Non-load bearing, 2-hour and 3-hour rated vertical wall assemblies

They provide fire-resistant protection between adjacent living units in apartment buildings, condominiums and townhouses.

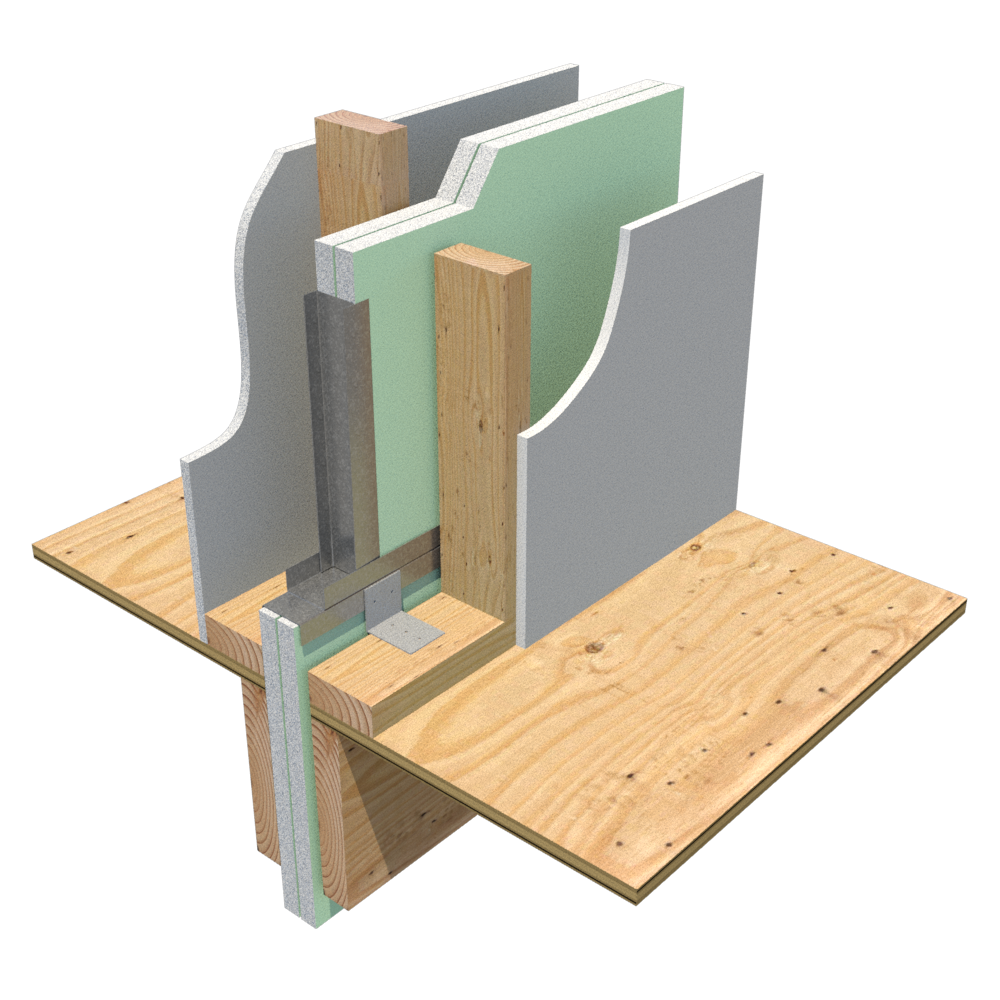

Area Separation Walls are non-load bearing, 2-hour and 3-hour rated vertical wall assemblies that provide fire-resistant protection between adjacent living units in apartment buildings, condominiums and townhouses. Area Separation Walls are also referred to as party walls, firewalls, multi-family walls and H-Stud assemblies.

Area Separation Walls are assembled between two independent walls to form a commonly shared party wall that extends from the foundation through the roofline. The walls are assembled with two-1" thick gypsum panel liners vertically installed between 2" H-Studs spaced 24" o.c. C-Runners are installed at the top and bottom of the walls and back-to-back between vertically stacked panels. Overall stacked area separation wall assembly cannot exceed 50 feet.

A photo of an Area Separation Wall system after a fire is shown to the right. Although this was a tragic event, it clearly proves the effectiveness of the Area Separation Wall system. The system performed as designed by maintaining the integrity of the fire wall protecting the lives and property of the adjacent units. (Photo courtesy of National Gypsum.)

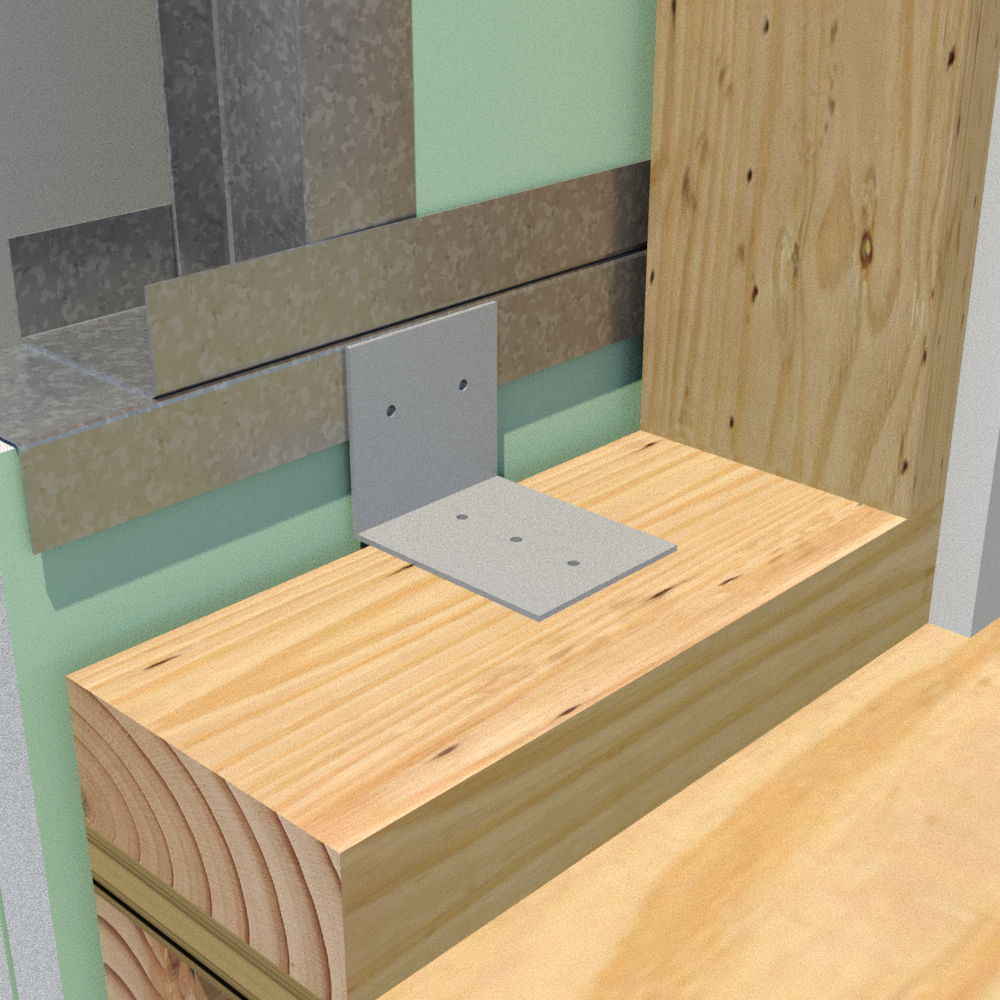

Aluminum Burn Clips are used to secure the Area Separation Wall in place to both sides of the floor, roof and truss line. The clips on the fire side are intended to melt under the intense heat during a fire, thus enabling a fire-damaged structure to collapse while keeping the fire wall barrier in place to protect the adjacent unit. This is commonly referred to as a "controlled collapse."

Area Separation Wall assemblies are a great alternative to masonry construction. The H-stud system is at least 50% lighter than masonry walls, installs faster, is STC sound rated and increases valuable floor space compared to 8" – 12" wide masonry walls.

ClarkDietrich H-Studs

ClarkDietrich H-Studs are 2" wide vertical members used to secure two 1" thick pieces of gypsum shaft liner in Area Separation Wall assemblies. H-Studs are inserted into C-Runners and slid over gypsum panel liner edges. The process is repeated until the desired wall length is achieved. Once the wall is plumbed it is secured at the floor, roof and truss line with Aluminum Breakaway Clips. Area Separation Wall assemblies are limited to 50 feet in height (maximum).

- 2-hour and 3-hour fire-rated assemblies

- 2" wide, 25 gauge (18mil)

- Tested and approved with most major gypsum and shaftliner manufacturers

- Stock lengths are 8', 10' and 12'

ClarkDietrich C-Runner

ClarkDietrich C-Runner is used to secure H-Stud and gypsum shaftliner panels in area separation wall assemblies. C-Runner is attached to the foundation with power-driven fasteners. C-Runner is also used as top track to cap the H-stud and gypsum shaftliner panels. A second track is then screwed back to back, to the lower runner, to hold the next level of the area-separation wall assembly.

- 2-hour and 3-hour fire-rated assembly

- 2-1/8" wide, 25 gauge (18mil)

- Tested and approved with most major gypsum and shaftliner manufacturers

- Standard 10' stock lengths

Aluminum Burn Clip (AB)

CLIPS MELT AWAY UNDER INTENSE HEAT, ALLOWING A FIRE-DAMAGED STRUCTURE TO COLLAPSE, WHILE KEEPING THE FIREWALL BARRIER IN PLACE TO PROTECT THE ADJACENT UNITS.

ClarkDietrich Aluminum Burn Clips are used as part of the ClarkDietrich H-Stud Area Separation Wall assembly and are designed to melt and break away when exposed to fire. The clips are used to hold the area separation wall assembly in place at the floor, roof and truss line between adjacent units.

Should a fire break out in one unit, the Aluminum Burn Clips on the fire-ridden side of the area-separation wall will melt, allowing the wall structure for that side to collapse. The Aluminum Burn Clips on the non-fire side will remain intact and hold the area separation wall in place as a barrier to contain the fire within the unit of origin.

Visit the Aluminum Burn Clip Product Page For more information.

FIRE-RATED SYSTEMS

2 Hour Design Assembly:

- Intertek Fire-Rated Design - 2 Hours, Non-Bearing Symmetrical Area Separation Wall

- LISTING INFORMATION of ClarkDietrich Steel 'H' Stud and 'U' Track Fire-resistance-rated Area Separation Wall Assemblies (9/7/16)

2 Hour UL Listings:

- U347 (1-3/8” flange) 2 hour

- U373 (1-1/2” flange) 2 hour

- U388 (1-3/8” flange) 2 hour

- V411 (1-3/8” flange) 2 hour

- U366 (1-3/8” flange) 2 hour

3 Hour Design Assemblies:

UL Design No. W454 (National Gypsum Co.)

(2) Layers of 1” thick gypsum board liner panels fit into H-Studs w/ (1) layer of 5/8” thick gypsum board on each side of wall assembly. Standard 2-1/2” long Aluminum Breakaway Clips can be used to secure assembly

UL Design No. W467 (CertainTeed Gypsum)

(2) Layers of 1” thick gypsum board liner panels fit into H-Studs w/ (1) layer of 5/8” thick gypsum board on each side of wall assembly. Standard 2-1/2” long Aluminum Breakaway Clips can be used to secure assembly

GA File No. ASW-2600 (USG Corporation)

(2) Layers of 1” thick gypsum board liner panels fit into H-Studs w/4" min aluminum burn clips required to accommodate the 2" mineral insulation

GA File No. ASW-2601(GP Gypsum Corporation)

(2) Layers of 1” thick gypsum board liner panels fit into H-Studs w/4" min aluminum burn clips required to accommodate the 2" mineral insulation

*** Reference design assemblies and gypsum board manufacturer for details of the wall system ***

Installation

*** Reference design assemblies and gypsum board manufacturer for details of the wall system ***

- Install the C-Runners along the floor in the desired position.

- An additional track is installed at the end of the wall

- Two 1" thick shaftliner panels are then inserted into the bottom and side tracks.

- An H-Stud is inserted into the lower track and slid over the edges of the shaftliner.

- Repeat steps 3 and 4 until the desired wall length is achieved.

- Cap the end and top of the wall with C-Runners.

- Confirm that the wall is plumb and then secure the assembly to the adjacent wall using Aluminum Breakaway Clips. Make sure to leave a 3/4" gap between the area separation wall and adjacent wall. Clip spacing is dependent on the height of the wall. Multiple wall assemblies can be stacked to a maximum height of 50 feet.

Note: Check listed Fire Rated Assembly Reports for details of construction, thickness and length of required burn clips.

Documents

Code Approvals & Performance Standards

- AISI S100-16 (2020) w/S2-20 North American Specification for the Design of Cold-Formed Steel Structural Members

- AISI S220-20 North American Standard for Cold-Formed Steel Framing - Nonstructural Members

- Intertek SPEC ID 26662 Area Separation Wall Assemblies

- SDS For ASTM A1003 Steel Framing Products For Interior Framing, Exterior Framing and Clips/Accessories

CAD Details

Note: to view all of ClarkDietrich's CAD details, visit the CAD Details Library.

PRoduct submittal SHeets

Click the below Product Code to view Submittal/Tech Datasheet.

| Product Code | Description |

|---|---|

| 2" 25ga | 2hr & 3hr Area Separation Wall Systems |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about creating product submittals or using SubmittalPro.