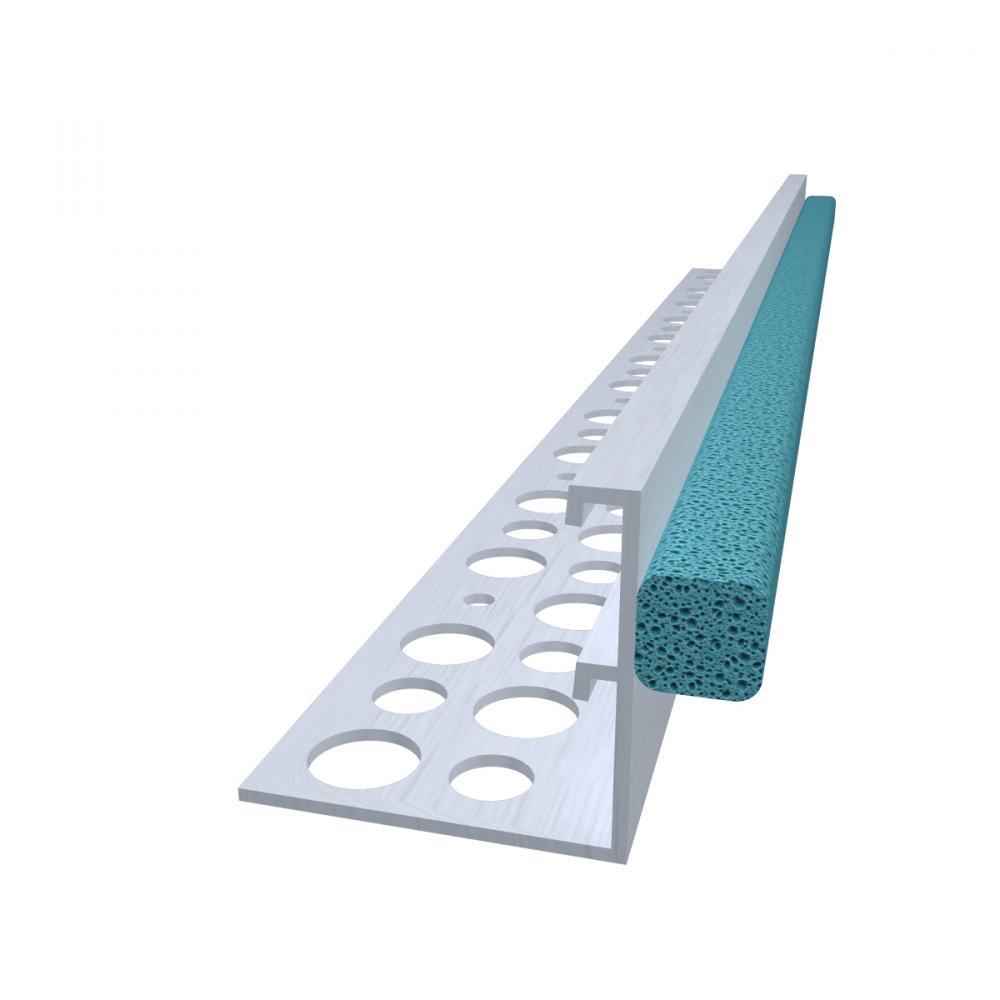

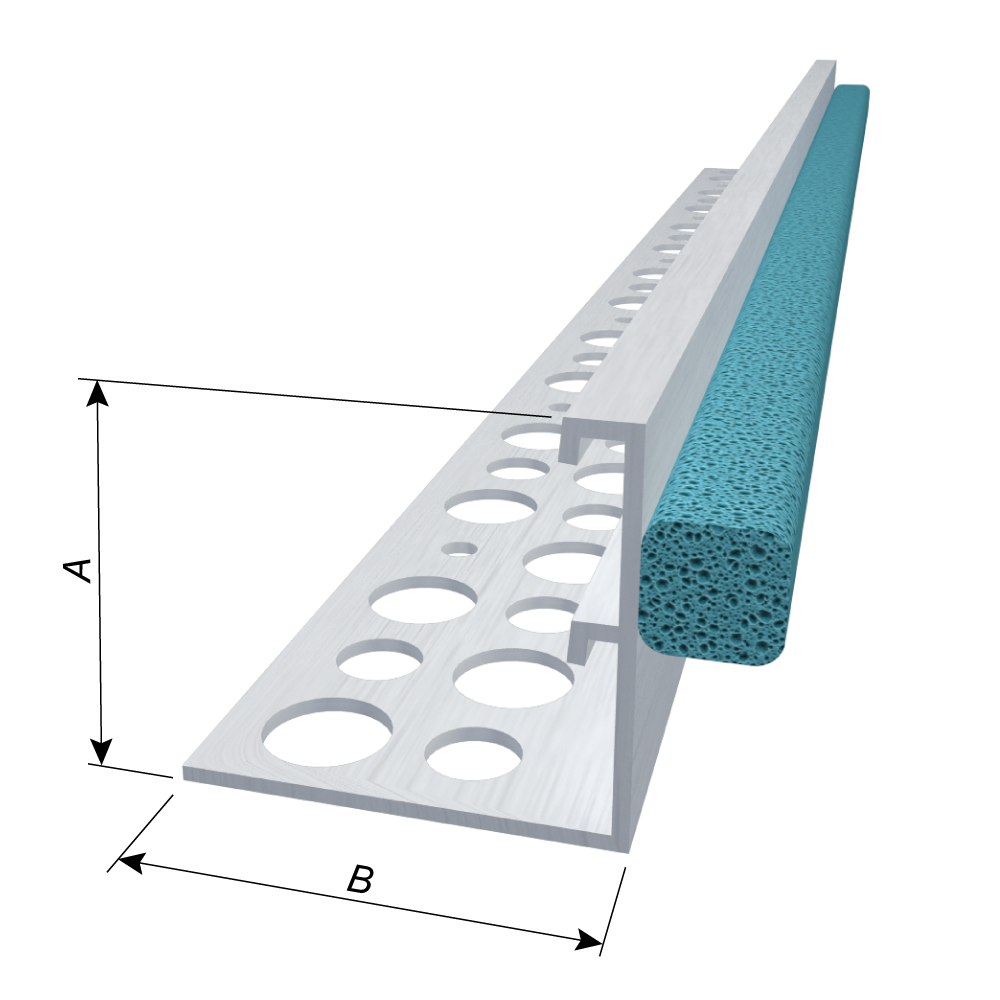

Casing Bead with factory applied blue backer rod

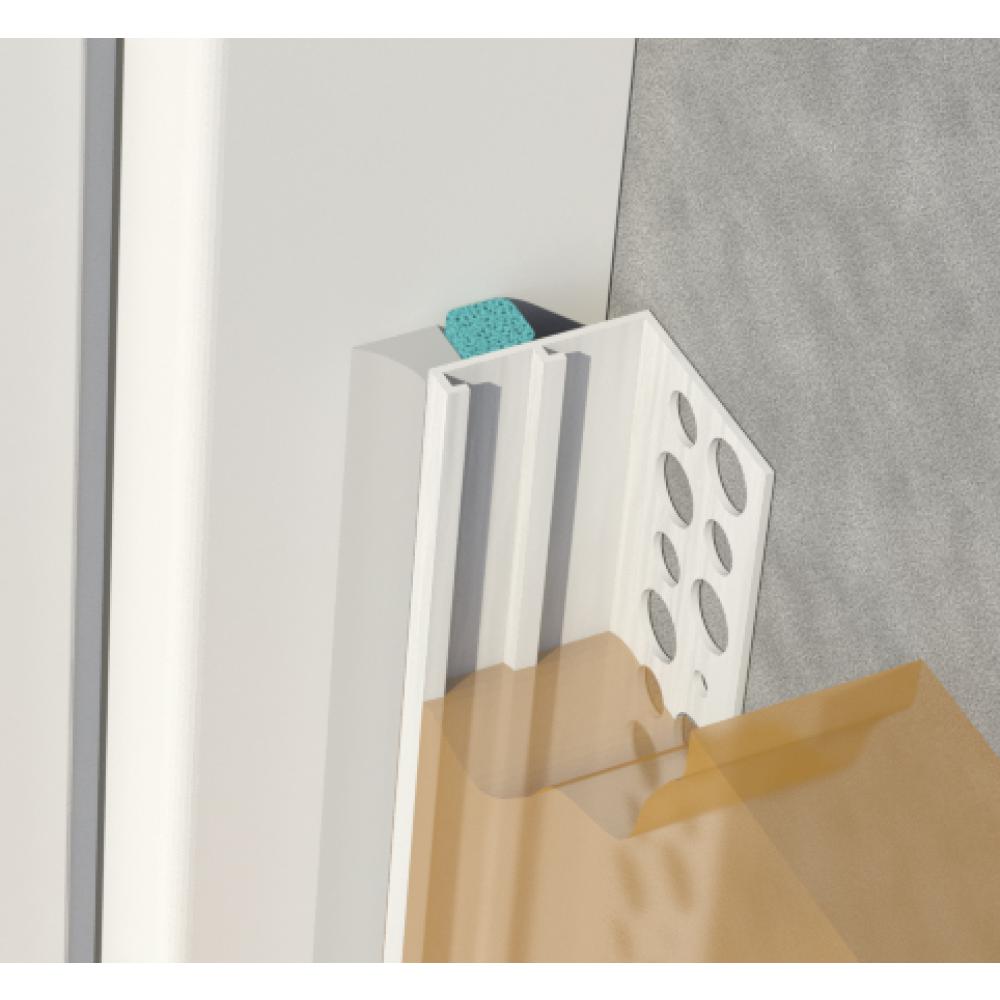

BackerBead® with Short Flange is perfect for situations where the standard 1-3/4" flange size is too large for the application. Factory-applied blue backer rod with preset width and depth to ensure proper caulk gap for sealant application. When the gap is properly caulked, the blue backer rod will no longer be visible.

Easy to install in tight areas such as recessed doors and windows, providing added moisture protection and a clean finish. A labor saving and quality control product for use at exterior openings in wet wall stucco applications.

To properly assemble a wall cladding system using stucco or manufactured stone veneer, the best practice is to maintain a "gap" around door and window openings and install a backer rod with compatible sealant in order to keep moisture out. The use of BackerBead® ensures that the correct caulk gap will be created around all door and window openings on exterior walls. The gap is predetermined by the factory-applied, closed-cell backer rod that is properly aligned and adhered to the vinyl casing bead. This approach eliminates the need to install the backer rod separately, saving time and ensuring a consistent, normal gap width and depth of 1/4" x 1/4". When installed and caulked properly, BackerBead® provides added protection from water penetration.

Vinyl is impervious to corrosion when coated in veneer plaster, wet joint compounds, or when placed in contact with steel or aluminum frames and resists impacts, dents, and damage during construction. No priming is required to add paint to vinyl products due to its paint adhesion properties. Vinyl has low electrical and thermal conductivity and is considered an excellent insulator, as well as being self-extinguishing and offering better resistance to burning than many other common building materials. Additionally, vinyl has a lower cost than equivalent products manufactured from zinc or aluminum, for use when the highest levels of corrosion resistance are required.

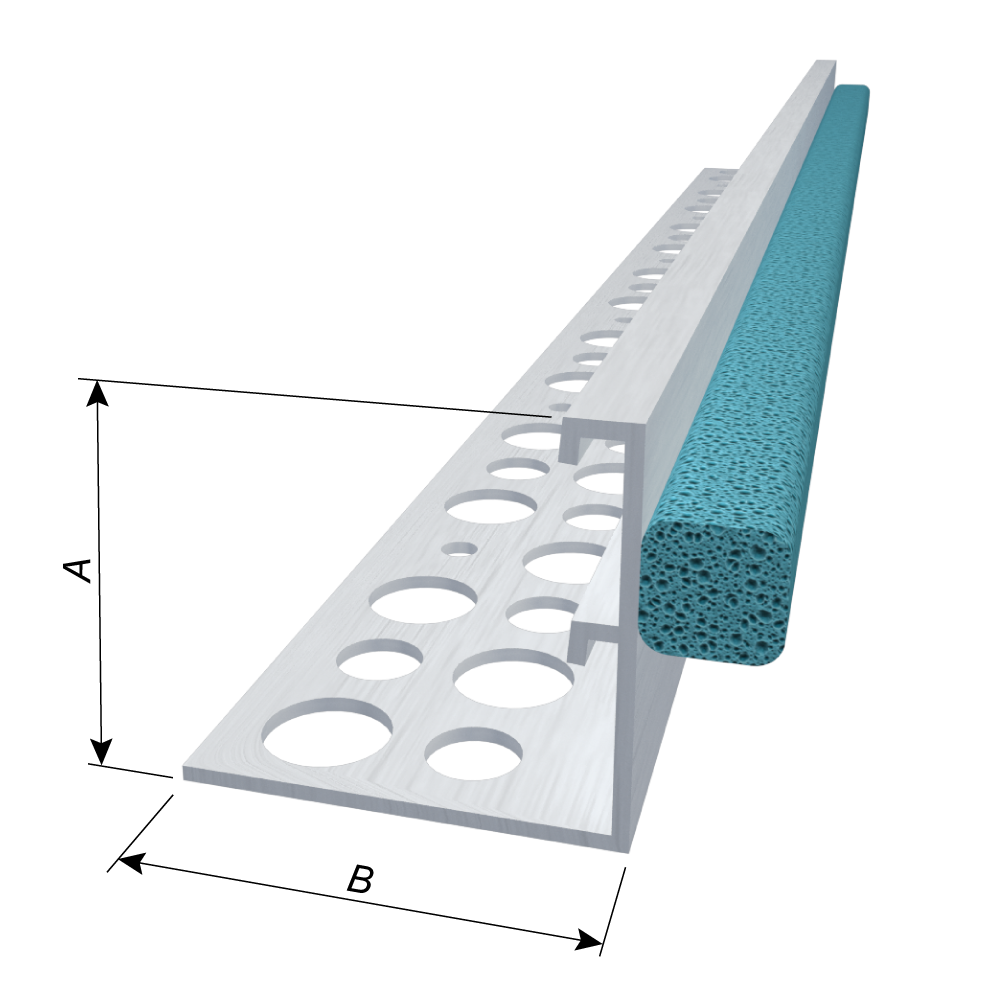

Product Data & Ordering Information

| Product code | Ground (A) | Flange (B) | Length | Pcs./Box |

|---|---|---|---|---|

| 6658BBSF | 5/8" | 1" | 10' | 50 |

| 6678BBSF | 7/8" | 1" | 10' | 50 |

| 66125BBSF | 1-1/4" | 1" | 10' | 50 |

Lengths: All 10-foot long standard. Custom lengths upon request.

Colors: Available in white, tan, brown or gray.

Backer Rod: Blue standard, white backer rod optional (for clear sealants)

Product Notes:

- Factory applied 3/8" x 3/8" backer rod is adhered with set back of 1/4" from the leading edge of the ground on BackerBead casing bead products, unless noted.

- BackerBead also available with a solid flange upon request. Add U to product code, example: 6658BBSFU.

- Integral backer rod also available in white upon request for clear sealant applications. Add -WH to product code, example 6658BBSF-WH.

- U.S. Patent Number D761,971

Installation:

Prior to placing the BackerBead, clean all surfaces to receive the bead and remove any oil and moisture. Refer to sealant manufacturer’s recommendations.

caulking instructions

BackerBead® Instalación

Documents

Code Approvals & Performance Standards

- ASTM C1063 Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster

- ASTM C1330 Standard Specification for Cylindrical Sealant Backing for Use with Cold Liquid-Applied Sealants

- ASTM C1780 Standard Practice for Installation Methods for Cement-based Adhered Masonry Veneer

- ASTM C1861 Standard Specification for Lathing and Furring Accessories, and Fasteners, for Interior and Exterior Portland Cement-Based Plaster

- ASTM D1784 Standard Classification System and Basis for Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds

- ASTM D4216 Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) and Related PVC and Chlorinated Poly(Vinyl Chloride) (CPVC) Building Products Compounds

- ASTM E331 Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference

- SDS Vinyl Corp PVC Compounds

STORAGE

All stored materials shall be kept dry. Materials shall be stacked off the ground, supported on a level platform, and protected from the weather.

PRoduct submittal SHeets

Click the below Product Code to view Submittal/Tech Datasheet.

| Product Code | Description |

|---|---|

| 6658BBSF, 6678BBSF, 66125BBSF | BackerBead® with Short Flange |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about creating product submittals or using SubmittalPro.