When designing an exterior plaster system, often the focus is on colors, textures, and finishes. While these aesthetic features can be created with hard-coat plaster, they don’t address the cladding system’s ability to prevent water intrusion and moisture damage to the building.

A stucco cladding system encompasses much more than the finishing material itself, including weather barriers, flashings, control joints and lath material. In order to ensure the full system performs as it should, it is important to understand how the lathing system will interact with the stucco, particularly the lath’s ability to be embedded by the material.

There are several different metal lath materials available on the market today. Here are some of the most commonly used materials and their pros and cons.

Diamond Mesh Lath

Diamond mesh lath typically comes in sheets or rolls and includes diamond-shaped openings formed by the intersecting metal wires. The lath itself is typically made from galvanized metal, which provides corrosion resistance and durability.

Though building codes dictate the specification of sheet lath by weight, the size of these diamond openings is not standardized. Opening sizes vary but are typically around 3/8" x 1/2" in length and width.

Because of this variability in opening size, pressing wet plaster through diamond mesh lath can be challenging. Plastering contractors often run their plaster “stiff” (i.e., less water in the stucco mixture or use of fibers) to get better surface contact with the diamonds and to assure adhesion. However, this can make it more difficult to fully push the plaster through the diamonds, thereby reducing the level of embedment. While it is possible to achieve acceptable embedment with diamond mesh lath, the applicator must know precisely how to mix plaster to achieve a stiffness ideal for penetrating the diamond surface.

Another consideration with this type of lath is how it is fastened to the substrate. Expanded metal lath that is over-fastened will restrict the passing of plaster through the diamond-shaped openings in the lath, negatively impacting embedment, especially at the edge joints and laps. Paper-backed lath—where a WRB is glued directly to the diamond mesh—increases the challenge of embedment because the WRB can impede the plaster from spreading through the diamonds to get to the backside of the metal lath.

Diamond mesh lath has historically been the option of choice in the Southeast, Northeast and Midwest because these types of products were manufactured in the eastern U.S. and sheets were installed by multiple trades including plasterers and stone masons. Most all lathing and plastering in these regions is paddle-mixed and troweled directly onto the lath. This “hawk and trowel” application method is often used on smaller projects and requires the trowel operator to be skilled in the placement of wet plaster into and through the lath to create embedment.

Woven Wire Lath

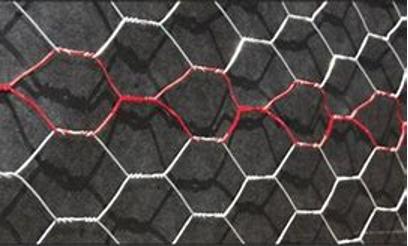

Woven wire offers little furring. The red area is self-furred, but this is often inconsistent.

Unlike expanded metal lath, which is created by cutting and stretching a flat sheet of metal, woven wire lath is made by interweaving wires in a crisscross pattern to form a mesh.

While woven wire has an open design and provides for easier keying and embedment of the scratch-coat, this style faces different challenges—primarily in maintaining uniformity in furring distance from the wall.

Some woven wire lath lacks a self-furring feature in the wire and therefore can’t provide uniform separation from the wall. This means the contractor must create the proper 1/4” furring depth using a special furring nail or furring wad. This inconsistency reduces woven wire’s ability to remain in the center of the scratch-coat. Additionally, over- or under-fastening woven wire lath can restrict its ability to respond appropriately to the pressure of the trowel when applying the scratch-coat. These inconsistencies can result in areas where embedment may not occur.

In Texas and the Mountain states, a hybrid of diamond mesh sheets and woven wire laths makes up most of the market. This is because much of the work is performed by plasterers who use pumps, while others follow the mixing and troweling traditions often used by the stone masons.

Welded Wire Lath

Welded wire lays down evenly with uniform furring.

Welded wire lays down evenly with uniform furring.

Welded wire lath is made by welding together intersecting wires to create a grid-like pattern with uniform openings. The manufacturing process involves welding the wires at their intersections, which makes the lath more rigid and stable compared to woven wire lath. This rigidity makes it easier to handle and install, as the welded points hold the wires securely in place. Because of the stiffness created in the intersecting welds, the wires stay uniform during the scratch-coat process that provides embedment.

Application issues that do arise are seen when wet plaster mix is hand trowel applied during the scratch-coat. A more “wet” scratch-coat can slump off the wire before it can set. On the other hand, a drier mix may cavitate, or not fully pack around the wires, so it’s important to blend a proper water/cement ratio for welded-wire lath applications.

Both welded wire and woven wire lath are popular in the Western and Desert Southwest regions of the U.S., where stucco cladding makes up most of the residential construction and is also used on very large commercial structures. This is because many of the applications in these regions are spray-applied to the lath and troweled into a finish. While both pumping/spraying plaster and hand troweling are allowed by ASTM standards and building codes, pumping/spraying is often preferable for larger projects where volume is needed. This method improves the embedment properties of these types of laths as the spray pressure will penetrate the lath openings.

In general, welded wire lath provides a consistent, evenly furred surface that has openings wide enough to apply a proper plaster mix using the trowel to scratch—then horizontal strokes to smooth in the scratch in preparation for the scoring lines before the brown-coat. This complete scratch-coat base will enhance the brown-coat and ultimately cut down on the number of finish-coat issues.

Welded wire lath is the foundation of ClarkDietrich’s Easy Embedment System™ (EES), which is comprised of Structa Wire and E-Flange™ Casing Beads and Control Joints. Our EES makes stucco embedment fast, efficient, and with less skilled labor required, creating a finish that will stand up over time, reducing callbacks and failures due to moisture intrusion from installations with lesser levels of embedment.

What to learn more? Check out our new video white paper on “The Importance of Embedment in Portland Cement Plaster (Stucco)” here: https://www.youtube.com/watch?v=9w2kSrjV1c4