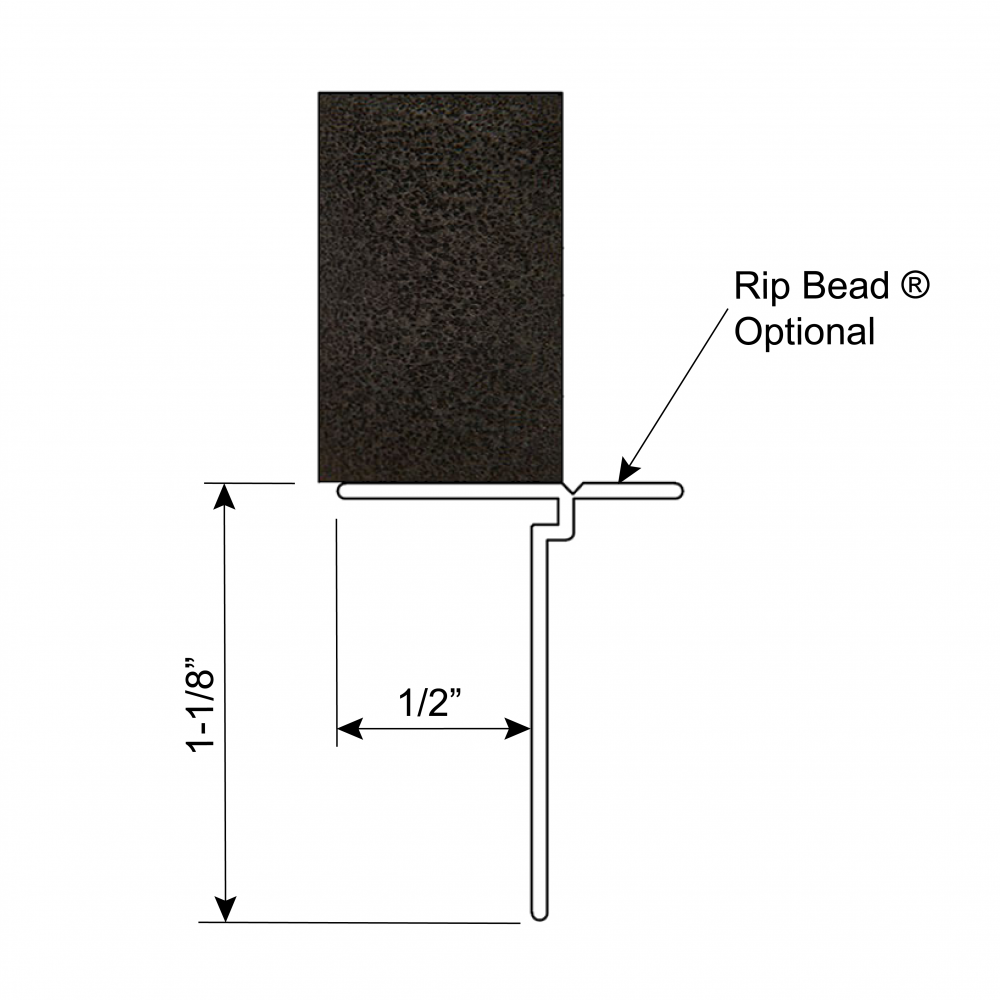

VINYL L-Bead with Compressible Foam

Creates an easy attachment that is attained with staples through the bead flange.

BlazeFrame® Perimeter L-Bead creates an easy attachment that is attained with staples through the bead flange. Multiple perforations along the 1-1/8" flange enhance strong compound adhesion and the raised shoulder provides for a flush finish. Rigid vinyl is rust proof, dent resistant and easy to field cut without distorting profile or leaving sharp edges and burrs.

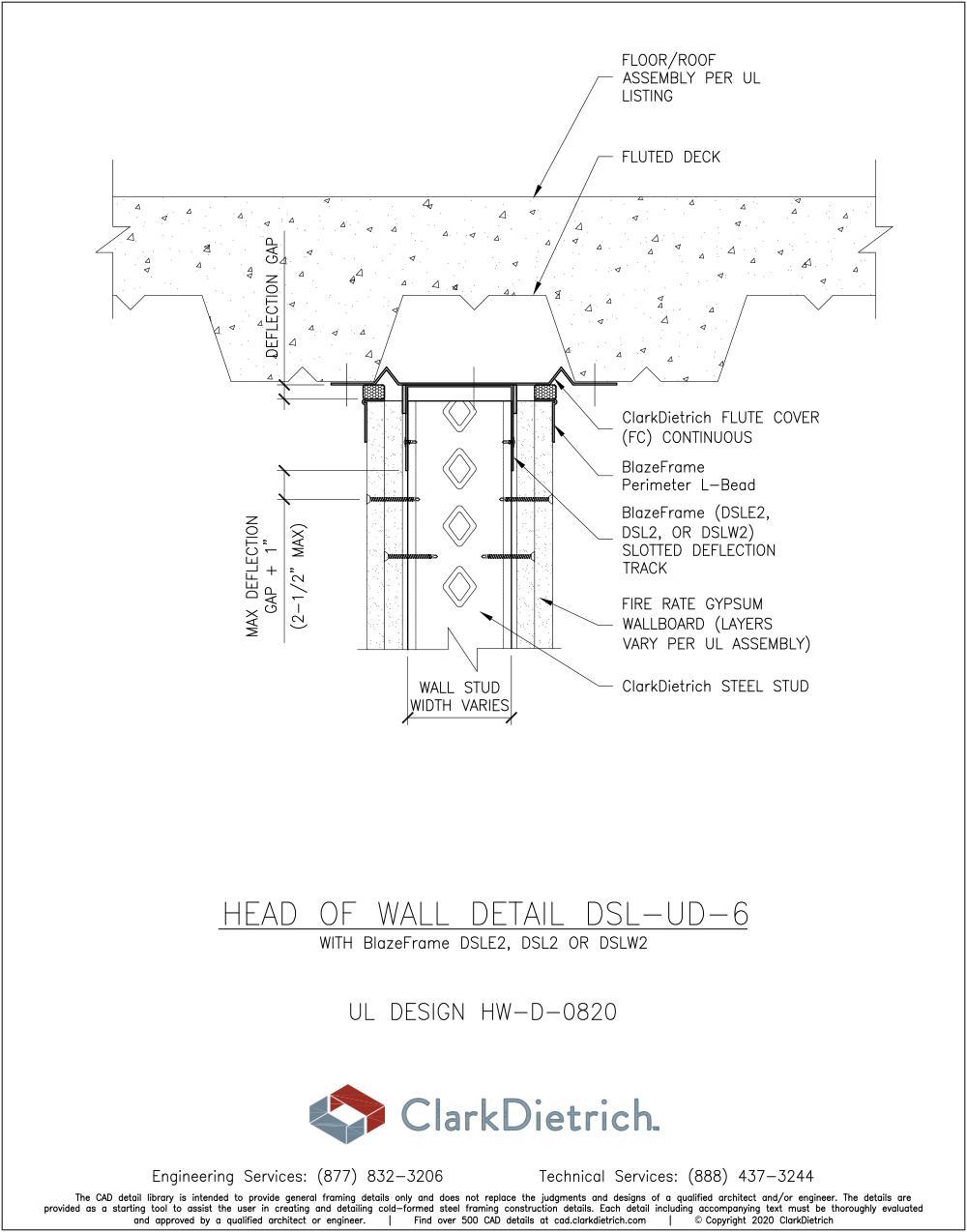

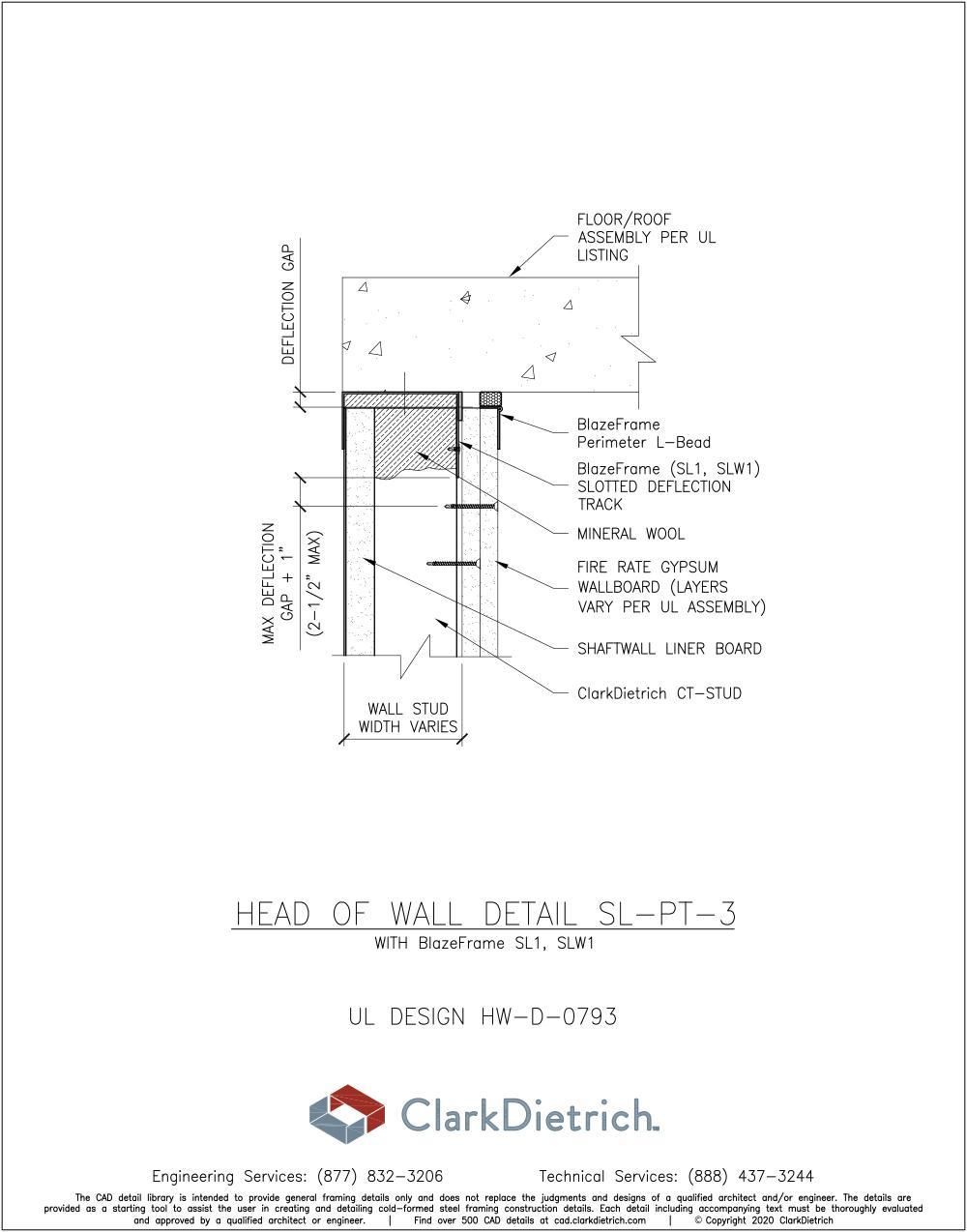

Composite Firestop/Framing for use in fire-resistant joint systems in or between fire-resistance-rated walls and floor/ceiling or roof/ceiling assemblies. Many assemblies can also be used in smoke barriers with tested air leakage (L ratings) well below the code defined maximum of 5 cfm per linear foot.

When used in conjunction with BlazeFrame Fire Stop Deflection Track Systems, BlazeFrame Perimeter L-Bead is UL 2079-fifth edition compliant. Provides joint protection for up to 1" with UL 2079 Class II or III Movement Capabilities at 80% compression.

U.S. Patent Number 11,725,401 and 11,486,150 on Perimeter L-Bead.

Product Data & Ordering Information:

| Profile | Width | Lenth | Wt./Ctn. | Pcs./Ctn. |

|---|---|---|---|---|

| Perimeter L-Bead | 1/2" | 8' | 24 lbs | 40 |

| Perimeter L-Bead with Rip Bead® | 1/2" | 8' | 18 lbs | 30 |

Vinyl Material: 0.028" PVC (Polyvinyl Chloride)

L-Bead Dimensions: 1/2" Leg x 1-1/8" Flange (available in rip bead)

Length: 8'-0"

Vinyl color: White

Foam color: Black

Sound Testing

Fire Rated Assembly

- UL File Number R26034-XHHW Full list of BlazeFrame UL design assemblies

Need help with making the best product selections for your Fire-Rated Project?

- Submit info to our Technical Services Representatives to help answer your questions.

Installation

- Cut to length with a fine-toothed hacksaw or chop saw

- Make sure to cut ends square

- Compress the foam and slide the horizontal leg over the top edge of the gypsum board

- Ensure the horizontal flange and vertical flange are in contact with the gypsum board.

- Attach perforated vertical flange to the gypsum base with Bostich 9/16" type G staples, or equivalent, spaced 12" on center maximum

- Repeat steps #1 and #2 and then butt together and align to provide a neat tight fit, with no gaps between the vinyl or foam.

- Repeat until all joints have been filled with the BlazeFrame Perimeter L-Bead

- Apply joint compound to perforated leg (optional)

- May be painted with high grade latex or acrylic paint (optional)

Storage:

All stored materials shall be kept dry. Materials shall be stacked off the ground, supported on a level platform, and protected from the weather.

Code Approvals & Performance Standards

- ASTM C840 Standard Specification for Application and Finishing of Gypsum Board

- ASTM C1047 Standard Specification for Accessories for Gypsum Wallboard and Gypsum Veneer Base

- ASTM D1056 Standard Specification for Flexible Cellular Materials - Sponge or Expanded Rubber

- UL Designs 2079 Fifth Edition Tests for Fire Resistance of Building Joint Systems

- (When used in conjunction with BlazeFrame Firestop Deflection Track systems)

- IBC requires fire-resistant joint systems be tested in accordance w/the requirements of either ASTM E1966 or UL 2079.

- SDS Armacell Ensolite Foam Bead for Perimeter L-Bead

- SDS Vinyl Corp PVC Compounds

-

Need help with making the best product selections for your Fire-Rated Project?

-

Submit info to our Technical Services Representatives to help answer your questions.

CAD Details

Note: to view all of ClarkDietrich's CAD details, visit the CAD Details Library.

PRoduct submittal SHeets

Click the below Product Code to view Submittal/Tech Datasheet.

| PN# | Description |

|---|---|

| 62562 | BlazeFrame® Perimeter L-Bead |

| 62564 | BlazeFrame® Perimeter L-Bead with Rip Bead® |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about creating product submittals or using SubmittalPro.