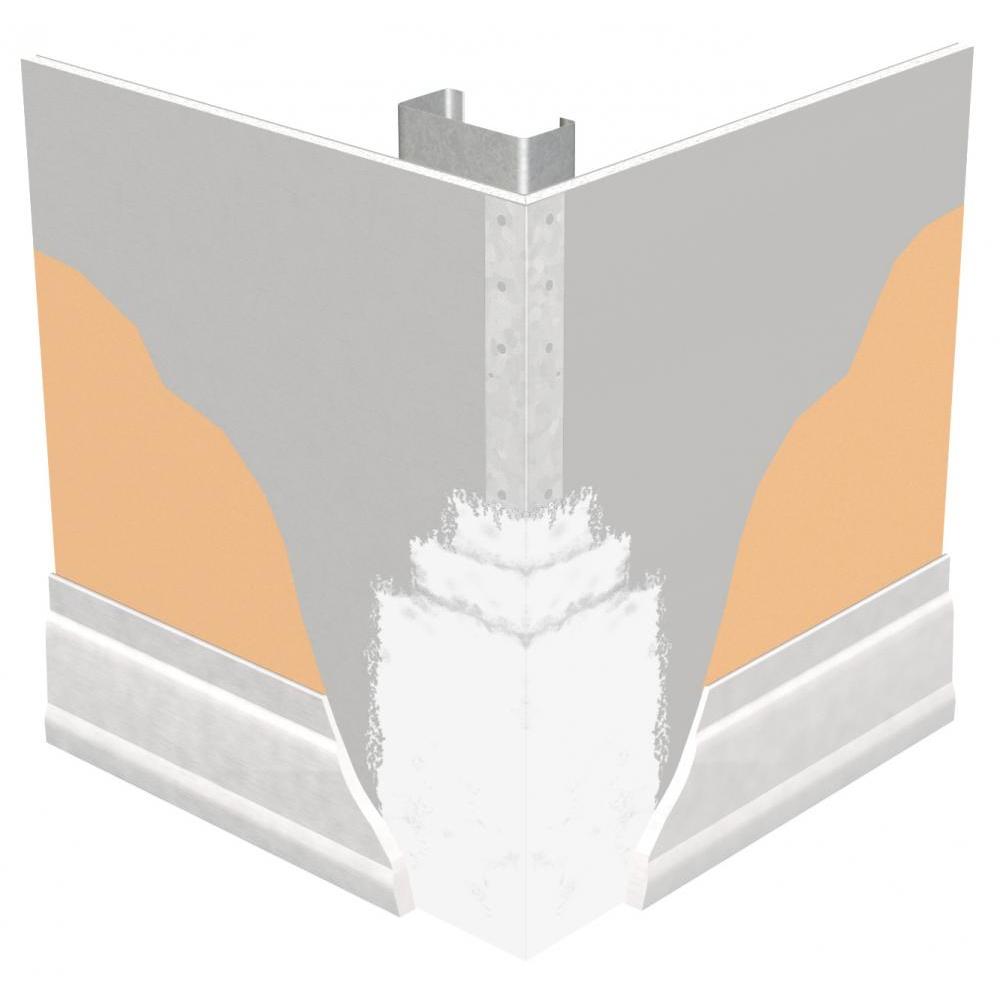

Hot-dipped steel reinforcement for long-lasting, corrosion-resistant drywall corner protection

Hot-dipped corner bead provided by Clinch-On Products, Co. offers the identical roll-formed precision as its counterpart.

Hot-dipped galvanized metal corner bead provides enhanced corrosion protection and sturdy reinforcement at exposed 90° corners. Flanges are knurled and perforated to ease joint compound adhesion and nail attachment. Hot-dipped galvanized metal meets ASTM C1047.

(Clinch-On® Beads are available in the East Coast only)

- Clinch-On Products, Co. provides premium, high-quality finishing beads and trims

- Sturdy metal reinforcement for 90° drywall corners

- Hot-dipped galvanized for corrosion protection

Material: 0.0125 min thickness, G30 galvanized

Product Data & Ordering Information

| Product code | Width | Length | Pcs./Ctn. |

|---|---|---|---|

| CBCS | 1-1/4" x 1-1/4" | 6' 9" | 75 |

| 1-1/4" x 1-1/4" | 7' | 75 | |

| 1-1/4" x 1-1/4" | 8' | 63 | |

| 1-1/4" x 1-1/4" | 9' | 56 | |

| 1-1/4" x 1-1/4" | 10' | 50 | |

| 1-1/4" x 1-1/4" | 12' | 50 |

INSTALLATION

Metal corner beads can be installed using a variety of methods. You may choose to do a combination of all three.

For regular metal corner bead, the drywall does not need to be set back.

Method 1: Staples

- Measure the wall height and subtract ½”. Measure and cut the corner bead using aviator snips. Dry fit to ensure accuracy.

- Position the bead on the corner and staple each mud flange every 6” to 10” with ½” staples.

- Using an 8” taping knife, apply the first coat of joint compound to the surface of the corner bead. The use of lightweight or setting-type compound in this step will reduce shrinkage and speed up drying time. Let this dry completely, for several hours or overnight.

- Using an 8” or 10” taping knife, apply a light finish coat of joint compound. Feather the compound beyond the previous coat. The use of all-purpose or topping compound will make for a more durable finish. Let this dry completely, for several hours or overnight.

- Sand lightly with 120 grit sandpaper.

Method 2: Screws or Nails

- Measure the wall height and subtract ½”. Measure and cut the corner bead using aviator snips. Dry fit to ensure accuracy.

- Position the bead on corner and fasten the bead with screws or nails using the smaller nail holes on each mud flange.

- Using an 8” taping knife, apply the first coat of joint compound to the surface of the corner bead. The use of lightweight or setting-type compound in this step will reduce shrinkage and speed up drying time. Let this dry completely, for several hours or overnight.

- Using an 8” or 10” taping knife, apply a light finish coat of joint compound. Feather the compound beyond the previous coat. The use of all-purpose or topping compound will make for a more durable finish. Let this dry completely, for several hours or overnight.

- Sand lightly with 120 grit sandpaper.

Method 3: Clinch-On Tool

- Measure the wall height and subtract ½”. Measure and cut the corner bead using aviator snips. Dry fit to ensure accuracy.

- Position the bead on the corner. Place the clinch-on tool over the bead.

- Hit the tool with a rubber mallet to crimp the bead to the corner, repeating every 8” to 10” for optimum fastening.

- Using an 8” taping knife, apply the first coat of joint compound to the surface of the corner bead. The use of lightweight or setting-type compound in this step will reduce shrinkage and speed up drying time. Let this dry completely, for several hours or overnight.

- Using an 8” or 10” taping knife, apply a light finish coat of joint compound. Feather the compound beyond the previous coat. The use of all-purpose or topping compound will make for a more durable finish. Let this dry completely, for several hours or overnight.

- Sand lightly with 120 grit sandpaper.

Code Approvals & Performance Standards

- ASTM C1047 Standard Specification for Accessories for Gypsum Wallboard and Gypsum Veneer Base

- SDS For ASTM A653 Steel Finishing Products For Interior Finishing and Exterior Finishing

PRoduct submittal SHeets

Click the below Product Code to view Submittal/Tech Datasheet.

| Product Code | Description |

|---|---|

| CBCS | Clinch-On Hot-Dipped Corner Bead |

ClarkDietrich SubmittalPro®

Submittal sheets for the exact product you're looking for can be created by using ClarkDietrich's SubmittalPro® Product Submittal System.

- Contact ClarkDietrich Technical Services at 888-437-3244 for any questions about creating product submittals or using SubmittalPro.