/2" minimum away from the prepunched holes.

Code Approvals & Performance Standards

- ASTM A653 Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process

- ASTM A1003 Standard Specification for Steel Sheet, Carbon, Metallic- and Nonmetallic-Coated for Cold-Formed Framing Members

- SDS For ASTM A1003 Steel Framing Products For Interior Framing, Exterior Framing and Clips/Accessories

Product Submittal Sheets

Click the below Product Code to view Submittal/Tech Datasheet

| Product Code | Gauge | Description | |

|---|---|---|---|

| X543 | 16 | 2 x 2 x 3-3/8 | EasyClip™ X-Series™ Clip Angles |

| X545 | 16 | 2 x 2 x 5-3/4 | |

| X547 | 16 | 2 x 2 x 7-3/4 | |

| X549 | 16 | 2 x 2 x 9-3/4 | |

| X683 | 14 | 2 x 2 x 3-3/8 | |

| X685 | 14 | 2 x 2 x 5-3/4 | |

| X687 | 14 | 2 x 2 x 7-3/4 | |

| X689 | 14 | 2 x 2 x 9-3/4 | |

| X973 | 12 | 2 x 2 x 3-3/8 | |

| X975 | 12 | 2 x 2 x 5-3/4 | |

| X977 | 12 | 2 x 2 x 7-3/4 | |

| X979 | 12 | 2 x 2 x 9-3/4 | |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System

- Clip Express Sales at 866-638-1908 or clipexpress@clarkdietrich.com

- Technical Support at 888-437-3244 or support@clarkdietrich.com