Eliminates the header track material and is a more economical alternative

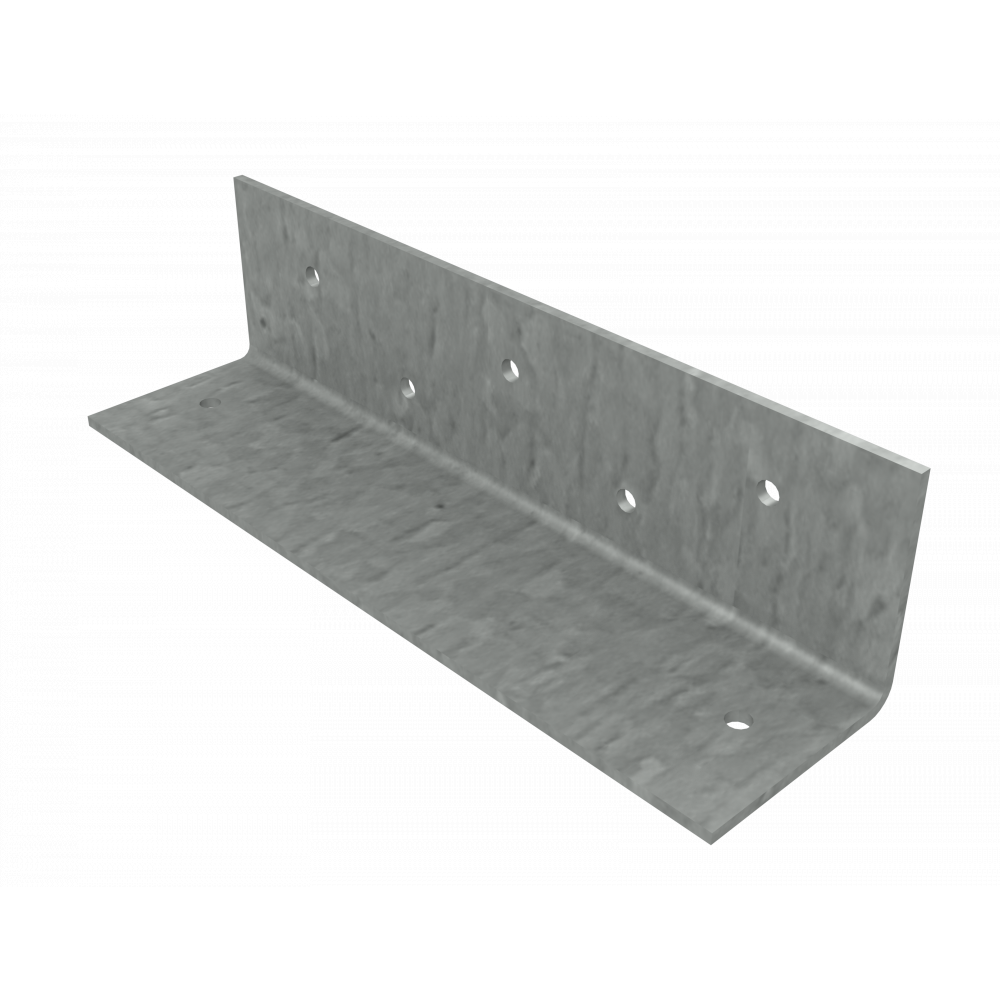

Application(s): Header Connection, Base Connection

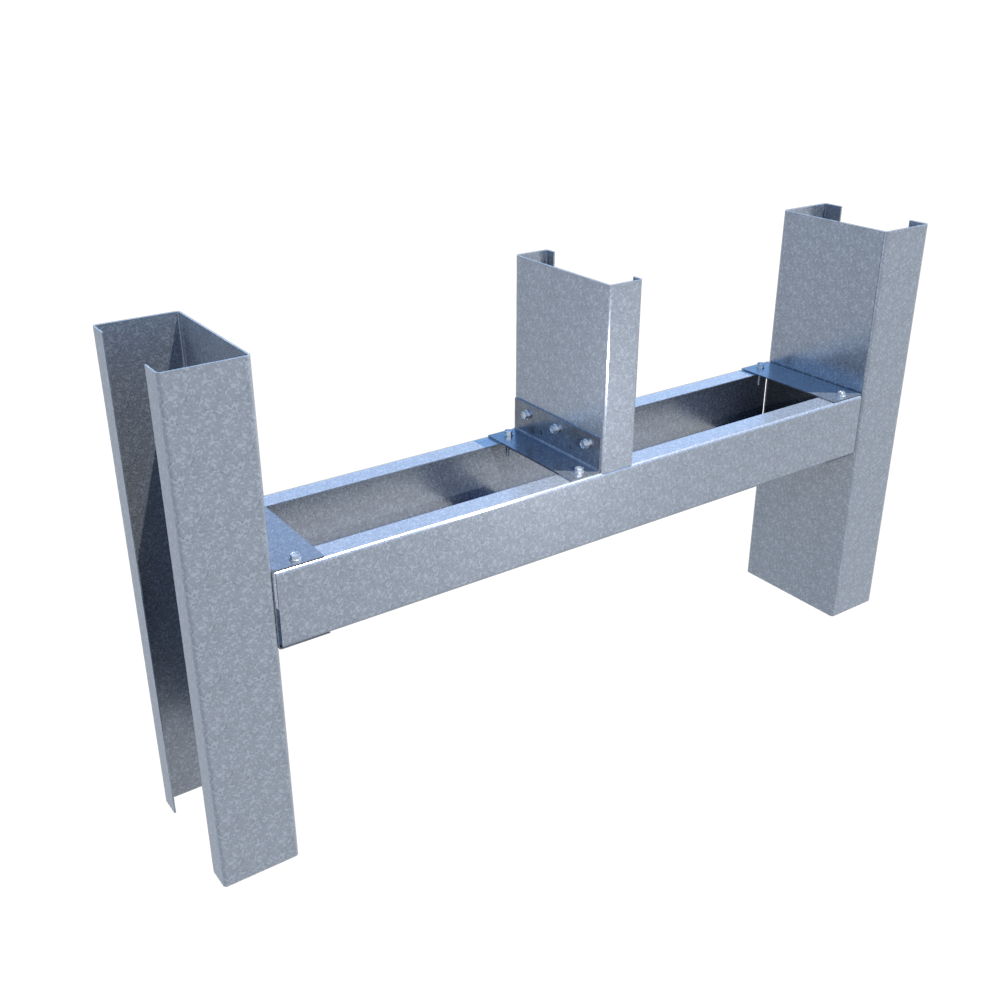

Why use a header Cripple Stud Clip with the RedHeader PRO or HDS Framing System?

- Eliminates the header track material and is a more economical alternative

- Extra long return legs on RedHeader PRO and HDS allows for ease of attachment

- Top of header is open, allowing for easy install of the insulation. No need to "pre-insulate" headers prior to installation

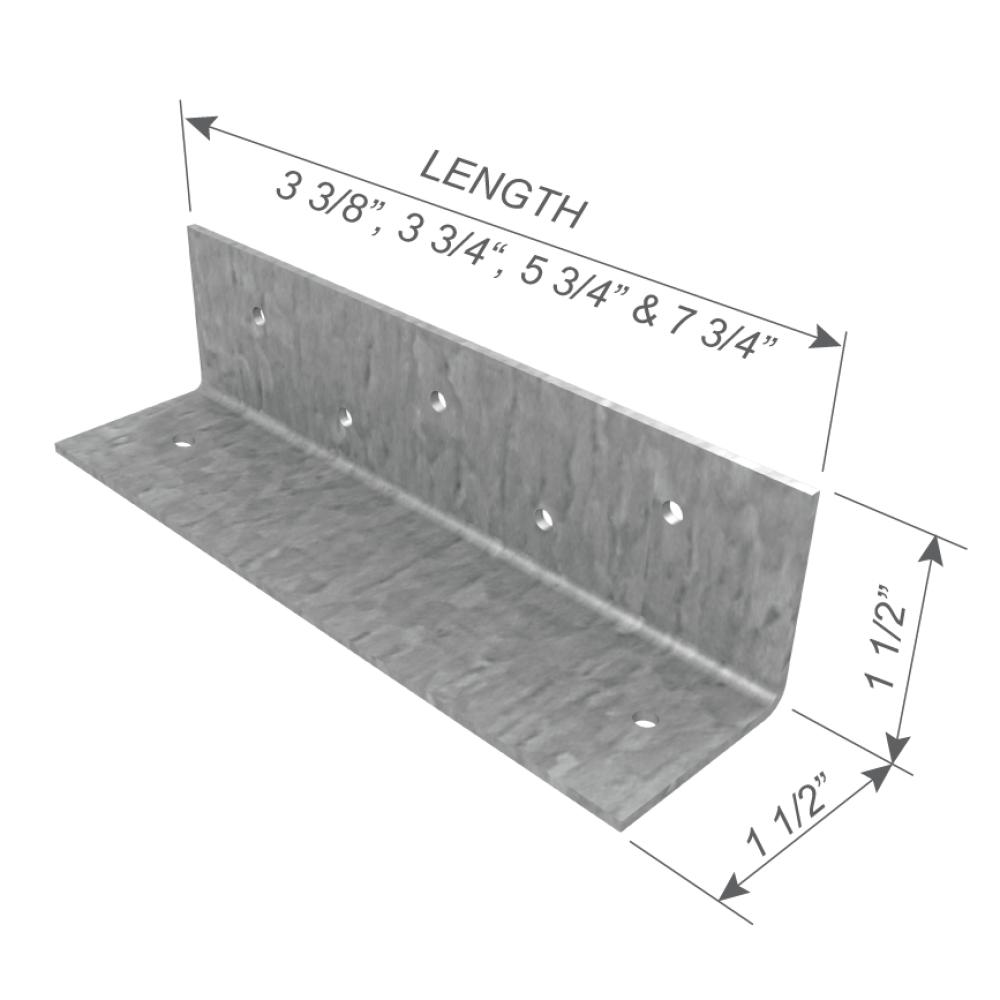

- Lengths available in 3-3/8", 3-3/4", 5-3/4", and 7-3/4"

- Available in 16 and 14 gauge

- Clip Express Sales at 866-638-1908 or clipexpress@clarkdietrich.com

- Technical Support at 888-437-3244 or support@clarkdietrich.com

Product Data & Ordering Information

| Product code | Gauge | Mils | Design thickness (in) | Size (in) | For Header Size | Pcs./Bucket |

|---|---|---|---|---|---|---|

| RCSC3-54 | 16 | 54 | 0.0566" | 1-1/2" x 1-1/2" x 3-3/8" | 3-5/8" Web | 400 |

| RCSC4-54 | 1-1/2" x 1-1/2" x 3-3/4" | 4" Web | 200 | |||

| RCSC6-54 | 1-1/2" x 1-1/2" x 5-3/4" | 6" Web | 100 | |||

| RCSC8-54 | 1-1/2" x 1-1/2" x 7-3/4" | 8" Web | 100 | |||

| RCSC3-68 | 14 | 68 | 0.0713" | 1-1/2" x 1-1/2" x 3-3/8" | 3-5/8" Web | 200 |

| RCSC4-68 | 1-1/2" x 1-1/2" x 3-3/4" | 4" Web | 200 | |||

| RCSC6-68 | 1-1/2" x 1-1/2" x 5-3/4" | 6" Web | 100 | |||

| RCSC8-68 | 1-1/2" x 1-1/2" x 7-3/4" | 8" Web | 100 |

Material Structural Grade 50 Type H (ST50H), 50ksi

Coating G90 (Z275) hot-dipped galvanized coating

INSTALLATION

- Header Cripple Stud Clips are attached to the cold-formed steel (CFS) framing members using #10 minimum self-drilling screws driven through the clip holes into the steel framing.

- It is the responsibility of the design engineer to detail the attachment of clips and verify their capacity meets the application.

- Place the first two screws in each leg in the outermost screw holes. The next screws (if needed) are placed moving from the outermost holes toward the center, symmetrically.

Code Approvals & Performance Standards

- AISI S100-16 (2020) w/S2-20 North American Specification for the Design of Cold-Formed Steel Structural Members

- AISI S240-20 North American Standard for Cold-Formed Steel Structural Framing

- (Compliant to ASTM C955, but IBC replaced with AISI S200 in IBC 2015, AISI S240 in IBC 2018)

- Section A3 Material - Chemical & mechanical requirements (Referencing ASTM A1003/A1003M)

- Section A4 Corrosion Protection (Referencing ASTM A653/A653M)

- Section C Installation - (Referencing ASTM C1007)

- SDS For ASTM A1003 Steel Framing Products For Interior Framing, Exterior Framing and Clips/Accessories

CAD Details

Note: to view all of ClarkDietrich's CAD details, visit the CAD Details Library.

Product Submittal Sheets

Click the below Product Code to view Submittal/Tech Datasheet.

| Product code | Gauge | Mils | Size (in) | For Header Size |

|---|---|---|---|---|

| RCSC3-54 | 16 | 54 | 1-1/2" x 1-1/2" x 3-3/8" | 3-5/8" Web |

| RCSC4-54 | 1-1/2" x 1-1/2" x 3-3/4" | 4" Web | ||

| RCSC6-54 | 1-1/2" x 1-1/2" x 5-3/4" | 6" Web | ||

| RCSC8-54 | 1-1/2" x 1-1/2" x 7-3/4" | 8" Web | ||

| RCSC3-68 | 14 | 68 | 1-1/2" x 1-1/2" x 3-3/8" | 3-5/8" Web |

| RCSC4-68 | 1-1/2" x 1-1/2" x 3-3/4" | 4" Web | ||

| RCSC6-68 | 1-1/2" x 1-1/2" x 5-3/4" | 6" Web | ||

| RCSC8-68 | 1-1/2" x 1-1/2" x 7-3/4" | 8" Web |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System

- Clip Express Sales at 866-638-1908 or clipexpress@clarkdietrich.com

- Technical Support at 888-437-3244 or support@clarkdietrich.com