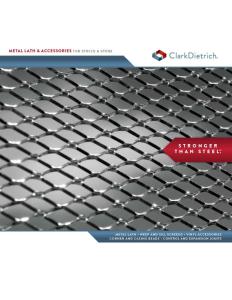

heavy duty Reinforcing

Mega Lath is a self-furring welded wire that provides heavy-duty reinforcing for both stucco and stone installation.

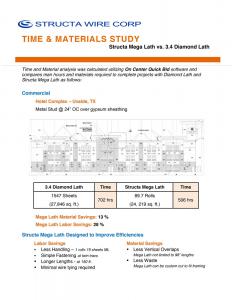

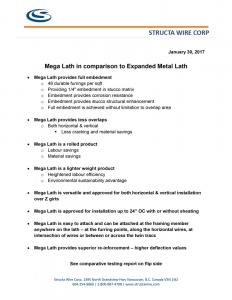

Mega Lath is an engineered product that provides easy attachment for both wood and steel construction. Specifically designed for stucco applications that require extra reinforcing, Mega Lath can be used as an alternative to 3.4 lb/yd2 diamond mesh metal lath specified in ASTM C847 and at 1.95 lb/yd2, Mega Lath can be installed 24" o.c. over open framing. Mega Lath is recommended wherever 2.5 lb/yd2 or 3.4 lb/yd2 metal sheet lath is specified.

Find out more about Structa Wire here

NEW INNOVATIVE PRODUCT

- Mega Lath is made with less metal but has more strength than any other product available – including sheet lath products

- It is engineered to meet weight requirements for architectural stone product installations

DESIGN FEATURES

- Dense product is made from 16ga X 17ga galvanized steel wire welded to form 11/16" x 1.5" openings

- Its design promotes uniform plaster thickness

- A series of flat-bottomed V-shaped furrs ensure a full 3/8" scratch coat

- Furr will not puncture the vapour barrier

- Additional cold-rolled longitudinal wires form a twin track that simplifies attachment, for greater productivity and job satisfaction

- The cold-rolled technology produces flat wires that reduce curvature memory, for an easy-to-handle roll

- Rolls are more manageable than sheet products and make for easy installation

- MegaLath is also available in stainless steel. Click here for a submittal

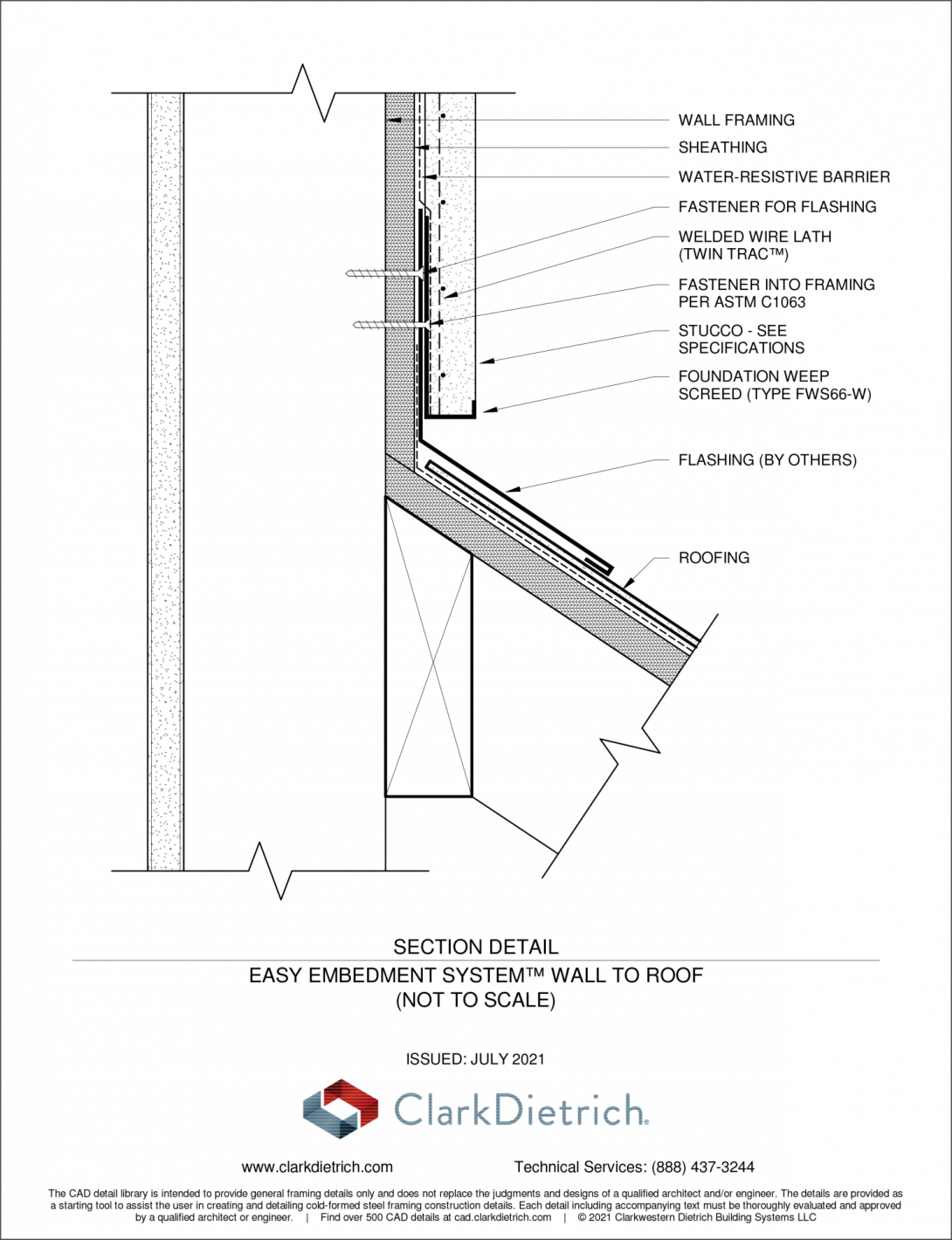

MEGALATH IS PART OF ClarkDietrich's EASY EMBEDMENT SYSTEM (EES)

FOR SALES AND TECHNICAL QUESTIONS:

- East Coast to Texas: (800) 543-7140

- West of Texas to California: (800) 887-4708

Stracta Lath Installation Tips

Brief description of how to install Stucta-Wire Lath for use in Stucco and Thin Stone Applications

Easy Embedment System (EES) Overview

Downloadable CAD details are available in the Resources tab

ClarkDietrich Embedment Video White Paper

Stucco embedment is critical to providing enduring cladding performance on a building’s plaster/stucco walls. Embedment is a function of application whereby the lathing material is covered by the plaster. The greater the level of embedment, the less likely the wall system is to be faced with cracking, moisture penetration, rusting, and other issues. This white paper will discuss several considerations around different attributes of lathing products and their effect on embedment.

Documents

Code Approvals & Performance Standards

- ASTM A641 Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire

- ASTM C933 Standard Specification for Welded Wire Lath

- ASTM C1063 Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster

- ASTM C1780 Standard Practice for Installation Methods for Cement-based Adhered Masonry Veneer

- ASTM E119 Standard Test Methods for Fire Tests of Building Construction and Materials

- For concrete substrates only - contact ClarkDietrich Technical Services for results.

- DSA / California IR 25-4 Self-furring Lath

- IAPMO ER-2017 Metal Lath

- SDS StructaWire for StructaWire products

Specifications & Substitution Forms

To simplify the Product Substitution Request process when Structa Wire or ClarkDietrich’s products are not listed in the Architectural Specification, see our CSI Substitution Request Forms to help streamline the procedure.

CAD Details

Note: to view all of ClarkDietrich's CAD details, visit the CAD Details Library.

PRoduct submittal SHeets

Click the below Product Code to view Submittal/Tech Datasheet.

| Product code | Description |

|---|---|

| Mega Lath | Mega Lath 3.4# |

| Mega Lath-SS | Mega Lath 3.4# - Stainless Steel |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about creating product submittals or using SubmittalPro.