Telescopes in length to deal with variances during installation

TRAKLOC® allows you to order one length member and “adjust” the length accordingly to make up for variances in the slab. The two-piece TRAKLOC® Elevator Stud® member is compressed to accommodate stocking in a building elevator and then can be extended (telescoped) to the required length at point of installation.

A revolutionary development in cold-formed steel framing systems. Unlike traditional steel studs, which are cut to length for varying jobsite conditions, TRAKLOC allows you to order one length member and “adjust” the length accordingly to make up for variances in the slab. The TRAKLOC Stud and TRAKLOC Track systems consists of a traditional-style framing member combined with an interlocking adjustable component. The adjustable portion allows for telescopic length adjustments and can accommodate variances in the slab, minor wall heights per floor, etc. The interlocking component of the stud and track eliminate the need for most connections!

Not all TRAKLOC products are available in all markets. Please check with your local ClarkDietrich sales representative for availability in your area.

The TRAKLOC product line is licensed under the following U.S. and Foreign Patents:

- U.S. Patent No. 7,223,043

- U.S. Patent No. 7,594,331

- U.S. Patent No. 8,061,099

- U.S. Patent No. 8,074,416

- Japan Patent No. 4934868

- Japan Patent No. 5156889

- Australia Patent No. 2006201344

- Australia Patent No. 2005332657

TRAKLOC® ELEVATOR STUD® (TLE)

The TRAKLOC Elevator stud member arrives in a compressed position to accommodate stocking in a building elevator and then can be extended (telescoped) to the required length at point of installation. This reduces the cost of stocking long studs on floors accessible only by elevators and stairways.

Stud Profile Information:

Web Depths: 2-1/2", 3-5/8", 4" and 6"

Flange Width: 1-1/4"

Lip Size: 0.288"

Material Thicknesses:

- 24mil (20EQ) 57ksi

- 30mil (20ga DW) 33ksi

- 33mil (20ga) 33ksi

- 18mil available only for large projects. Please contact sales.

All material: G40 (G60 available as special order)

Note: TRAKLOC Elevator studs over 21'-0" will be supplied in 2 components (unassembled).

For more info, see TRAKLOC Elevator Stud Catalog Page

Storage Requirements:

TRAKLOC is a dynamic system consisting of two moving parts. To maintain the telescoping feature of this system, it is important to store TRAKLOC studs indoors, free of excessive dust and airborne particulates.

TRAKLOC Stud Profiles (TLD)

Stud Profile Informaiton:

Web Depths: 2-1/2", 3-5/8", 4" and 6"

Flange Width: 1-1/4"

Lip Size: 0.288"

Material Thicknesses:

- 18mil (25ga) 33ksi (18mil available only for large projects - Please contact Sales)

- 24mil (20EQ) 57ksi

- 30mil (20ga DW) 33ksi

- 33mil (20ga) 33ksi

All material: G40 (G60 available as special order)

TRAKLOC studs are available in three configurations:

TRAKLOC Fixed Length Stud (TLF)

TRAKLOC Deflection Stud (TLD)

TRAKLOC Elevator Stud (TLE)

For more info, see TRAKLOC Stud Profile Catalog Page

TRAKLOC Track

Track Profile Information:

Web Depths: 2-1/2", 3-5/8", 4" and 6"

Leg Width: 1-3/8"

Material Thicknesses:

- 18mil (25ga) 33ksi (18mil available only for large projects. Please contact sales.)

- 24mil (20EQ) 57ksi

- 30mil (20ga DW) 33ksi

- 33mil (20ga) 33ksi

All material: G40 (G60 available as special order)

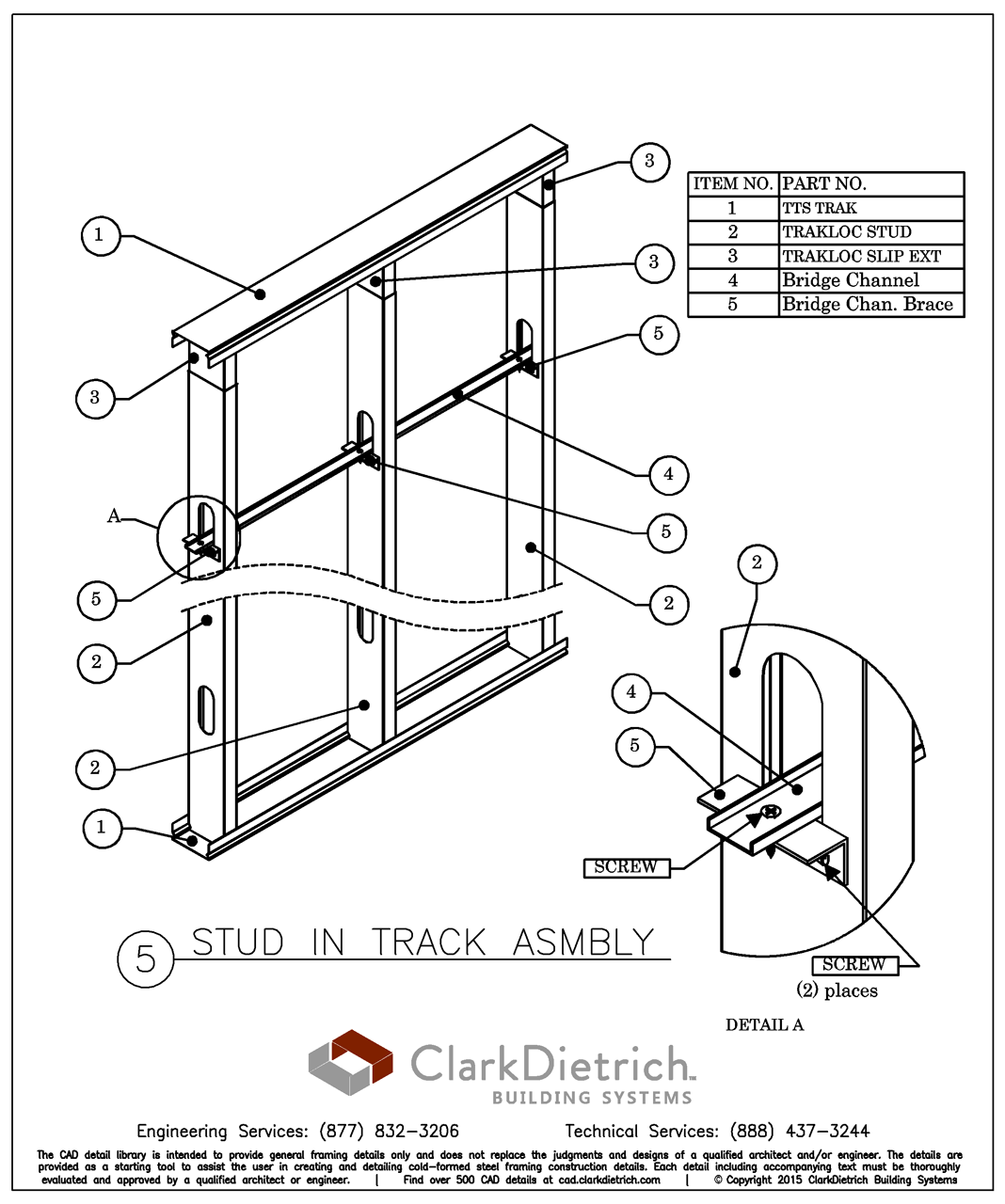

TRAKLOC track has two unique features. The most obvious feature of the TRAKLOC track is the V-groove rolled into the flanges of the track to match the swaged ends of the TRAKLOC stud. Next, are the dimples pressed into the center of the web. Together, the V-groove and the dimples provide a positive connection between stud and track without the need for mechanical fasteners.

TRAKLOC track standard length is 10' 0". Shorter lengths are available for non-standard conditions.

NOT ALL TRAKLOC PRODUCTS ARE AVAILABLE IN ALL MARKETS. PLEASE CHECK WITH YOUR LOCAL SALES REPRESENTATIVE FOR AVAILABILITY IN YOUR AREA.

Features and Benefits

Another added benefit to the TRAKLOC system is that screw attachment of the stud and track is not required. The patented swage end formation in the stud, combined with the swaged forming of the track, allows for the two members to “interlock” with no need for screw attachment. The knurling along the web of the track allow for minor adjustments to be made while keeping the members solidly locked in place. TRAKLOC steel framing members come in standard widths of 2-1/2," 3-5/8", 4" and 6".

- Twists and locks into place. Studs can be installed from the ground, greatly reducing time spent climbing ladders and scaffolding.

- Installation of TRAKLOC is ICC-ES approved without the use of fasteners to attach the studs to the top or bottom track. ICC-ES Report ESR-1464

- Significant productivity gains are possible versus conventional stud and track framing. This results in substantial installed cost savings!

- Safer Framing System™ reduces jobsite hazards. Less time spent climbing scaffolds, ladders, lifts and bending over to install screws result in fewer job related injuries and reduced workers compensation costs.

- Less cutting of studs significantly reduces material scrap and waste.

- Less noise, less steel shavings and improved air quality.

- Allows for seismic and live-load vertical inter-floor deflection in the stud, not the track. This feature eliminates the need for deflection tracks in fire-rated head-of-wall assemblies

Limitations of Use

- TRAKLOC is designed for interior non-load-bearing walls only.

- Do not stack

THE FASTEST WAY TO FIND TRAKLOC LIMITING HEIGHTS

Single submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

For product data sheets with section properties and limiting heights for all TRAKLOC Stud & Track profiles available, use the Launch SubmittalPro link found on the bottom of this page.

(All tables below are based on the ICC ESR-1464 Report)

Please review all TRAKLOC Drywall Framing Installation Recommendations before ordering or installing TRAKLOC's System

Limiting Heights

COMPOSITE ASSEMBLIES

Composite limiting height data can be applied to walls where 5/8” gypsum board is installed vertically on both flanges of the stud for the full height of the wall and installed in accordance with ASTM C840-2013. TRAKLOC® composite limiting heights were determined in accordance with ICC-ES AC86-2012.

Composite Limiting Height Tables

NON-COMPOSITE ASSEMBLIES

Non-composite conditions are common in all structures. When the gypsum board stops at the ceiling level, but the stud continues to the deck, it is a non-composite condition. While there may be advantages to contacting Technical Services or a Design Professional, many conditions can be covered by limiting heights tables shown below. When in doubt, call our complimentary Technical Services Hotline at 888-437-3244.

Distance of unbraced length (Lu) can be found in TRAKLOC® Physical and Structural Properties shown in SubmittalPro.

Non-Composite Limiting Heights Tables

Deflection / Head-Of-Wall

Deflection is the amount of bend, or "give" a structure experiences because of a load. In non load-bearing walls, this vertical movement can be caused by a number of reasons (live-load, seismic activity) which will damage walls if not accounted for. This vertical movement is typically accounted for on each level where the top of the wall(s) are designed to move.

With conventional material deflection is accomplished with either deep leg or slotted track. The slotted systems are more expensive, and both systems install with a high degree of attention to detail that is frequently not adhered to. With the TRAKLOC Drywall Framing System deflection is accomplished with the stud, more specifically with the insert of the stud, eliminating the need (and expense) of either of the specialty tracks or variance in the framing process.

Trakloc’s deflection insert provides a full inch of deflection (+/- ½”) while also allowing for 2 inches of stud height variability. As illustrated in the Component section, the deflection insert (TSE w-Deflection) and Trakloc’s standard insert (TSE) are the same, except the deflection insert has a 3” x 3/4" slot punched into the top of each flange. These slots allow the drywall screw to pass through the board and the TSO, while avoiding contact with the TSE.

The unique method by which the Trakloc Steel Framing system accounts for deflection eliminates the two most common mistakes made with conventional material. With deep leg track, many installers raise the stud off the bottom track to have it fit into the top track. This method places the load bearing capabilities on the screw, not on the stud which is out of spec. When using slotted top track, the top screw is often either too high or too low, both of which are also out of spec. Trakloc’s® slotted insert eliminates both pitfalls.

Head-Of-Wall Deflection Required With TRAKLOC Elevator Stud?

Elevator Studs are not for deflection by themselves. However, deflection can be achieved by using MaxTrak® slotted deflection track or deep leg track

with lateral bracing at the head of the wall.

Sound Rated Systems

The below letter presents Veneklasen Associates, Inc. review of the acoustical differences between ClarkDietrich ProSTUD® and TRAKLOC® variations.

Veneklasen Associates - Acoustical review of ProSTUD® and TRAKLOC®

Based on the information currently available, Veneklasen Associates, Inc. (VA) professional opinion is that the acoustical performance of the TRAKLOC® will be similar to the ProSTUD® meaning that the reported STC ratings for the ProSTUD® can be used interchangeably with the TRAKLOC®.

Fire-Rated Systems

The TRAKLOC system is Intertek Warnock Hersey Design Listed and approved for use in both one and two-hour fire-rated assemblies requiring deflection in accordance with ASTM E119 and ASTM E1966.

HEAD-OF-WALL JOINT SYSTEMS

1 Hour Design Listings

2 Hour Design Listings

NON-LOADBEARING WALL ASSEMBLIES

1 Hour Design Listings

2 Hour Design Listings

INSTALLATION

TRAKLOC ICC ESR-1464 approval does NOT require the use of screws; however field experience suggests the use of screws in the following:

- High volume areas like door openings.

- Beginning and end of wall runs, especially with open corners.

- Header assemblies, to provide strength.

- In projects with multiple trades or tight schedules. Placing screws on one side minimizes the need to place studs back on layout.

Please review all TRAKLOC Drywall Framing Installation Recommendations before ordering or installing TRAKLOC's System

The thought process for installing TRAKLOC Drywall Framing does not fundamentally differ from installing conventional stud and track in that you will still have open or closed corners, door and window headers, and king and jack studs (as called for in the plans). What you will not have are returns (mitered cuts) or the material build up caused by these cuts as these are replaced with pre-made cripple studs and header clips. But, as with conventional material, installation starts with the track.

INSTALLING TRAKLOC BOTTOM TRACK OR TOP TRACK

FOR A FIXED STUD SYSTEM

As a rule, TRAKLOC track installs the same as conventional track. This applies to top and bottom track, open and closed corners, with the only exceptions being the splice method for top freestanding track, when the Split Lap would become your splice of choice. However, with TRAKLOC track you will want to be a little more conscience of where the layout marks are as using too many pins may interfere when twisting a TRAKLOC stud into place. The only other suggestion would be that when cutting bottom track, also cut a piece for the door opening as this will become the track used in the door header assembly. Except for these two considerations, installation is the same.

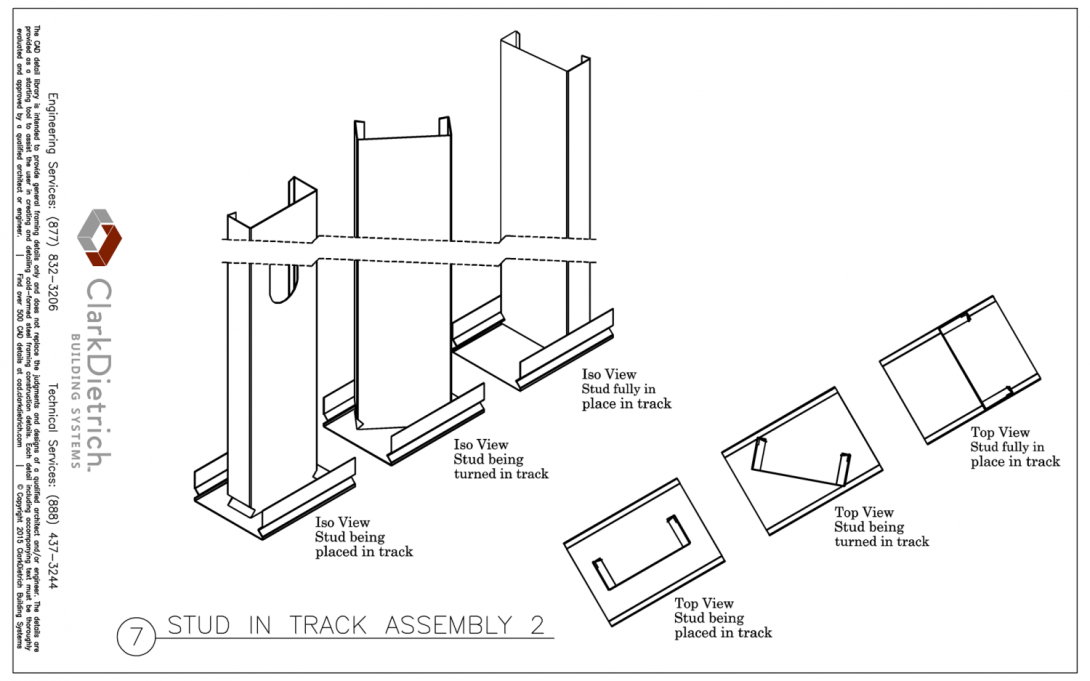

INSTALLING TRAKLOC STUDS

You will be amazed at how easily TRAKLOC studs install, and depending on the thickness and wall height, how easily it can be done from the ground. Vertically position the stud between the track, raise the top end (the end with the Stud Extension) until it seats fully into the top track and twist until it becomes perpendicular to the track. It does not matter whether you twist clockwise or counter-clockwise, but you will want to start your twist with the leading edge right on the layout mark. Once twisted, if your stud is not positioned on the top layout mark, just reach up and tap the stud into position, then pull down on the Main Stud while twisting the stud to be parallel to the bottom track and fully seat it into the lower track. Once seated, release the twist to lock the bottom of the stud into the lower track. If the stud is not on the layout mark, simply tap the stud with your boot in the direction it needs to go and you are done. Installation is now complete.

With TRAKLOC there is no need to measure and cut your stud to length, no need to climb on ladders or bakers scaffolds to screw the top into the track, no stooping to screw the bottom into place, less chance of repetitive motion injury, less chance of shards created by the screw from falling into your eyes, and less scrap to trip over on the job site. Real world experience has shown that you will be able to install substantially more lineal feet of studs while expending less energy than with conventional material.

INSTALLATION WHEN DEFLECTION AT HEAD-OF-WALL IS REQUIRED

TRAKLOC’s deflection insert provides a full inch of deflection (+/- ½”) while also allowing for 2 inches of stud height variability. As illustrated in the Component section, the deflection insert (TSE w-Deflection) and TRAKLOC’s standard insert (TSE) are the same, except the deflection insert has a 3” x ¾” slot punched into the top of each flange. These slots allow the drywall screw to pass through the board and the TSO, while avoiding contact with the TSE

CORNERS – OPEN & CLOSED

Field installers report that they find open corners to be the better option, but TRAKLOC accommodates both. It has been observed that closed corners involve more cutting and therefore take more time.

HEADERS

One of the most substantial time saving elements of the TRAKLOC Steel Framing system is its treatment of headers. Headers are horizontal spans of track used between door and window openings to provide a horizontal screwing surface, as well as support for items such as duct work.

Instead of using miter cuts, TRAKLOC track should be cut to the size of the opening and attached with TRAKLOC Cripples Studs or TRAKLOC Header Clips. With this technique there are two alternatives.

Using TRAKLOC Header Clips requires less material while using all TRAKLOC Cripple Studs will provide more structure to the opening. Either of which are acceptable, but check your plans for guidance.

SILLS

It may appear that the V-Grove extends outside the web, but this is not so. At door header assemblies and other intersections of track and stud there is no material build up. When screws would be used, such as door header assemblies, it is recommended to screw into the V-Groove at a 45° angle so the screw head will be recessed.

HALF WALLS

Half walls are easily adjusted to the correct elevation and level with TRAKLOC Cripple Studs. It is recommended to place screws in the overlap to maintain a level surface and stabilize the structure.

SOFFIT INSTALLATION

Another use for TRAKLOC Cripple Studs are soffits. Soffits can be made on the ground, without cutting, and then installed. Layout four pieces of track and snap in the Cripple Studs where appropriate. Take one of the two “ladders” you have just created and install in the appropriate place as the vertical member, fastening it to the deck. Laser (or level) the bottom track to assure levelness and place screws in the overlaps to maintain its proper positioning. Take your second “ladder” and fasten it to the bottom of the vertical member and the wall studs.

Documents

Code Approvals & Performance Standards

- AISI S100-12 North American Specification for the Design of Cold-Formed Steel Framing Structural Members

- AISI S220-11 North American Standard for Cold-Formed Steel Framing - Nonstructural Members

- (Compliant to ASTM C645 , but IBC replaced with AISI S220 in IBC 2015)

- Section A4 Material - Chemical & mechanical requirements (Referencing ASTM A1003/A1003M)

- Section A5 Corrosion Protection (Referencing ASTM A653/A653M)

- Section C Installation - (Referencing ASTM C754)

- ICC-ES ESR-1464 TRAKLOC

- SDS For ASTM A1003 Steel Framing Products For Interior Framing, Exterior Framing and Clips/Accessories

Cost Comparison Calculator

Product Testimonials

Product Time Study

Product Substitution Forms

To simplify the Product Substitution Request process when ClarkDietrich’s Products are not listed in the Architectural Specification, select one of the CSI Forms in our ClarkDietrich Substitution Request Forms Page to help streamline the procedure.

For creating product submittals to attach to these forms use ClarkDietrich's SubmittalPro Product Submittal System.

- For submitting product samples to the Architect call (800) 543-7140 and request ClarkDietrich’s product samples.

Fire Ratings

The TRAKLOC system is Intertek Warnock Hersey Design Listed and approved for use in both one and two-hour fire-rated head-of-wall assemblies requiring deflection in accordance with ASTM E119 and ASTM E1966.

TRAKLOC® DRYWALL FRAMING SYSTEM - FAQS

What is TRAKLOC?

- TRAKLOC is a non-load bearing steel framing system for use in interior walls that is designed to save the contractor time in installation and to provide jobsite solutions.

- TRAKLOC has an ICC-ESR-1464 code approved stud-to-track connection where the stud twists and locks into the top and bottom track without the use of mechanical fasteners.

- TRAKLOC is manufactured in fixed lengths for through-grid or under-grid conditions and also in a two-piece telescoping adjustable-length configuration for deck-to-deck conditions requiring vertical deflection.

- TRAKLOC can be used in one-hour and two-hour fire-rated wall assemblies that require head-of-wall vertical deflection and non-rated walls that do not require deflection.

How does TRAKLOC save the steel framing installer time?

- TRAKLOC Adjustable Stud (TLA) accommodates for variations in floor to ceiling heights.

- Eliminates need to measure and cut studs on jobsite.

- Code approved twist-and-lock connection minimizes use of mechanical fasteners.

- TRAKLOC system allows for seismic and live-load vertical inter-floor deflection.

- TRAKLOC studs can be installed standing on the floor.

- Reduces time spent bending over or climbing ladders and scaffolds to install fasteners.

- Significantly reduces material scrap and waste resulting in a cleaner, safer jobsite.

- Safer jobsite and fewer accidents can result in lower workers compensation costs.

- TRAKLOC Elevator Stud (TLE) member can be collapsed to fit in building elevators.

- Reduces cost of stocking long studs on higher building floors with limited size elevators.

How does the TRAKLOC system allow for vertical inter-floor deflection?

- Vertical deflection is accommodated by the telescoping TRAKLOC Deflection Stud (TLD), not the track.

- Slots located in the side flange of the TRAKLOC Stud Extension allow drywall to be positively attached to the primary stud while still allowing for unrestrained cyclic movement between the TRAKLOC stud and TRAKLOC stud extension.

- Unlike slotted-track systems, TRAKLOC deflection system does NOT rely on labor-intensive field measuring, cutting and careful location of the fasteners.

Is TRAKLOC approved in my area?

- TRAKLOC meets the requirements of the International Building Code.

- ICC-ES Report No. ICC-ESR-1464

- TRAKLOC has been fire-tested in accordance with ASTM E119 and ASTM E1966.

- TRAKLOC is Intertek Design Listed and approved for use in one-hour and two-hour fire-rated head-of-wall deflection assemblies.

- TRAKLOC has been approved for use in the cities of Sacramento, San Francisco, Los Angeles, Las Vegas, Phoenix, St. Louis, Chicago, Milwaukee, New York, Miami, Nashville, Memphis, Charlotte, Washington D.C. and many other jurisdictions.

How much does TRAKLOC cost compared to conventional steel framing?

- Due to the significant reduction in labor expense TRAKLOC can be more advantageous than conventional steel framing materials on an installed cost basis. Installed cost can be less than conventional steel framing materials, depending on the type and complexity of the project.

What are the available TRAKLOC sizes and steel thicknesses?

- 2-1/2, 3-5/8, 4" and 6 Inch.

- TRAKLOC is manufactured in 18, 30 and 33 Mil thickness.

-

What is the minimum overlap on a TRAKLOC telescopic-stud assembly?

- This typically varies from 4" to 12". The minimum overlap length will be calculated at the time of manufacture based on specific project requirements such as wall height, lateral load and deflection limits specified by the project engineer.

-

What happens if you have to cut the swage off the stud?

- In isolated instances where you need to cut the swage off of a stud it can still be attached to the track with a mechanical fastener.

Is installation of TRAKLOC Track any different than conventional track?

- TRAKLOC top and bottom tracks are installed in essentially the same manner as conventional track. The same fasteners and tools are utilized.

- Framers will most often want to re-think their crew scheduling in order to realize maximum savings in installed costs given the shorter time required to frame in studs and header openings compared to traditional framing.

Can I install a TRAKLOC Stud anywhere along the TRAKLOC Track?

- Yes, the TRAKLOC Studs can be inserted anywhere along the length of the TRAKLOC Track, at regular as well as infinitely adjustable irregular intervals and spacing.

Can TRAKLOC be used in load-bearing walls?

- No, the TRAKLOC system is currently approved for use in non-load-bearing walls only.

What do I do if a plumber or electrician moves the TRAKLOC stud off layout?

- The dimpling in the center of the track greatly minimizes unwanted movement of the stud.

- However, if the TRAKLOC stud is moved off layout by other trades, the stud can be slid back into place.

- Drywall installers have commented that they find the ability of the stud to be moved slightly in order to adjust for off-layout stud spacing to be a positive characteristic of the TRAKLOC system.

What is the maximum length of TRAKLOC studs?

- This varies depending on the stud size, gauge, wall height and design loads. Refer to the TRAKLOC Limiting Wall Height Table.

Are all TRAKLOC studs telescopic?

- No, TRAKLOC studs are also available in fixed lengths as short as 12" and as long as you need them to be. However most framers prefer the flexibility and adjustability afforded by the telescoping product.

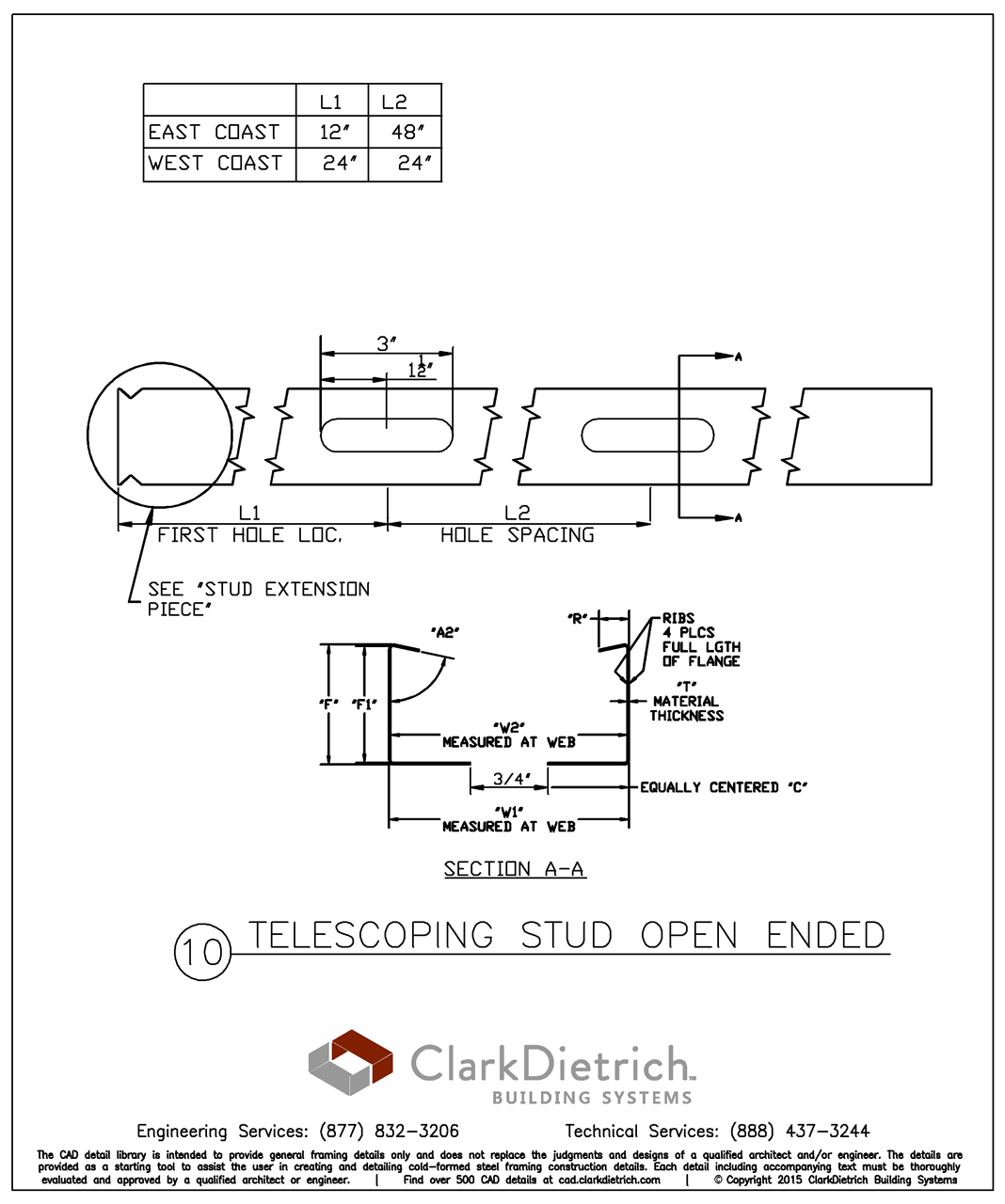

Do TRAKLOC studs have service holes?

- Yes, all TRAKLOC studs come with 4" x 1 1/2" service holes on 24" centers.

- These locations can be tailored to the customer's needs.

Can TRAKLOC be ordered in custom lengths?

- Yes, TRAKLOC can be ordered in custom lengths as short as 12" for header and soffit framing needs. Short length charges may apply.

How long has TRAKLOC been in use?

- TRAKLOC was first used in the United States in 2005.

How do I cut TRAKLOC studs and track?

- The design of TRAKLOC is intended to eliminate the need to cut studs. However, if you need to cut the stud or track, standard steel framing tools can be utilized.

- Just remember that as a rule, don't cut the swaged end of a stud. Simply slide out the TRAKLOC Stud Extionion, cut the open end of the main stud to the desired length, then "snap" the Stud Extionsion back into the end of the main stud.

Are mechanical fasteners ever used with the TRAKLOC system?

- Yes. Although the amount of mechanical fastening is greatly reduced, you will typically use screws at corners, king studs, header assemblies, etc. When screws are used, they are installed in the recess V-groove of the track, eliminating the "bump" in the drywall. This is especially beneficial around door and window headers and makes finishing the drywall cleaner, easier and faster.

- By allowing screws to be inserted into the track's "V-groove", the framer is able to shoot the screw in at a 45 degree angle to the wall instead of at a 90 degree angle as is the case with conventional framing. While this might not sound like a big deal, the screws are easier to get started and it greatly reduces the amount of bending from the knees and waist. This is seen by trade schools and apprenticeship programs as significant factors in reducing risks of knee and back strains and injuries.

How are door openings, window openings and soffits framed using TRAKLOC?

- Adjustable TRAKLOC short stud assemblies and header clips are available in pre-cut lengths as short as 12" to be used as "cripples" in header and soffit framing.

- This adjustability and pre-cut header clips allows headers and soffits to be framed much more efficiently.

CAD Details

Note: to view all of ClarkDietrich's CAD details, visit the CAD Details Library.

ClarkDietrich SubmittalPro®

The Fastest way to find product information

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

Most common TRAKLOC submittals can be found below:

| Size / Thickness | System Type | Stud Profile | Track Profile |

|---|---|---|---|

| 3-5/8" 24mil (20ga EQ) | (TLE) TRAKLOC Elevator Stud | 362TLE125-24 | 362TTS137-24 |

| 3-5/8" 30mil (20ga DW) | (TLE) TRAKLOC Elevator Stud | 362TLE125-30 | 362TTS137-30 |

| 3-5/8" 24mil (20ga EQ) | (TLD) TRAKLOC Deflection Stud * | 362TLD125-24 | 362TTS137-24 |

| 3-5/8" 30mil (20ga DW) | (TLD) TRAKLOC Deflection Stud * | 362TLD125-30 | 362TTS137-30 |

| Find all profiles in SubmittalPro® Product Submittal System | |||

* Minimum order is required, contact sales for requirements.

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about creating product submittals or using SubmittalPro.