Quick, Easy Installation

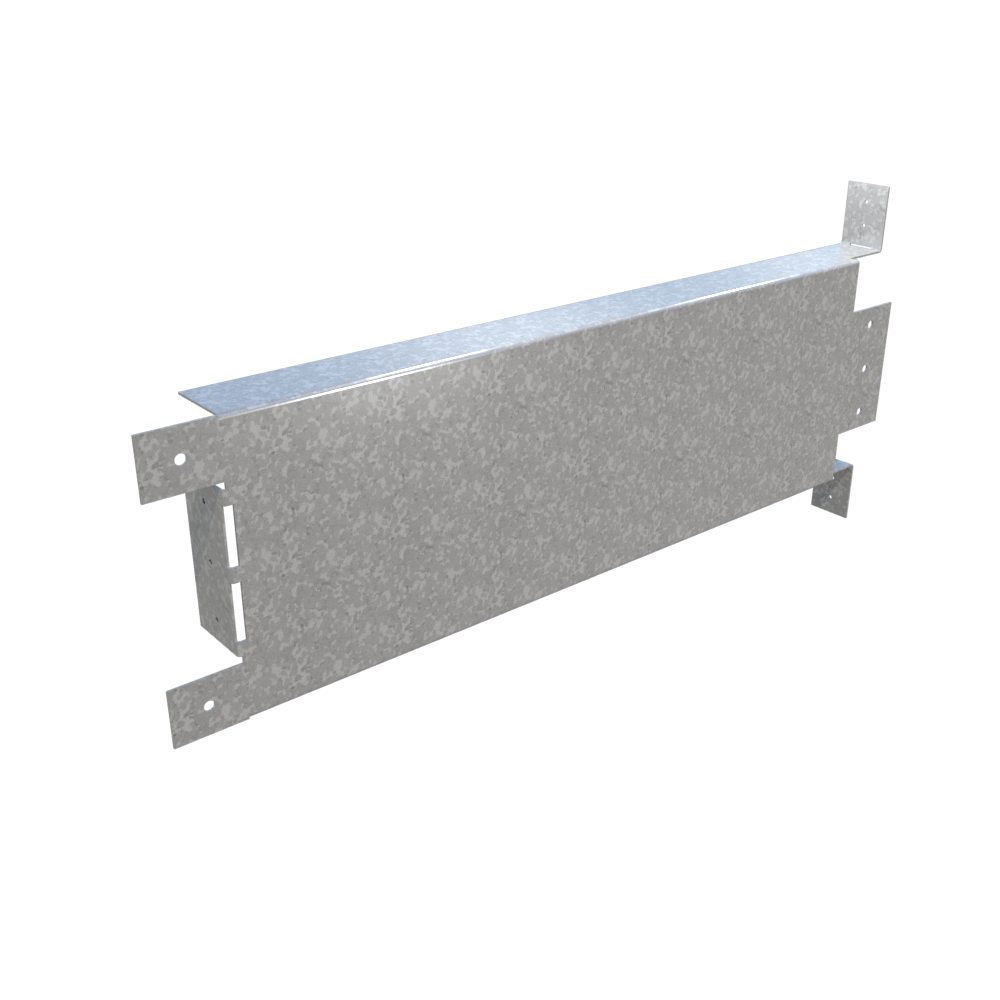

The Backer Bar was specifically designed to meet the demand for the attachment of multiple items and heavier items to interior partitions. Provides superior connection shear and pullout strength for handrails, shelves and other wall fixtures.

Designed and patented by Bailey®. Manufactured, tested and distributed in the USA by ClarkDietrich®.

Today’s building professionals require solutions to allow the attachment of such products and accessories to the interior partition walls. Traditionally, backing systems have been costly, time-consuming and not necessarily performing to the required code specified load requirements. Backer Bar, designed for use on non-structural and structural studs.

Typical Applications:

- Wall-Mounted Televisions

- Hospital Handrails

- Towel and Shower Bars

- Cabinets and Shelves

Features and Benefits:

- Installs quickly and easily

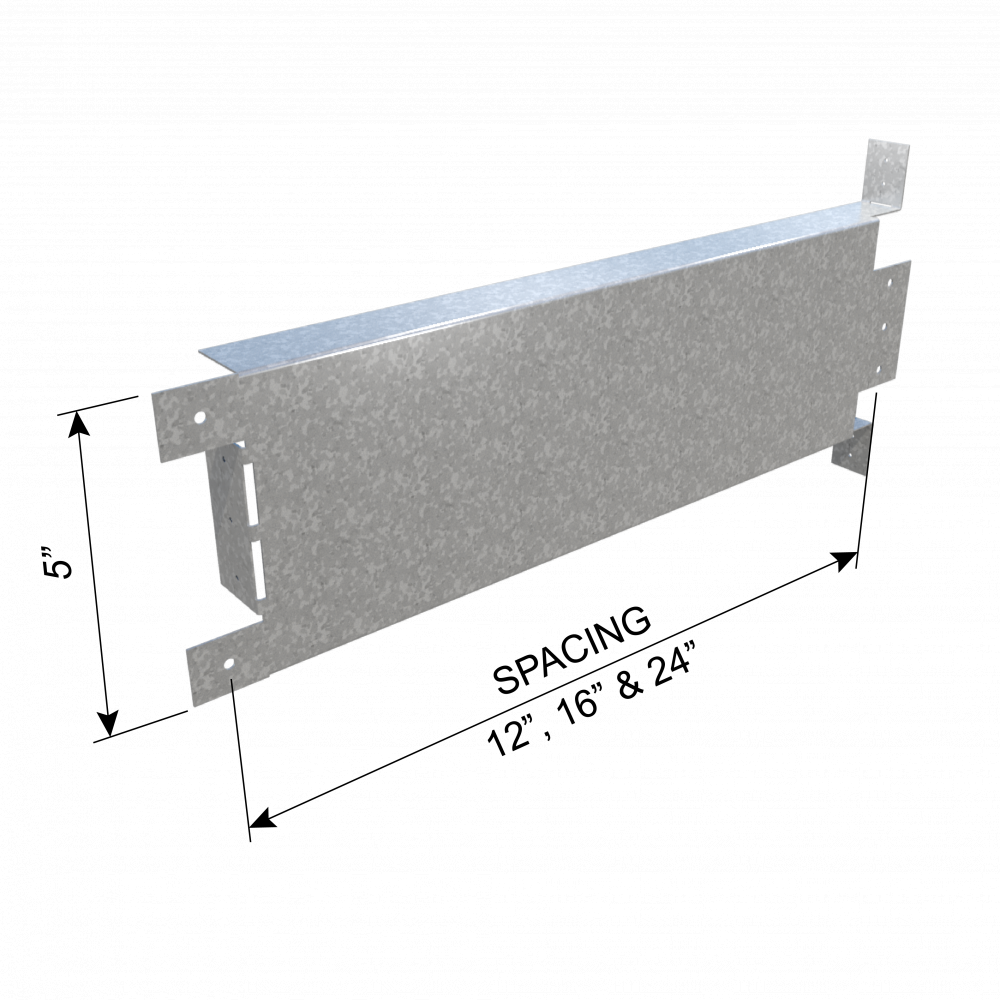

- Available in 12", 16" and 24" spacing

- For use on non-structural and structural studs

Canada Patent Pending – 2,811,362

USA Patent – 9,062,455

Product Data & Ordering Information

Material: Grade 50ksi min. yield strength, G90

33mils: 20ga STR, 0.0346” Design Thickness, 0.0329“ Min. Thickness

Dimensions:

Leg: 1-1/4”

Width: 5”

Lengths: For 12”, 16" and 24”o.c spacing

- Clip Express Sales at 866-638-1908 or clipexpress@clarkdietrich.com

- Technical Support at 888-437-3244 or support@clarkdietrich.com

Load Tables

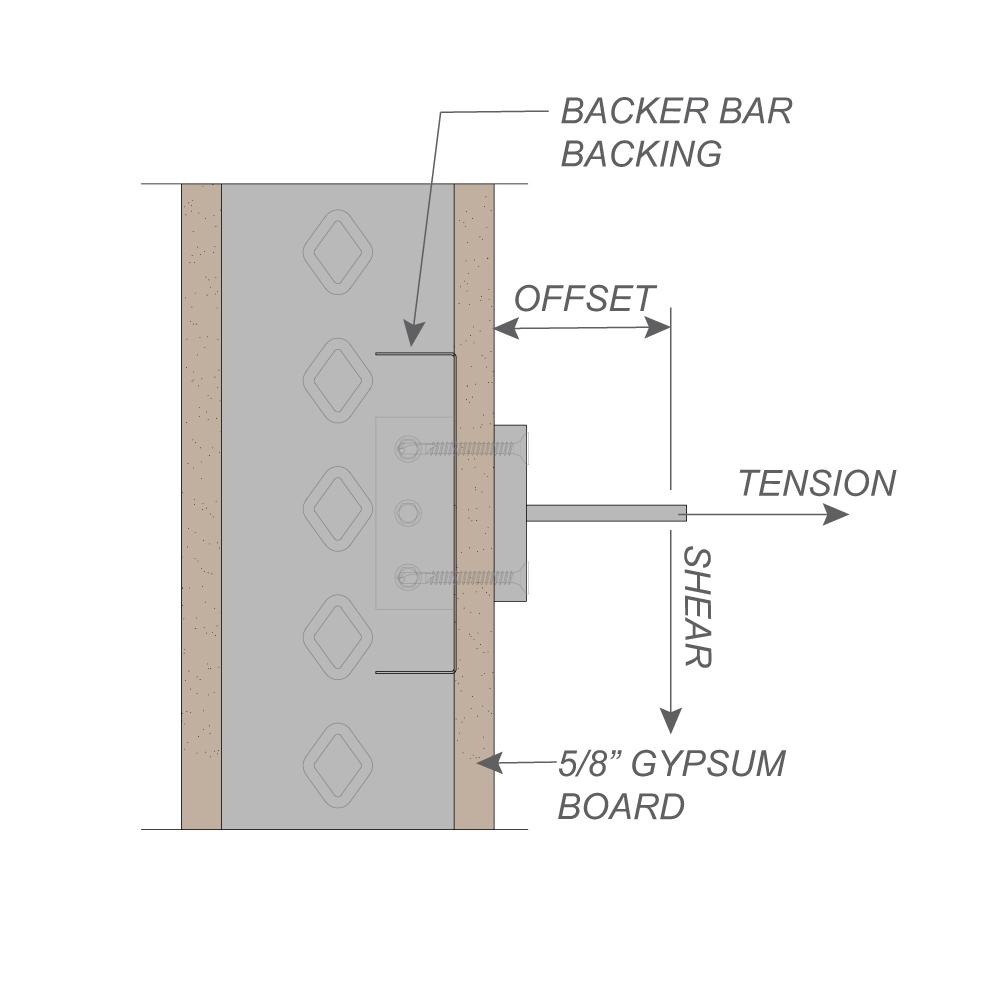

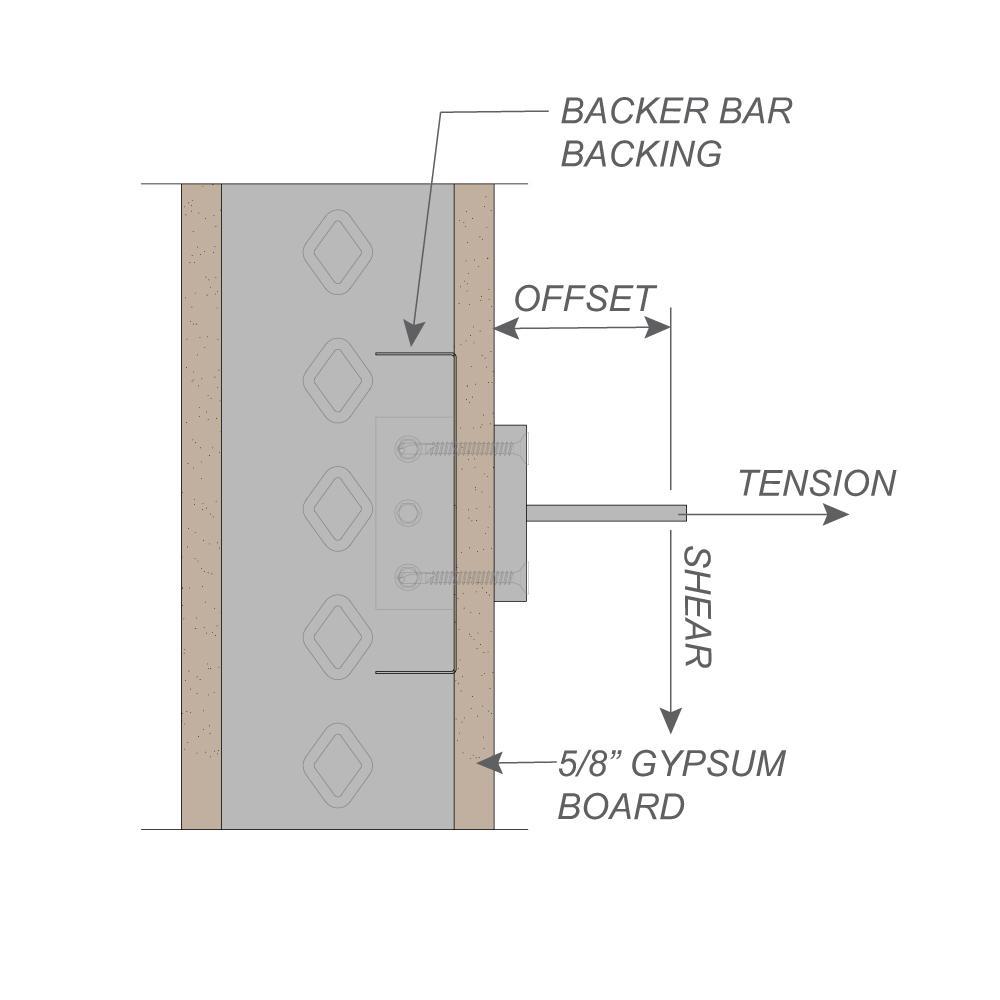

| INSTALLATION CONDITOIN | NOMINAL (LBS) |

|---|---|

| Shear / 0" Offset | 2310 |

| Shear / 1" Offset | 805 |

| Shear / 3" Offset | 255 |

| Tension | 650 |

Notes:

1. Listed load values are nominal test load values, appropriate safety factors/resistance factors should be applied by the designer for calculating loads for intended use.

2. Shear / Offset (moment-rotation) Load refers to load directed in the plane of the wall.

3. Tension Load refers to load directed perpendicular to wall surface.

4. Tabulated loads include the contribution of 5/8" gypsum board.

5. Test loads were applied to the gypsum board and backing system through a 1/2" thick, 2-3/4" diameter steel plate secured with (4) #12 hex head screws.

6. Loads were applied directly through the steel plate or to a steel rod that cantilevered from the plate.

7. Typical failure mode in backing testing was the gypsum board failure.

8. 24-in o.c. stud spacing test results were similar/identical to 16-in o.c. test results.

9. Listed nominal capacities are based on using 33mil (20ga) non-structural framing members/studs.

Bend center tab along slotted holes inward to lay flush against outer face of metal stud web when installed. On the other end of the Backer Bar, bend small tabs along slotted holes outward to lay flush against inner face of metal stud web when installed. Secure the Backer Bar to the metal studs with (5) #8 wafer head/pan head screws at pre-punched holes in to flange of stud.

Code Approvals & Performance Standards

- AISI S100-16 (2020) w/S2-20 North American Specification for the Design of Cold-Formed Steel Structural Members

- SDS For ASTM A1003 Steel Framing Products For Interior Framing, Exterior Framing and Clips/Accessories

CAD Details

Note: to view all of ClarkDietrich's CAD details, visit the CAD Details Library.

PRoduct submittal SHeets

Click the below Product Code to view Submittal/Tech Datasheet.

| Product Code | Description |

|---|---|

| Backer Bar | Backer Bar |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

- Clip Express Sales at 866-638-1908 or clipexpress@clarkdietrich.com

- Technical Support at 888-437-3244 or support@clarkdietrich.com