In 2016, a large-scale residential development outside Orlando faced what became a multimillion-dollar remediation. The culprit? Stucco, according to the legal filings. Homeowners cited cracking façades, staining, and water leaks. Within months, siding crews had to replace entire elevations with fiber cement board, and developers across the region took note.

.jpeg)

But here’s the thing: the stucco itself wasn’t the problem.

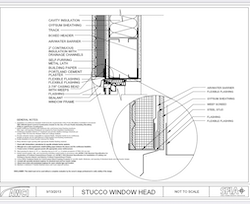

An investigation revealed misaligned control joints, missing weep screeds, and poor window flashing—mistakes that any building envelope system would struggle to overcome. This wasn’t a material failure. It was a detailing failure.

And yet, the perception stuck. Today in Florida and other markets in the southeast and west coast, stucco is being edged out by siding systems—vinyl, fiber cement, or composite panels. Builders cite liability concerns and performance issues. But as professionals in the wall and ceiling trade know, cladding systems don’t fail. Assemblies do. And more often than not, it’s the details that make or break the wall.

Stucco

Stucco is a tried-and-true cladding system, valued for centuries across a wide range of architectural styles—from Mediterranean villas to Southwestern adobe homes and modernist façades. Its enduring appeal lies in its versatility, durability, and ability to provide a seamless, weather-resistant exterior. When properly installed, stucco offers excellent thermal performance, natural fire resistance, and protection against insects and moisture. Beyond function, it is also an artful finish, adaptable to both smooth and textured aesthetics, making it a favorite among architects and builders seeking both performance and timeless visual impact.

Yet, its market share is shrinking. Builders are opting for materials perceived to be “easier” or “safer,” especially in light of mounting litigation tied to improper stucco installs. But siding systems are not immune. Failures with vinyl and cementitious panels—buckling, delamination, trapped moisture, and mold—have also surged.

The common thread? Not the material, but the missed details.

What fails?

Most wall system issues trace back to five key failure points. These include improperly flashed windows and doors, poor transitions at parapets or decks, missing or misused WRBs, inadequate drainage planes, and the absence of control joints.

Stucco gets a bad rap because its failures are visible—cracks, stains, delamination. But the same core issues apply to siding: hidden water behind lap joints, rot in OSB sheathing, or distorted cladding under sun and moisture stress.

In all cases, it’s the “invisible work” behind the surface that determines longevity.

Far from outdated, stucco over wood, steel, and masonry block—with proper lath and reinforcement—remains one of the most robust cladding systems available.

Performance-based lathing products are engineered to ensure full stucco embedment and provide crack resistance and material consistency. When these systems are installed to spec—with appropriate control joints, flashing, and finish tolerances—stucco outperforms many newer materials on the market.

Plus, it delivers:

- A thermal buffer

- Fewer seams and joints than siding systems

- Architectural versatility, from knockdown and sand finishes to sharp modern smooth finishes

Craftsmanship

What’s really at stake isn’t just market share—it’s craftsmanship. In the race to reduce costs and compress schedules, we’ve seen a shift away from highly trained plasterers to “all-trade” siding installers, even for stucco assemblies.

That’s a risky bet.

True plasterers understand the sequencing, joint placement, curing times, and layering that make stucco last. When you lose that knowledge, you lose the reliability of the system. And, unfortunately, the industry is now paying the price.

Time to Reclaim the Narrative

The trades that support lath, plaster, and traditional wall systems have an opportunity—and responsibility—to reclaim stucco’s reputation.

That means:

- Educating builders on best practices and clear scopes of work

- Collaborating with architects to ensure detail clarity at openings and transitions

- Investing in training and quality control, especially for multi-family and high-volume developments

- Avoiding value engineering that removes critical components

Because no material can succeed when the envelope around it is ignored or poorly executed.

.jpg)

Build Better—Don’t Blame the Cladding

Stucco isn’t going anywhere. Its value in the built environment is time-tested, thermally resilient, and architecturally rich. But its continued success depends on one thing: doing it right.

If we want walls that last—with fewer callbacks—we need to stop pointing fingers at the finish coat and start focusing on the craft behind it. In this industry, the system is the sum of its details.