REDUCE STEEL STUD BACKING Labor costs BY UP TO 75%

Danback® Flexible Wood Backing System, featuring D-Blaze® or FlamePRO® fire-retardant treated wood (FRT), has made wood backing installation easy and economical-eliminating cutting, notching, ripping and routing.

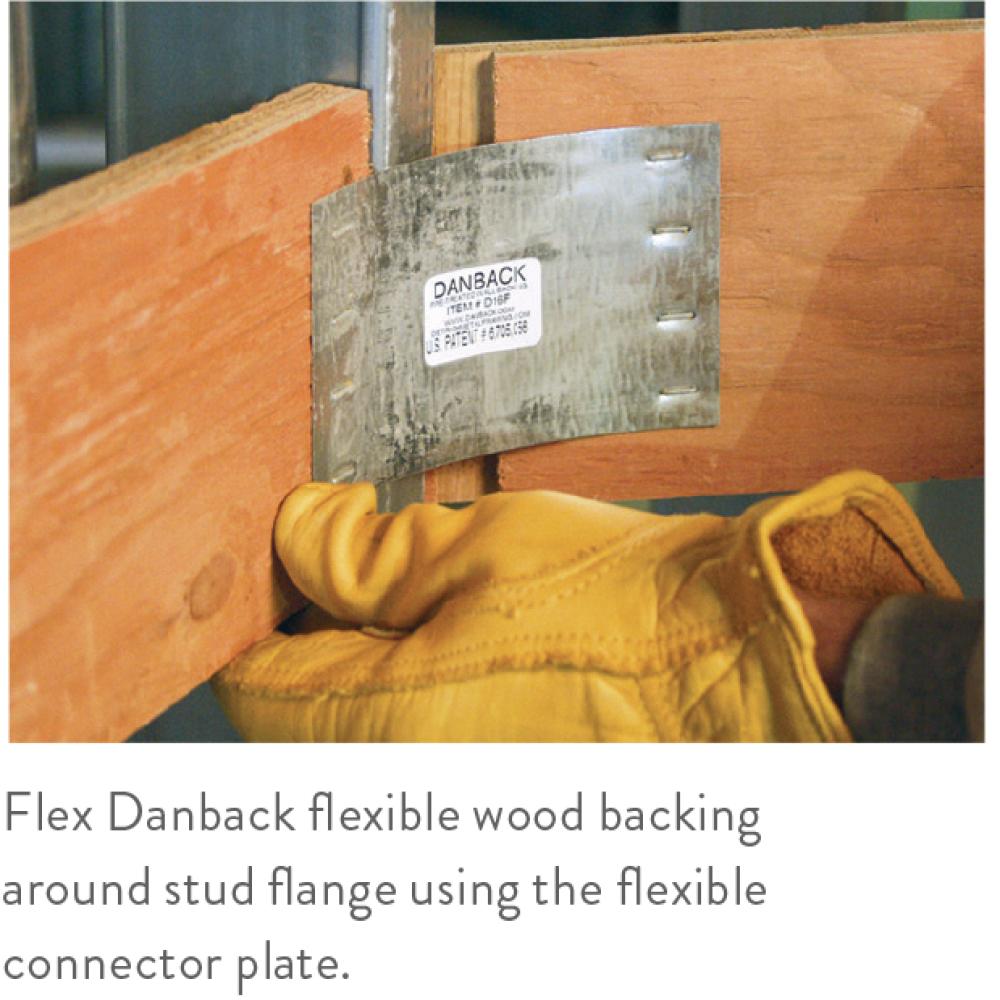

Danback provides superior connection shear and pullout strength to support and meet even some of the heaviest loading conditions. Simply snap, flex and screw Danback into place. The patented hinge design actually flexes around the stud and snaps into place for a perfect fit-every time.

- Provides extra screw pullout strength for heavy-duty backing applications

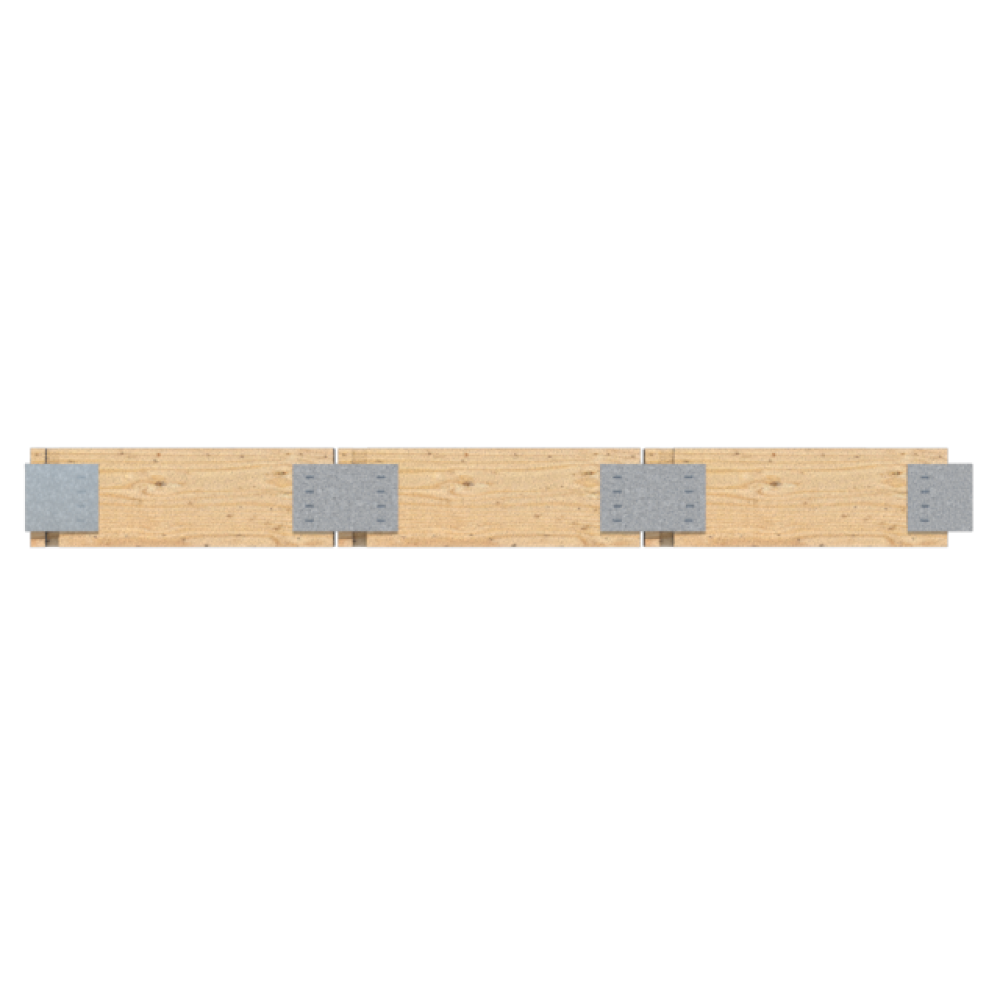

- Available in 48” sections, for either 16“ or 24” on-center framing

- Meets all specifications for commercial and residential applications

Perfect backing system for:

- Handrails

- Baseboards

- Door Jambs and Wood Trim

- Cabinets and Vanities

- Ceiling and Crown Moldings

Wood Backing is fire retardant, pressure-treated wood that is chemically treated to reduce flamespread and smoke development. Fire retardant wood is Class A fire retardant ; EPA registered, and complies with all national codes including the International Building Code (IBC) and the International Residential Code (IRC). Evaluation Report Service found that the wood backing material complies with requirements for fire retardant treated wood described in the International Building Codes (IBC & IRC).

Danback flexible wood backing is available with FSC®-certified lumber and may contribute LEED® points to your project.

U.S. Patent No. 6,705,056 of Daniel W. Tollenaar

Danback® is a trademark of Daniel W. Tollenaar.

D-Blaze® is a registered trademark of Viance, LLC.

FlamePRO® is a registered trademark of Koppers Performance Chemicals, Inc.

Product Data & Ordering Information:

| Product code | Width | Length | Spacing | Pcs./Skid |

|---|---|---|---|---|

| D16F* | 5-1/8" | 48" | 16" o.c. | 250 |

| D24F* | 5-1/8" | 48" | 24" o.c. | 250 |

| D16C** | 5-1/8" | 48" | 16" o.c. | 250 |

| D24C** | 5-1/8" | 48" | 24" o.c. | 250 |

* = fire-treated plywood.

** = FSC-certified lumber available on request, which can contribute to LEED® points on your project. Contact ClarkDietrich LEED professionals at 888-437-3244 for more information. FSC chain-of-custody # BV-COC-008121

Trimmables available for off-module spacing in bulk quantity.

Material: 3/4" CDX Doug Fir D-Blaze® or FlamePRO® fire-retardant treated wood

Dimensions: 5-1/8" x 48" (130mm x 1219mm)

Packaging: (250) pieces per skid

Product weight: 5.114 lbs. / piece

- Clip Express Sales at 866-638-1908 or clipexpress@clarkdietrich.com

- Technical Support at 888-437-3244 or support@clarkdietrich.com

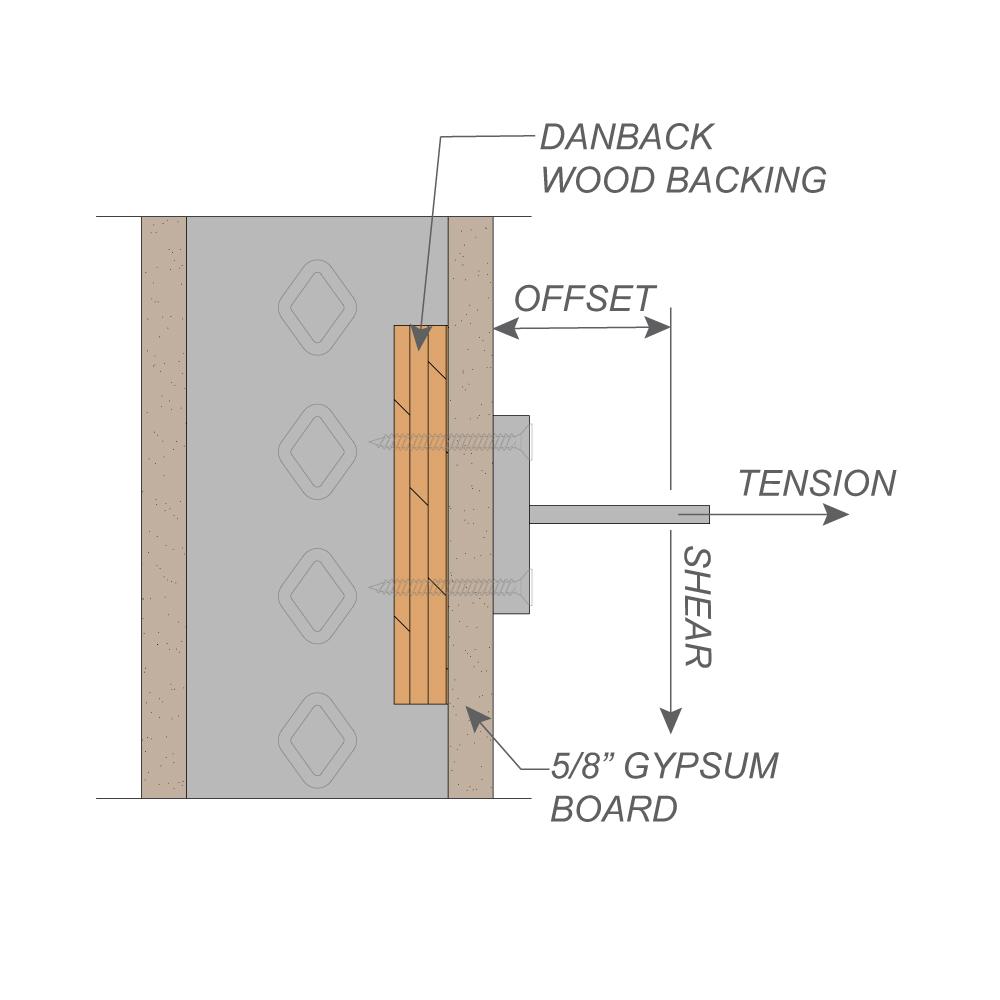

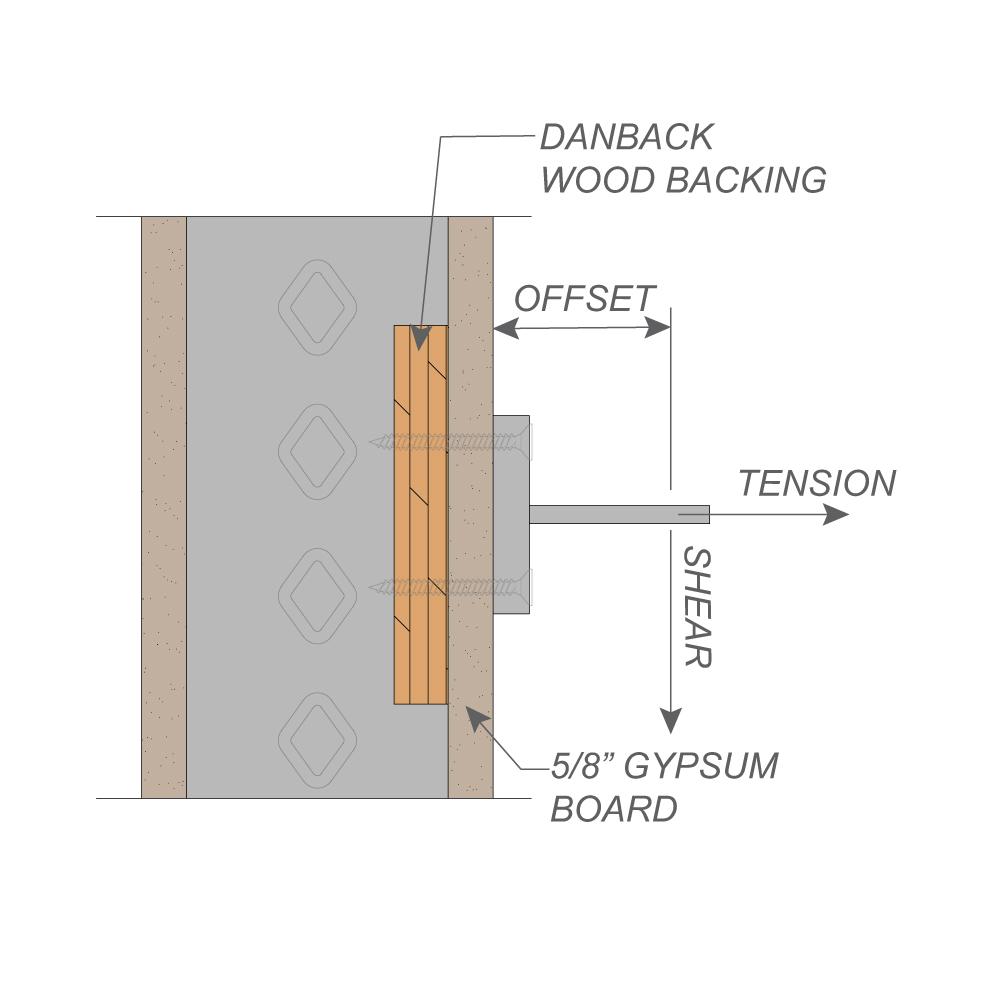

Load Tables

| INSTALLATION CONDITION | NOMINAL (LBS) |

|---|---|

| Shear / 0" Offset | 2440 |

| Shear / 1" Offset | 825 |

| Shear / 3" Offset | 310 |

| Tension | 635 |

Notes:

1. Listed load values are nominal test load values, appropriate safety factors/resistance factors should be applied by the designer for calculating loads for intended use.

2. Shear / Offset (moment-rotation) Load refers to load directed in the plane of the wall.

3. Tension Load refers to load directed perpendicular to wall or plywood surface.

4. Tabulated loads include the contribution of 5/8" gypsum board.

5. Test loads were applied to the gypsum board and backing system through a 1/2" thick, 2-3/4" diameter steel plate secured with (4) #12 hex head screws.

6. Loads were applied directly through the steel plate or to a steel rod that cantilevered from the plate.

7. Typical failure mode in backing testing was the gypsum board failure.

8. 24-in o.c. stud spacing test results were similar/identical to 16-in o.c. test results.

9. Listed nominal capacities are based on using 33mil (20ga) non-structural framing members/studs.

10. Anchor to the stud flange using (3) #8 wafer head/pan head screws.

INSTALLATION:

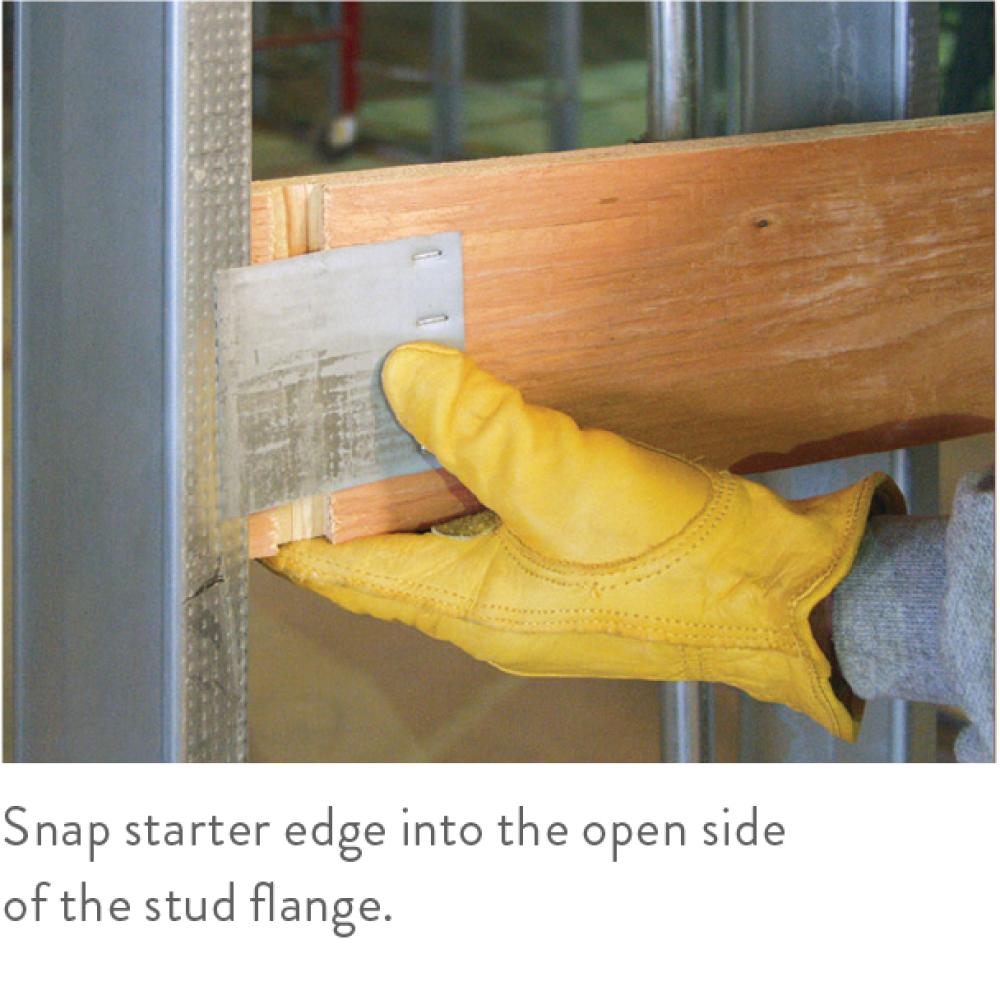

- Snap starter edge into the open side of the stud flange.

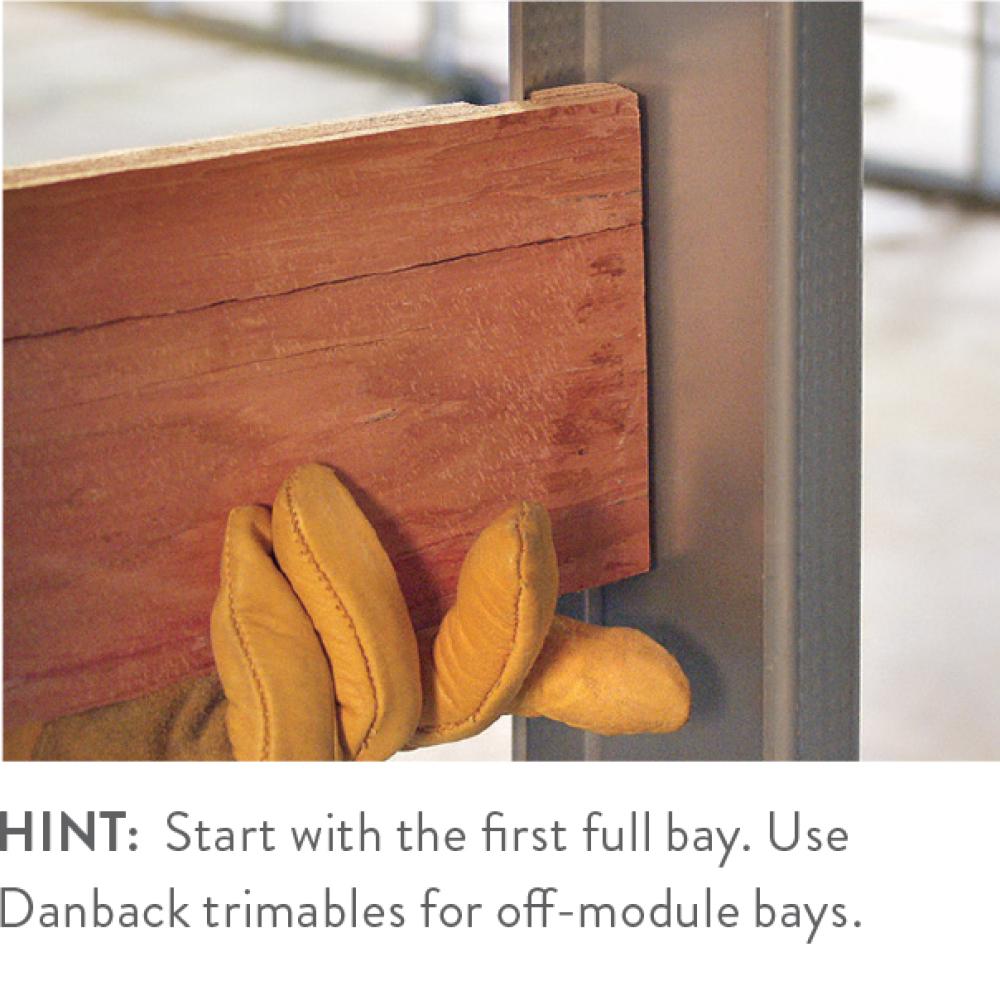

- Hint: Start with the first full bay. Use Danback Trimmables for off-module bays.

- Flex Danback flexible wood backing around stud flange using the flexible connector plate.

- Repeat the process.

- Overlap connector plates when using in long backing runs.

- Secure each plate to the stud flange using (3) #8 wafer head/pan head screws. Place one screw at the center and one screw 1/2" from top and bottom of the plate edge.

DanBack Catalog Pages and Installation Guide

Code Approvals & Performance Standards

- AISI S100-16 (2020) w/S2-20 North American Specification for the Design of Cold-Formed Steel Structural Members

- FRT D-Blaze Performance Standards for Fire Retardant Treated Wood

- FRT FlamePRO Performance Standards for Fire Retardant Treated Wood

- SDS Danback Flexible Wood Backing

CAD Details

Note: to view all of ClarkDietrich's CAD details, visit the CAD Details Library.

PRoduct submittal SHeets

Click the below Product Code to view Submittal/Tech Datasheet.

| Product Code | Description |

|---|---|

| D16F, D24F | Danback Flexible Wood Backing |

| D16C, D24C (FSC) | Danback Flexible Wood Backing (FSC Wood) |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

- Clip Express Sales at 866-638-1908 or clipexpress@clarkdietrich.com

- Technical Support at 888-437-3244 or support@clarkdietrich.com