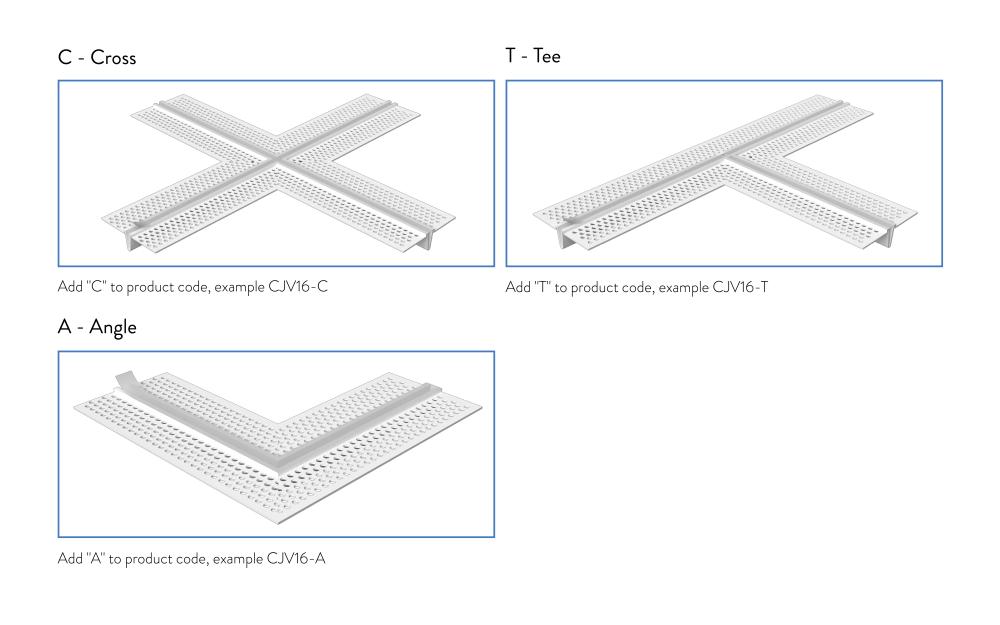

Control joint intersections are manufactured in a controlled factory environment to the highest quality standards

Miter cuts are made with precision to ensure proper fit at all connections.

All ClarkDietrich control joint intersections are manufactured in a controlled factory environment to the highest quality standards. Miter cuts are made with precision to ensure proper fit at all connections. Hot-melt glue and foil-backed tape are used to create a strong bond for all components. The quality of ClarkDietrich's fabricated control joint intersections cannot be duplicated on a job site.

It is recommended that additional 10ft. control joint material is ordered along with all intersections to ensure seamless connections. Caulk all intersections, butt joints, ends and corners at time of installation. All factory fabricated control joint intersections are made-to-order.

All factory fabricated intersections are made-to-order. Please contact us at 1-800-648-4695 for specific lead-times and capabilities on any special intersections.

Code Approvals & Performance Standards

- ASTM C840 Standard Specification for Application and Finishing of Gypsum Board

- ASTM C841 Standard Specification for Installation of Interior Lathing and Furring

- ASTM C1047 Standard Specification for Accessories for Gypsum Wallboard and Gypsum Veneer Base

- ASTM D3678 Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) Interior - Profile Extrusions

- SDS Vinyl Corp PVC Compounds

Storage:

All stored materials shall be kept dry. Materials shall be stacked off the ground, supported on a level platform, and protected from the weather.