PVC Control Joint with Embeddable Flange design

Designed to relieve stress and assist in controlling cracking in large areas of walls and ceilings. Specially designed connector clips are provided for alignment and base for sealants.

ClarkDietrich E-Flange™ Control Joint has flanges with more open triangles combined with a raised rib in the center of each flange improving plaster embedment by 80% and provides for easy lath tying to the flange itself. E-Flange allows for more stucco mix to flow through the flange, providing a more thorough and consistent embedment. The unique E-Flange shape also allows for quick and easy tying of lath and other accessories.

Product notes:

- Designed to relieve stress and assist in controlling cracking in large areas of walls and ceilings. Specially designed connector clips are provided for alignment and base for sealants.

- Raised flange height is approximately 3/16"

- Factory fabricated control joint intersections are available in cross, tee and right angle configurations. Contact sales representative for more information.

- U.S. Patent Number D842,497

Product Data & Ordering Information

| Product code | Ground (A) | Flange width (B) | Length | Pcs./Box |

|---|---|---|---|---|

| 1558EF | 5/8" | 1-3/4" | 10' | 30 |

| 1575EF | 3/4" | 1-3/4" | 10' | 26 |

| 1578EF | 7/8" | 1-3/4" | 10' | 20 |

| 15100EF | 1" | 1-3/4" | 10' | 20 |

Lengths: Custom lengths upon request.

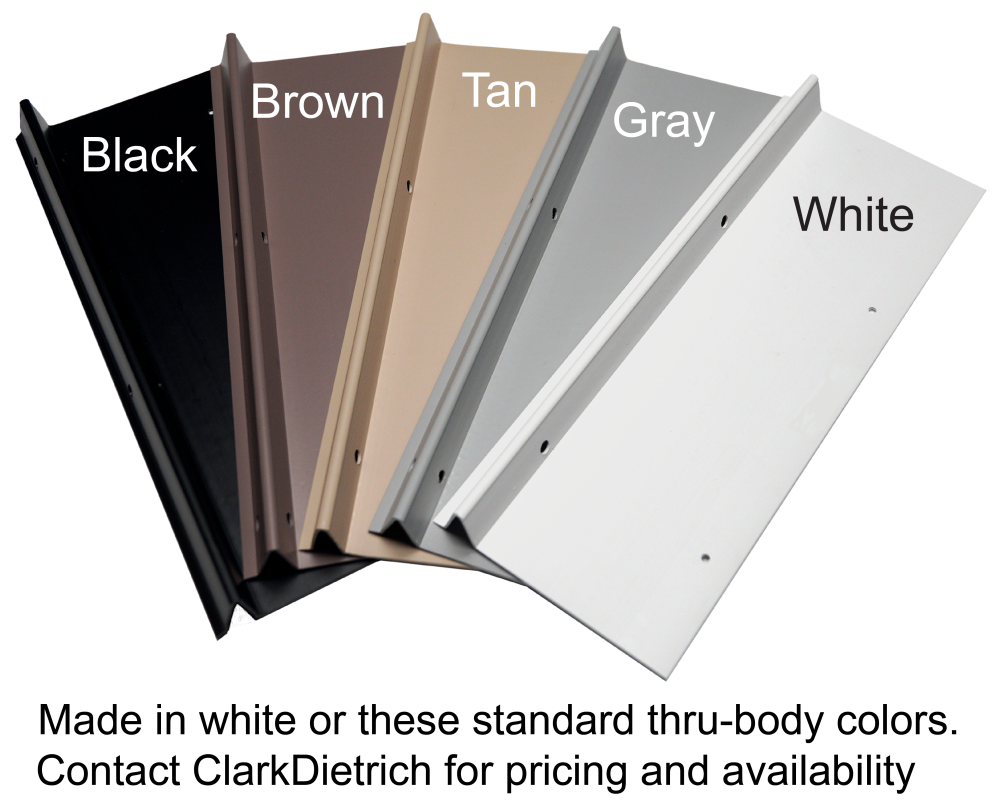

Colors: Available in white (tan/brown/gray available upon request)

Installation:

- Temporarily attach #15 Control Joints to the walls, to establish the pattern for lathing system to merge with.

- Miter-cut all joints and set the into sealant and on the ends of joint. Clean sealant off to remain clean.

- Run all vertical Control Joints continuous, all horizontal joints broken at those intersections only.

- Wire-tie, or zip-tie the Control Joint flange into the lath, as outlined in ASTM C1063. Use rib areas of E-Flange as wire access points.

Downloadable CAD details are available in the Resources tab.

Caulking Instructions

ClarkDietrich Embedment Video White Paper

Stucco embedment is critical to providing enduring cladding performance on a building’s plaster/stucco walls. Embedment is a function of application whereby the lathing material is covered by the plaster. The greater the level of embedment, the less likely the wall system is to be faced with cracking, moisture penetration, rusting, and other issues. This white paper will discuss several considerations around different attributes of lathing products and their effect on embedment.

Code Approvals & Performance Standards

- ASTM C841 Standard Specification for Installation of Interior Lathing and Furring

- ASTM C1063 Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster

- ASTM C1780 Standard Practice for Installation Methods for Cement-based Adhered Masonry Veneer

- ASTM C1861 Standard Specification for Lathing and Furring Accessories, and Fasteners, for Interior and Exterior Portland Cement-Based Plaster

- ASTM D1784 Standard Classification System and Basis for Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds

- ASTM D4216 Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) and Related PVC and Chlorinated Poly(Vinyl Chloride) (CPVC) Building Products Compounds

- SDS Vinyl Corp PVC Compounds

STORAGE

All stored materials shall be kept dry. Materials shall be stacked off the ground, supported on a level platform, and protected from the weather.

CAD Details

Note: to view all of ClarkDietrich's CAD details, visit the CAD Details Library.

PRoduct submittal SHeets

Click the below Product Code to view Submittal/Tech Datasheet.

| Product Code | Description |

|---|---|

| 1558EF, 1575EF, 1578EF, 155100EF | E-Flange™ Control Joint |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about creating product submittals or using SubmittalPro.